Profiled fiber and spinneret plate and preparation method thereof

A special-shaped cross-section and spinneret technology, which is applied in fiber processing, short fiber formation, textiles and papermaking, etc., to achieve the effects of increasing specific surface area, accelerating liquid evaporation, and novel cross-sectional characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

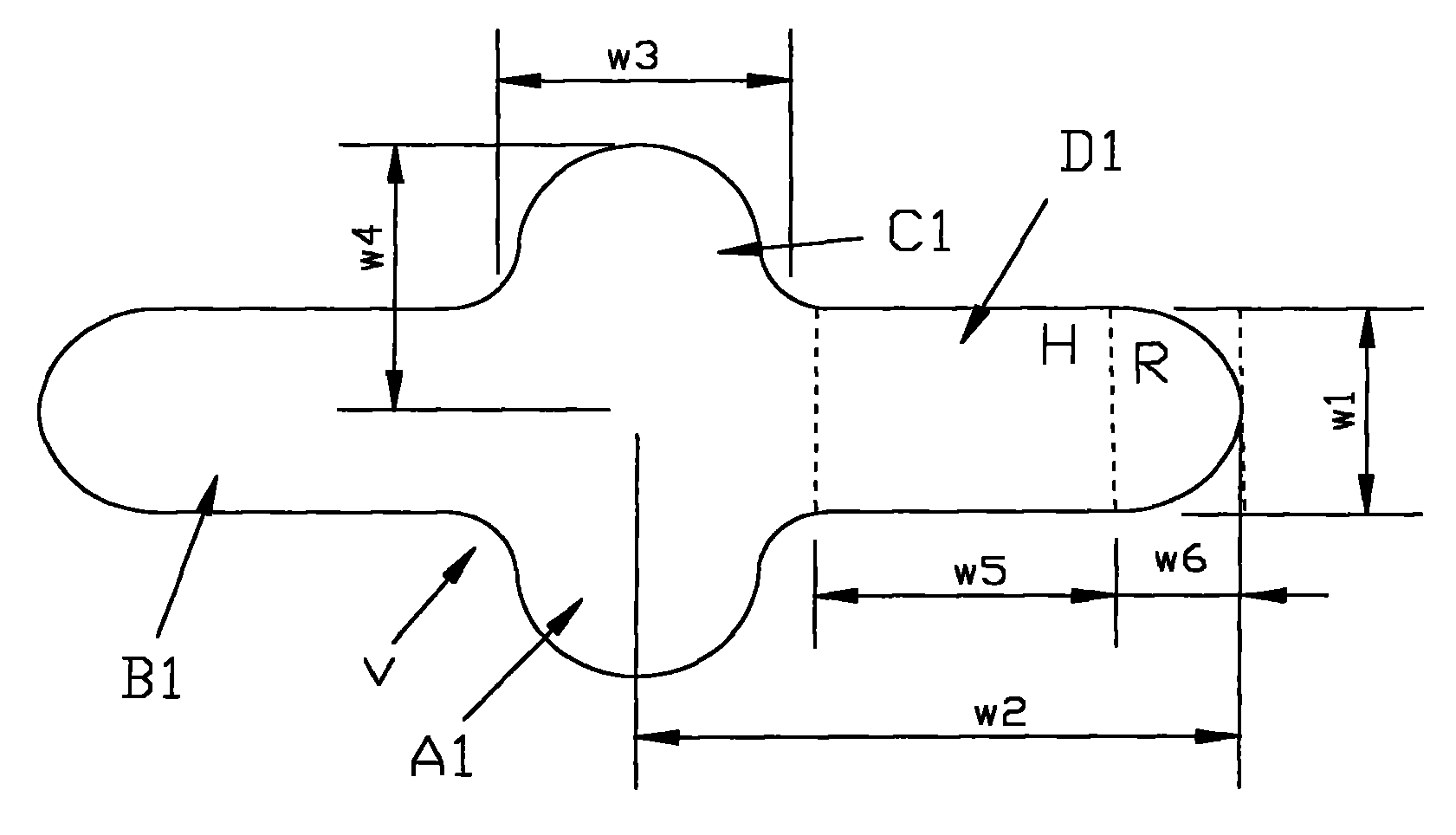

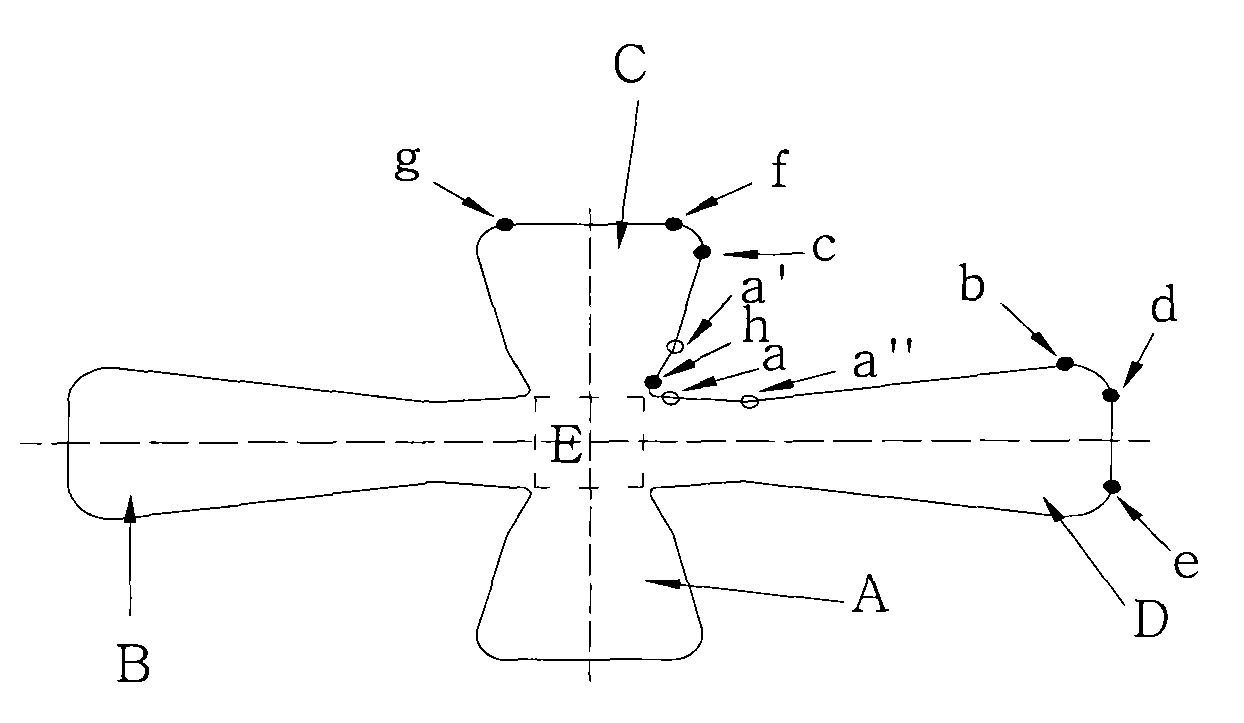

[0076] The spinneret hole size used was the data shown in Table 1a. PET chips with an intrinsic viscosity of 0.680dl / g are used. The spinning and drawing equipment adopts a common single-screw melt spinning machine and a common hot roller drawing machine. The spinning process parameters are shown in Table 1b, and the drawing process parameters are shown in Table 1c. The properties of the fibers are listed in Table 1d. Both the spinneret hole and the spinning process have adopted the conditions in the invention, and the fiber shape and performance have reached the conditions in the invention.

[0077] Table 1a. Spinning hole size of Example 1

[0078] project

parameters

The ratio of the height to the upper base of the smallest circumscribed trapezoid T of leaf A(C)

1.3

The ratio of the height to the upper base of the smallest circumscribed trapezoid T of leaf B(D)

4.5

The ratio of the height of the smallest circumscribed trapezoid T o...

Embodiment 2

[0086] The spinneret hole size used is the data shown in Table 2a. PET chips with an intrinsic viscosity of 0.668dl / g are used. The spinning and drawing equipment adopts a common single-screw melt spinning machine and a common hot roller drawing machine. The spinning process parameters are shown in Table 2b, and the drawing process parameters are shown in Table 2c. The properties of the fibers are shown in Table 2d. Both the spinneret hole and the spinning process have adopted the conditions in the invention, and the fiber shape and performance have reached the conditions in the invention.

[0087] Table 2a. Spinning hole size of Example 2

[0088] project

parameters

The ratio of the height to the upper base of the smallest circumscribed trapezoid T of leaf A(C)

1.5

The ratio of the height to the upper base of the smallest circumscribed trapezoid T of leaf B(D)

3.6

The ratio of the height of the smallest circumscribed trapezoid T of ...

Embodiment 3

[0096] The spinneret hole size used is the data shown in Table 3a. PET chips with an intrinsic viscosity of 0.665dl / g are used. The spinning and drawing equipment adopts a common single-screw melt spinning machine and a common hot roller drawing machine. The spinning process parameters are shown in Table 3b, and the drawing process parameters are shown in Table 3c. The properties of the fibers are shown in Table 3d. Both the spinneret hole and the spinning process have adopted the conditions in the invention, and the fiber shape and performance have reached the conditions in the invention.

[0097] Table 3a. Spinning hole size of Example 3

[0098]

[0099] The spinning process parameter of table 3b. embodiment 3

[0100] condition

parameters

Spinning temperature °C

281

Spinning speed m / min

3000

Number of spinneret holes

96

blowing method

outer ring blow

Blowing speed m / s

0.5

The distance between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com