Method for preparing high viscosity polyanionic cellulose

A polyanion and cellulose technology, applied in the field of polyanion cellulose preparation, can solve the problems of high fluid loss, poor salt tolerance, low viscosity of polyanion cellulose, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

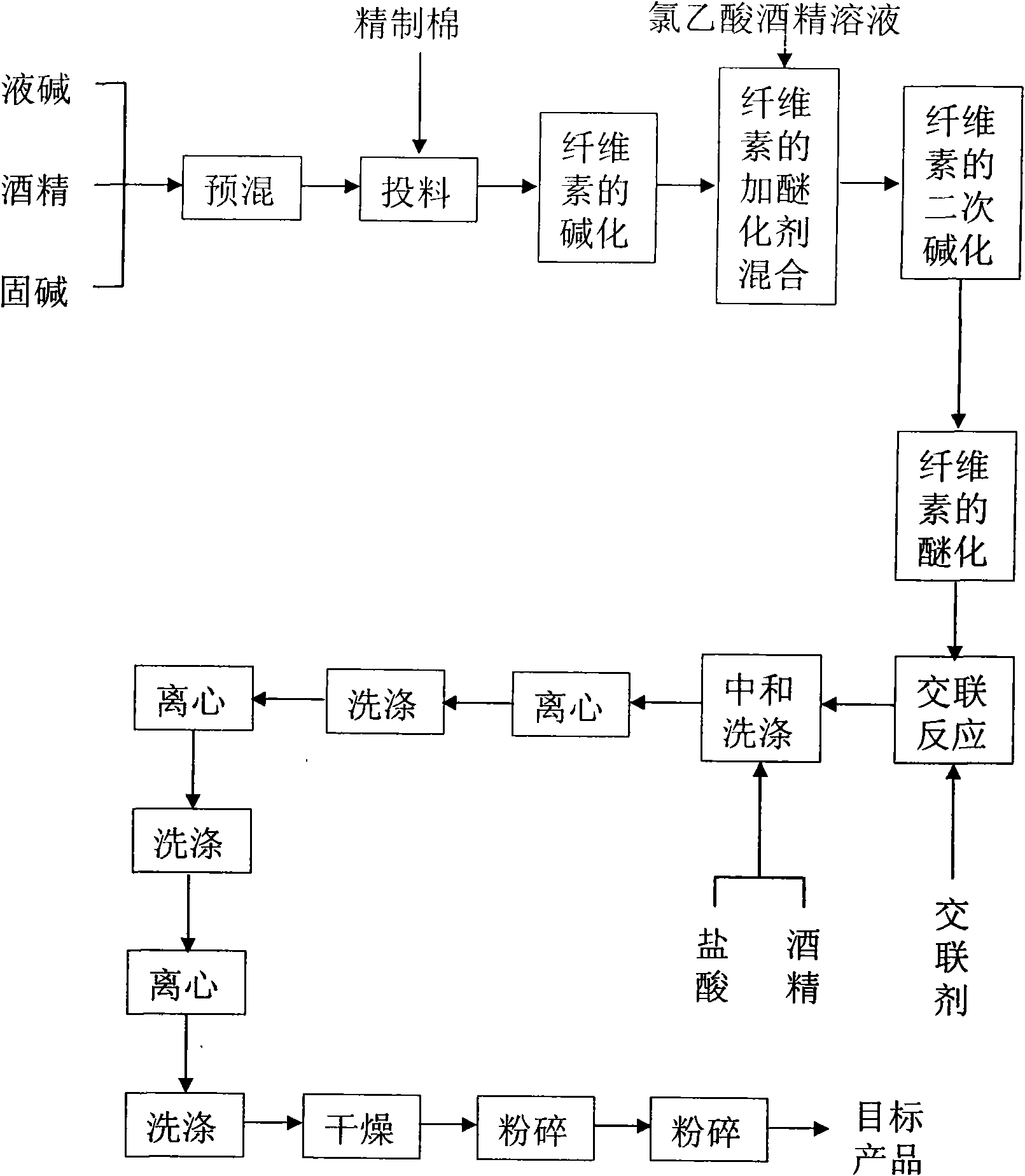

[0025] see figure 1 . The preparation method of high-viscosity polyanionic cellulose specifically comprises the following steps:

[0026] 1) Premixing: In the kneader, add solid alkali, liquid alkali and alcohol, premix for 10min-30min, so that the solid alkali is basically dissolved in liquid alkali and alcohol. The use of alkali in two forms of matter is mainly to control the moisture in the reaction and reduce the occurrence of side reactions.

[0027] 2) Feeding: After premixing, put the shredded refined cotton into the kneader. The average degree of polymerization of the refined cotton is 2000-4000.

[0028] 3) Alkalinization of cellulose: Add liquid caustic soda and alcohol into the kneader by spraying for alkalization of cellulose. During the entire alkalization process, the cooling water is used to control the temperature at 15°C-40°C. N 2 Protection, alkalization time is 30min-80min.

[0029] 4) Mixing of cellulose with etherification agent: add chloroacetic acid...

Embodiment 2

[0059] The preparation method of high-viscosity polyanionic cellulose specifically comprises the following steps:

[0060] 1) Premixing: In the kneader, add 644g of liquid caustic soda with a concentration of 48.5%, 1300ml of alcohol with a concentration of 93% and 170g of solid caustic, and premix at a temperature of 20°C-40°C for 20 minutes to make the solid alkali basically Dissolve in caustic soda and alcohol.

[0061] 2) Feeding: After premixing, put 1200g of shredded refined cotton into the kneader. The average degree of polymerization of the refined cotton is 2000-4000.

[0062] 3), alkalization of cellulose: by spraying, 600g concentration is 48.5% liquid caustic soda and 1200ml concentration is 93% alcohol to join in the kneader, carry out the alkalization of cellulose, pass through in the whole alkalization process Control the temperature of cooling water at 15°C-40°C, pass N 2 Protection, alkalization time is 50min.

[0063] 4) Mixing of cellulose with etherifyin...

Embodiment 3

[0073] The preparation method of high-viscosity polyanionic cellulose specifically comprises the following steps:

[0074] 1) Premixing: In the kneader, add 626g of liquid caustic soda with a concentration of 49.5%, 1200ml of alcohol with a concentration of 95% and 170g of solid caustic, and premix at 20°C-40°C for 15 minutes to make the solid alkali basically Dissolve in caustic soda and alcohol.

[0075] 2) Feeding: After premixing, put 1200g of shredded refined cotton into the kneader. The average degree of polymerization of the refined cotton is 2000-4000.

[0076] 3), cellulose alkalization: 600g concentration is 49.5% liquid caustic soda and 1200ml concentration is 95% alcohol to join in the kneader by the mode of spraying, carries out the alkalization of cellulose, pass through in the whole alkalization process Control the temperature of cooling water at 15°C-40°C, pass N 2 Protection, alkalization time is 60min.

[0077] 4) Mixing of cellulose with an etherifying ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com