Screw-free socket

A technology without screws and sockets, which is applied in the direction of contact parts, electrical components, and devices for connecting/disconnecting parts. The effect of a reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

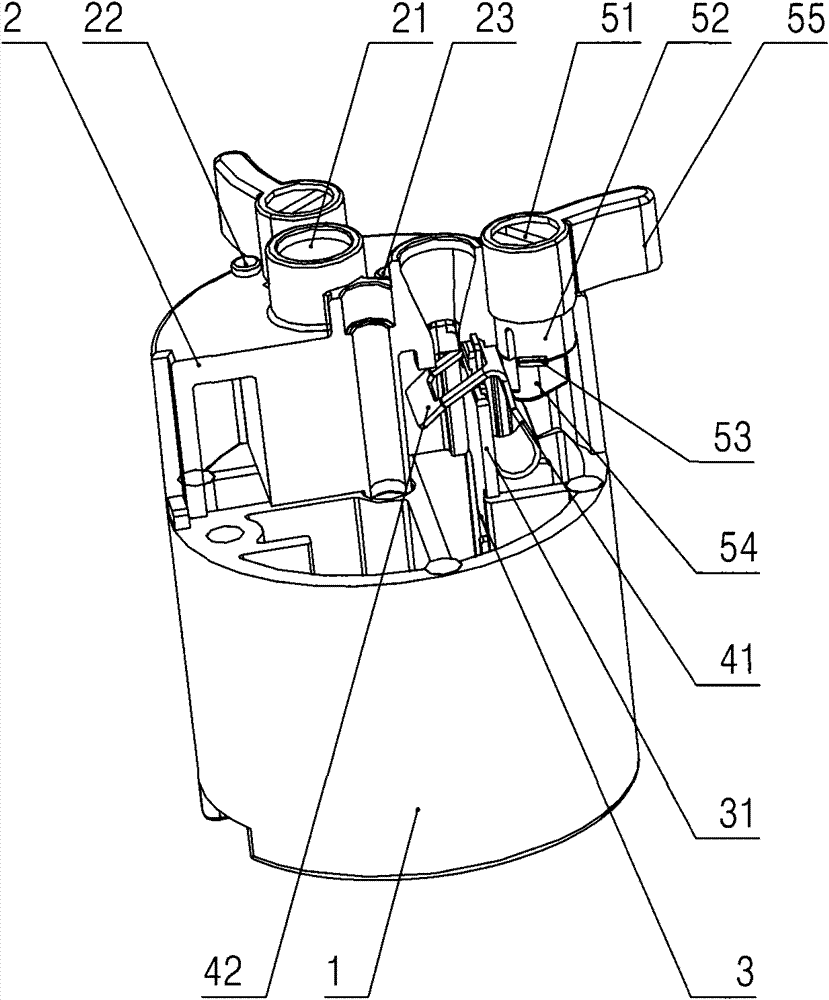

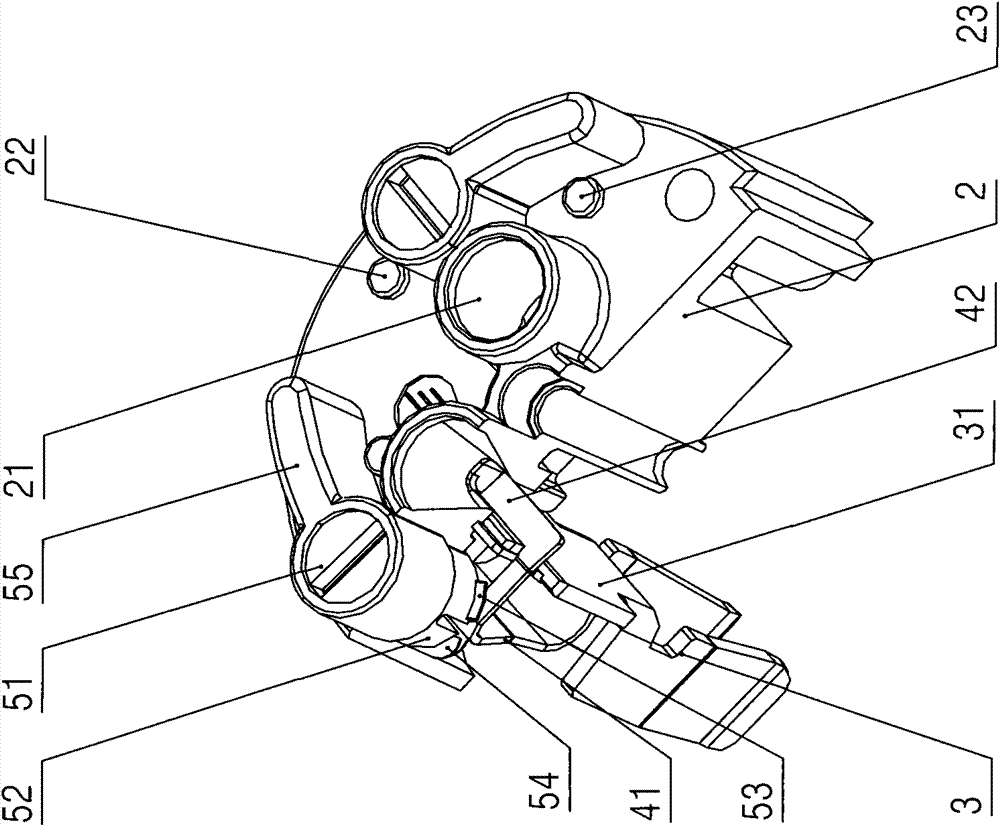

[0011] Such as figure 1 , figure 2 As shown, the screwless socket of the present invention includes: upper and lower covers 1 and 2 and three sockets 3 arranged in the upper and lower covers 1 and 2, and the lower cover 2 is provided with three "J" A font-shaped elastic lug and three toggle levers. The elastic lug includes: a reed 41 and a lug 42 located at the top of the reed 41. The lug 42 is provided with a wiring hole for threading, and the plug sleeve 3 The top is provided with a clamping plate 31, the clamping plate 31 extends into the wiring hole of the lug 42, the lower end of the reed 41 leans against the clamping plate 31, and the end surface of the lower cover 2 is provided with a corresponding matching hole for the wiring. The wire insertion hole 21 and the toggle hole corresponding to the reed 41, the circumferential surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com