Semiconductor process equipment and O-shaped ring thereof

A process equipment and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as loss of sealing effect, uncertain effective time of viscose 4, and influence on overall process yield, so as to prevent fluid leakage , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

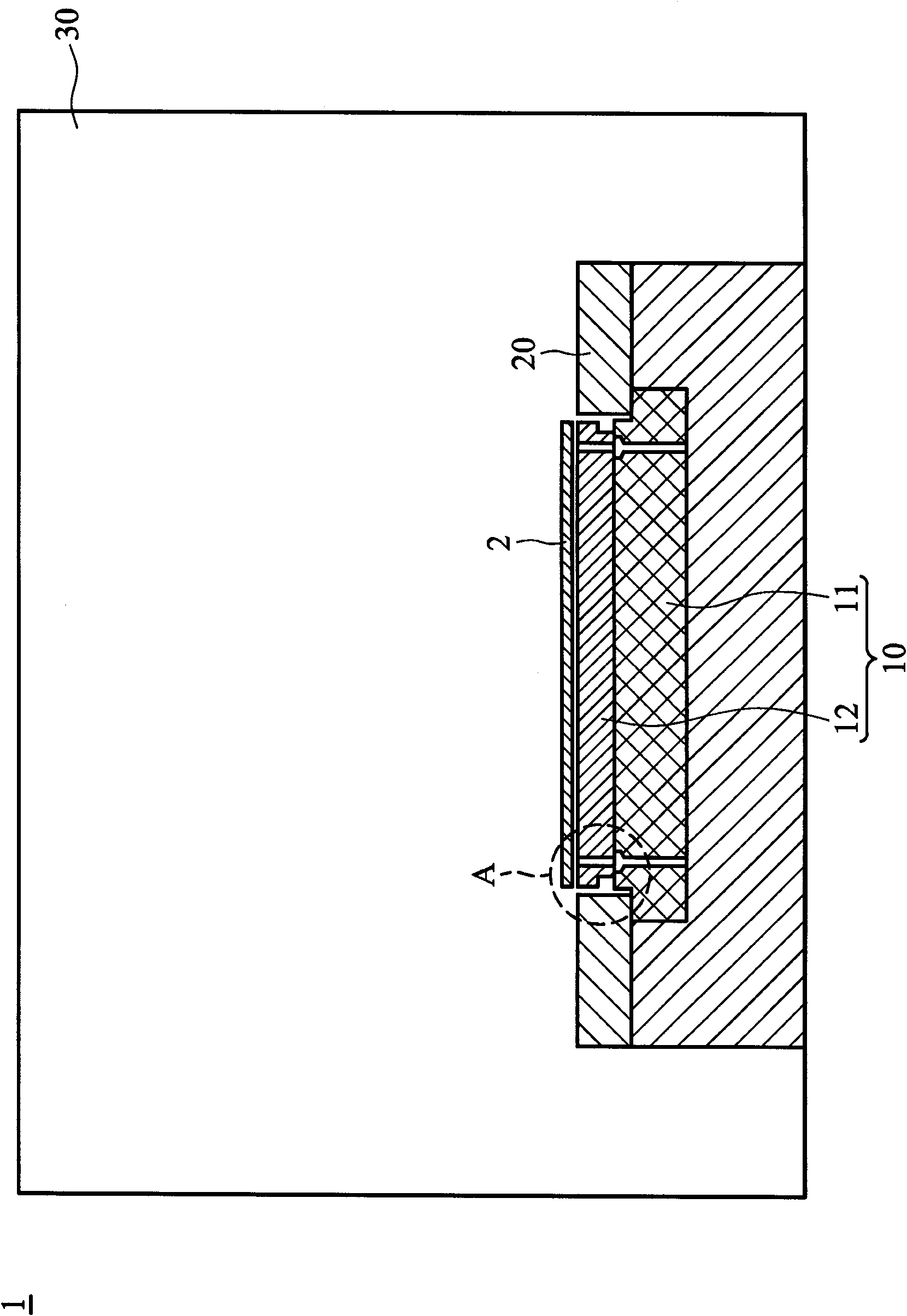

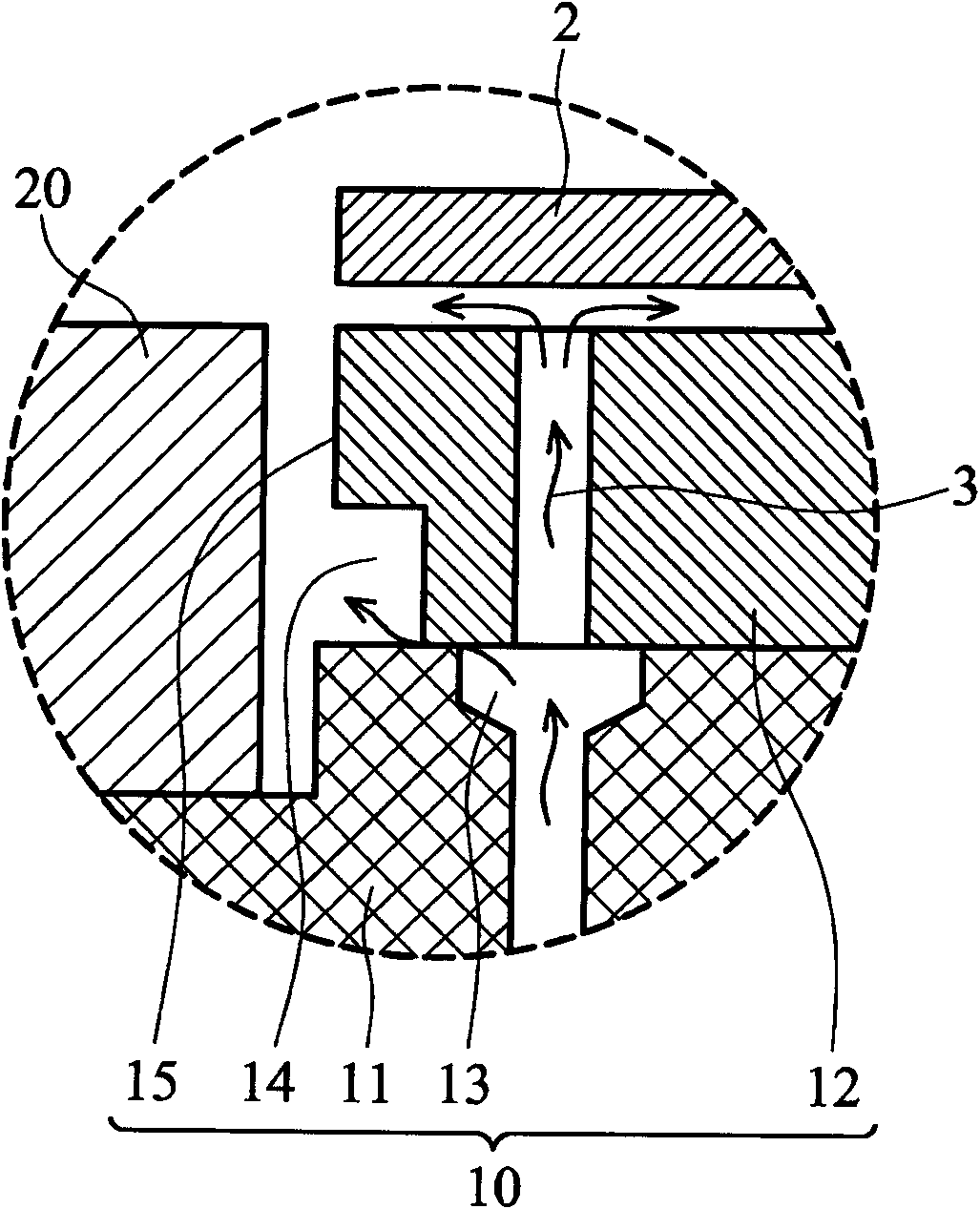

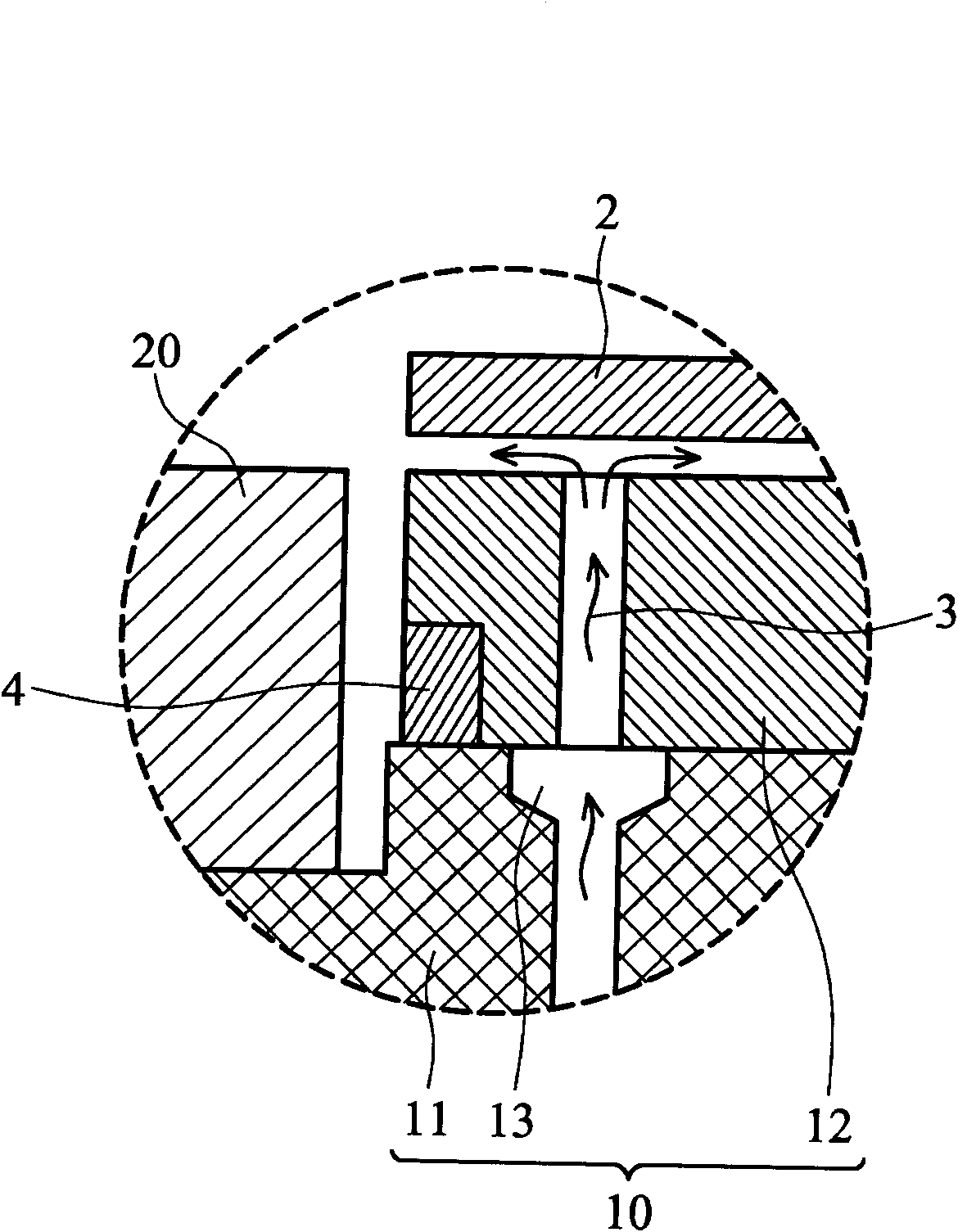

[0052] refer to Figure 2a , Figure 2b , which shows a semiconductor process equipment (plasma etching equipment) 100 according to the first embodiment of the present invention, which is used to perform a process on a wafer 2 . Figure 2b for Figure 2a Enlarged view of part A1 in. The semiconductor process equipment 100 includes a wafer base 10 , an extended covering element 20 , an O-ring (O-ring body) 110 and a cavity 30 . The crystal seat 10 is disposed in the cavity 30 . The crystal seat 10 includes a crystal seat body 11, a fluid supply unit 13 and a carrier element 12, the carrier element 12 is arranged on the crystal seat body 11, the wafer 2 is placed on the carrier element 12, the fluid supply The unit 13 is disposed in the base body 11 and provides a fluid 3 to the wafer 2 through the carrier element 12 . A groove 14 is formed on a side surface 15 of the crystal base 10 where the base body 11 and the carrier element 12 are connected. The extending covering el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com