Movable steel base for constructing prefabricated beam and standard joint thereof

A technology of standard sections and prefabricated beams, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of long construction time and high manufacturing cost of concrete pedestals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

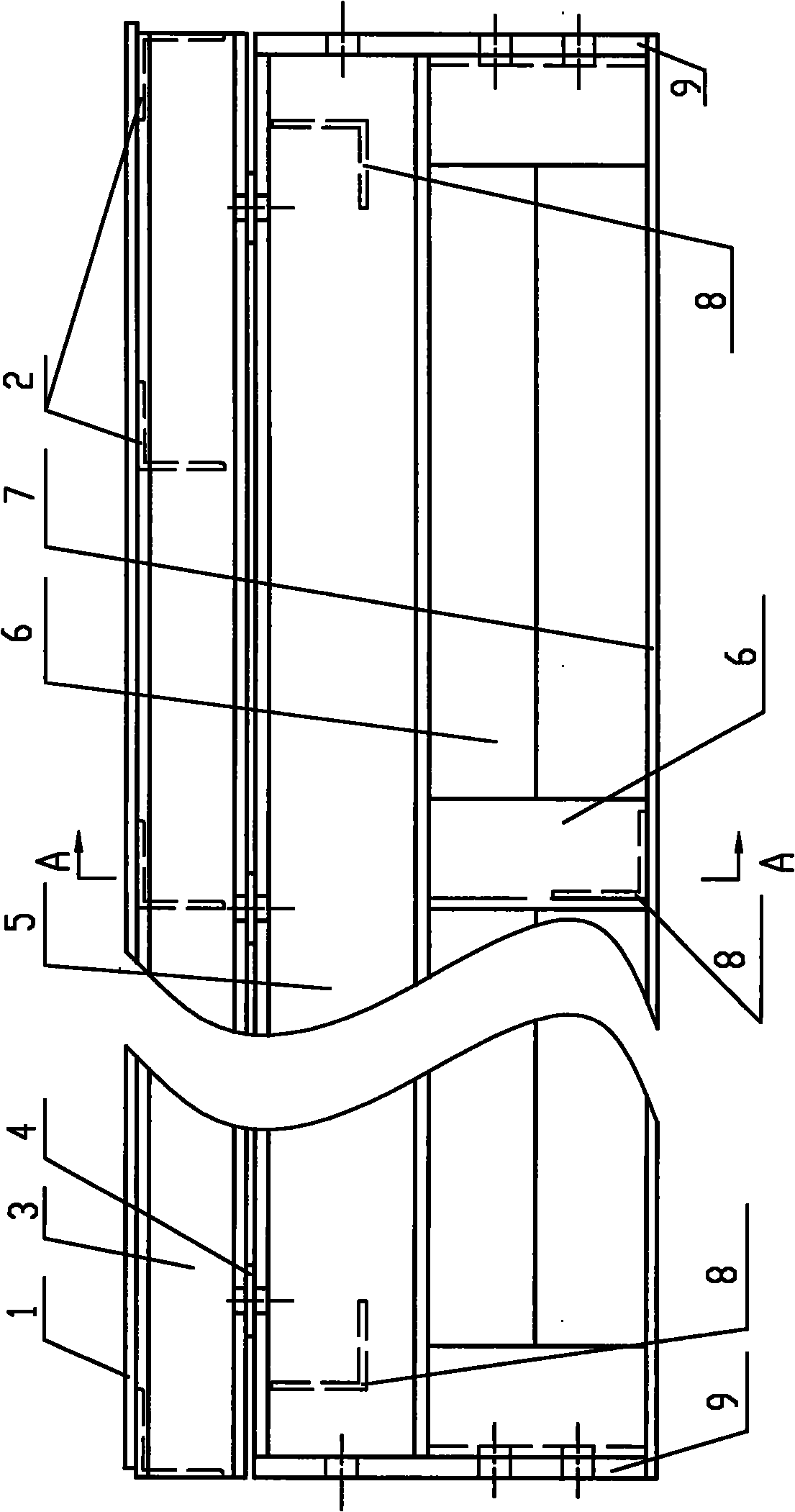

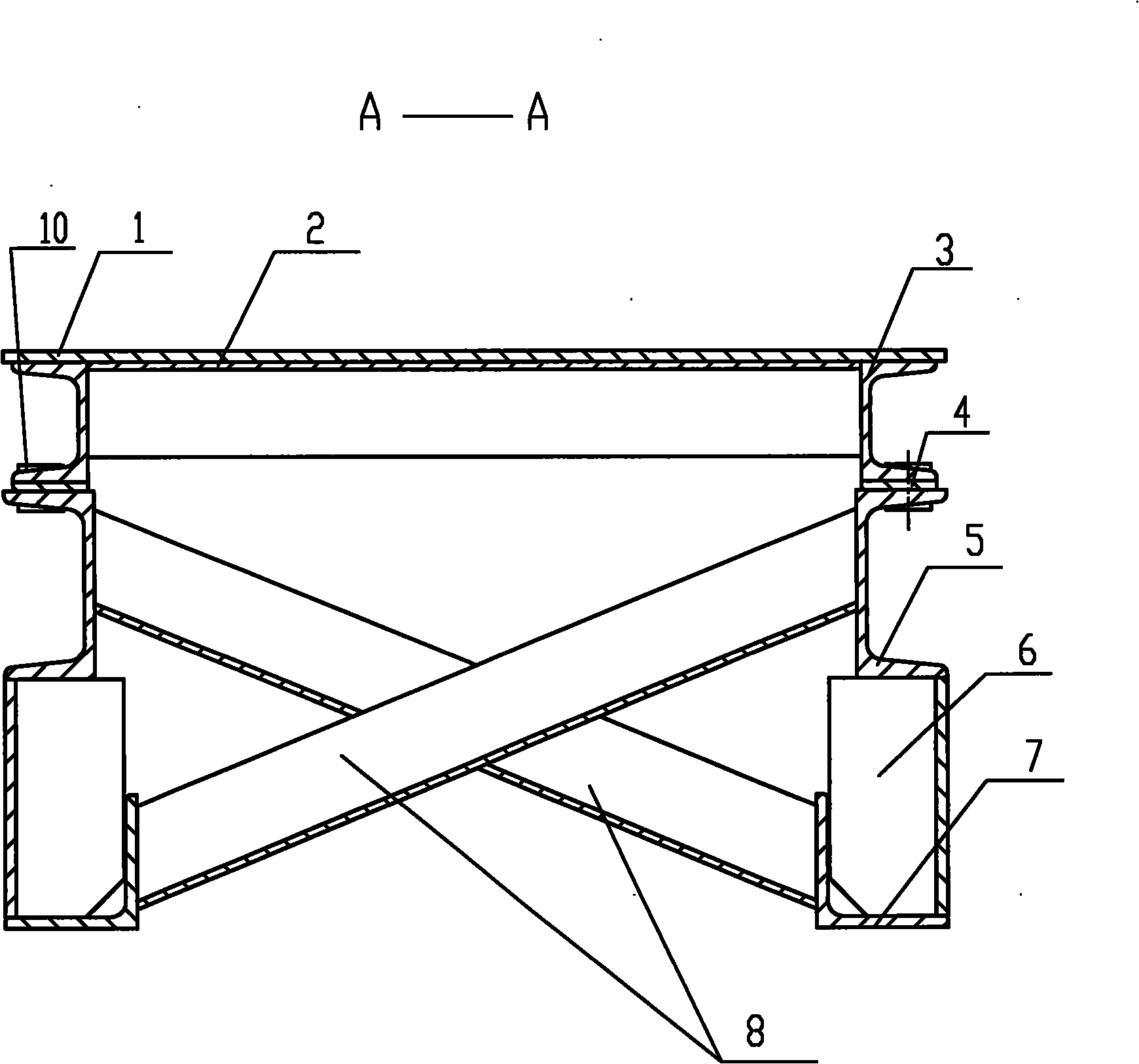

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

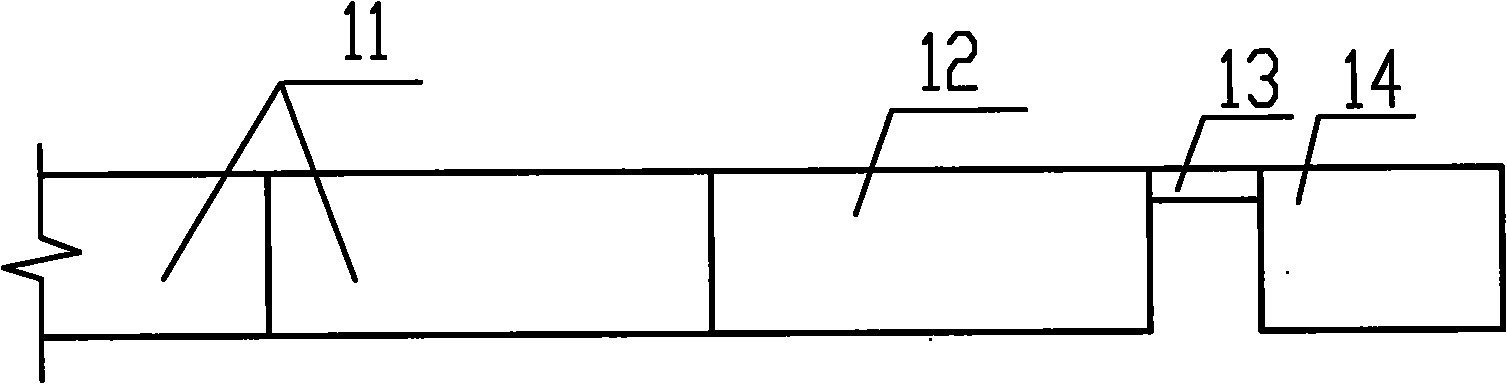

[0026] See attached figure 2 , each standard section is structurally divided into two parts, the upper part is the beam bottom formwork part, including the first steel plate 1, the first channel steel 3 and the first angle steel 2; the lower part is the supporting seat part, the structure includes the second angle steel 7, the first angle steel Triangular steel 6, second channel steel 5, fourth angle steel 8 and third steel plate 9. Spot welding connection between the first steel plate 1 and the first channel steel 3 below and the first angle steel 2, the first channel steel 3 is arranged on both sides of the first steel plate 1, and the first channel steel 3 is plugged with a rubber tube to prevent The grout leaks here when the beam concrete is poured, and the first angle steel 2 is welded between the first channel steels on the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com