Hot-rolling analogue device and rolling history recording analogue method

A technology of historical records and simulation devices, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as time-consuming, complicated calculations, and no consideration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0028] "Outline of Hot Rolling Simulator 100"

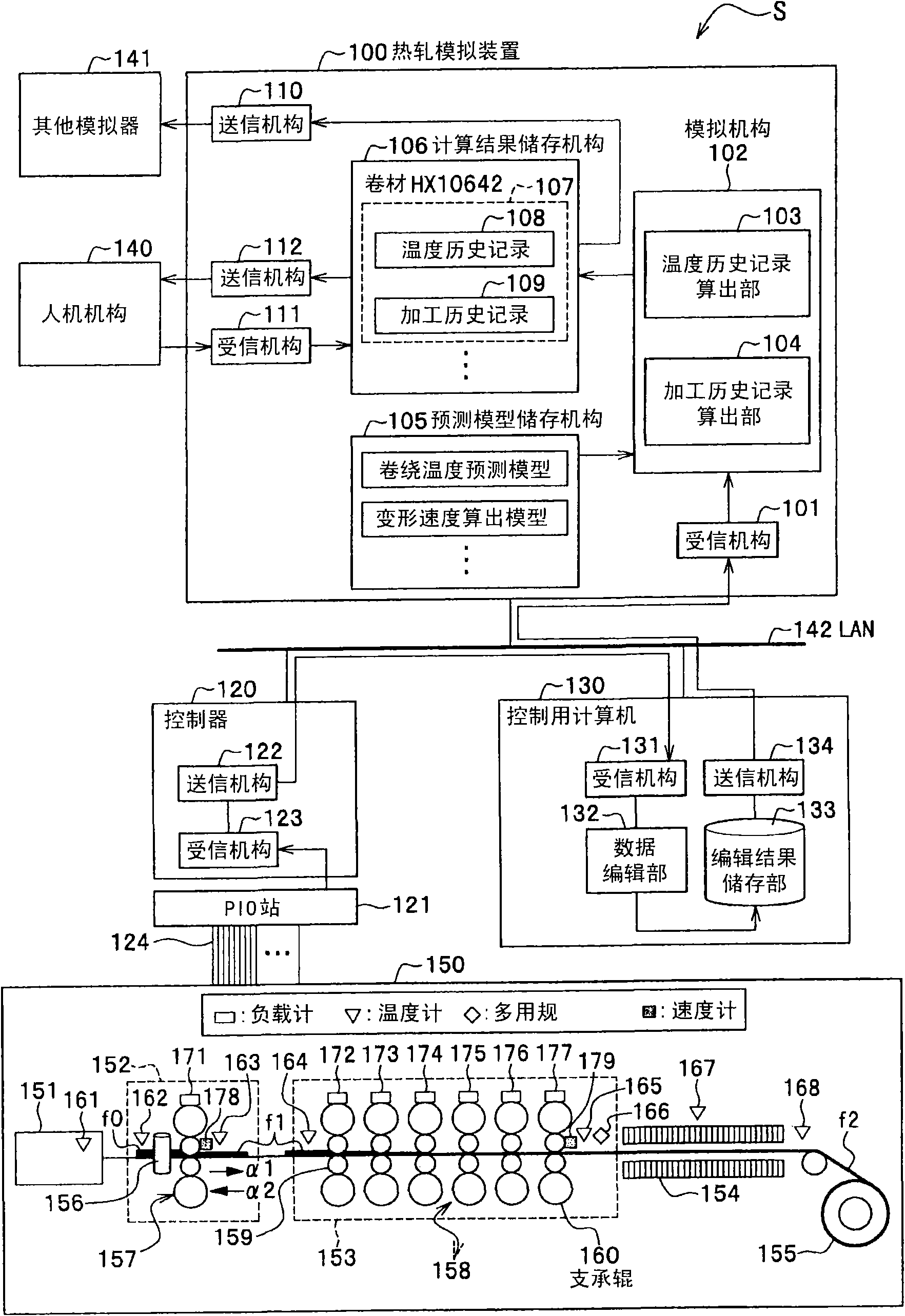

[0029] figure 1 It is a conceptual diagram showing the hot rolling simulation system S including the hot rolling simulation device 100 of the embodiment.

[0030] The hot-rolling simulation device 100 according to the embodiment performs the process of drawing out a slab f0 as a rolled plate before rolling to a hot-rolled steel plate f2 rolled through a rolling process in the rolling facility of the control object 150 . It is a device for simulating temperature history or processing history in each part of the hot-rolled flat steel plate f (f0, f1, f2) between coiling and coiling of the down coiler 155 .

[0031] The hot rolling simulator 100 integrates detection information from measuring devices such as thermometers 161 to 165, 167, and 168 or load gauges 171 to 177 installed at points in each rolling process, and uses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com