Method for lubricating and cooling finish rolling side guide plate

A technology of side guide plate and cooling precision, applied in the field of steel rolling process, can solve the problems of scarring and edge crack defects, and achieve the effects of improving the surface quality of products, prolonging the replacement cycle and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

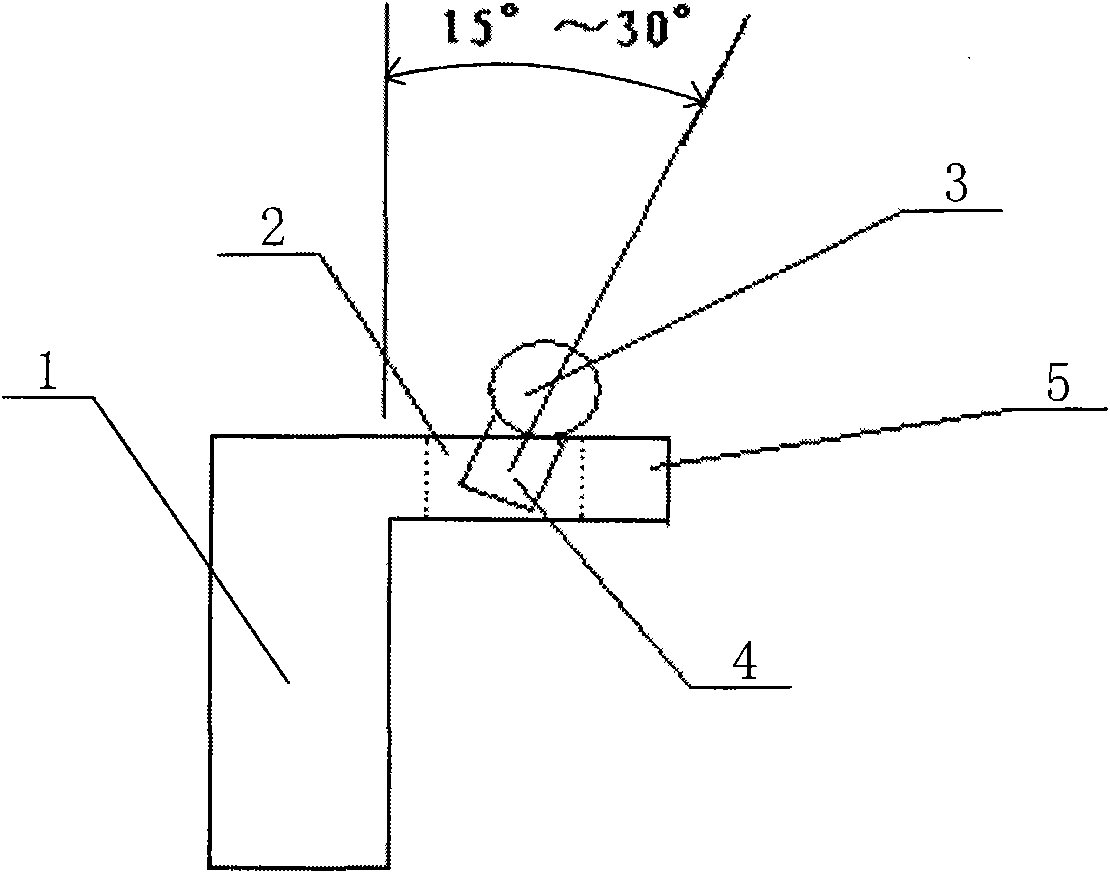

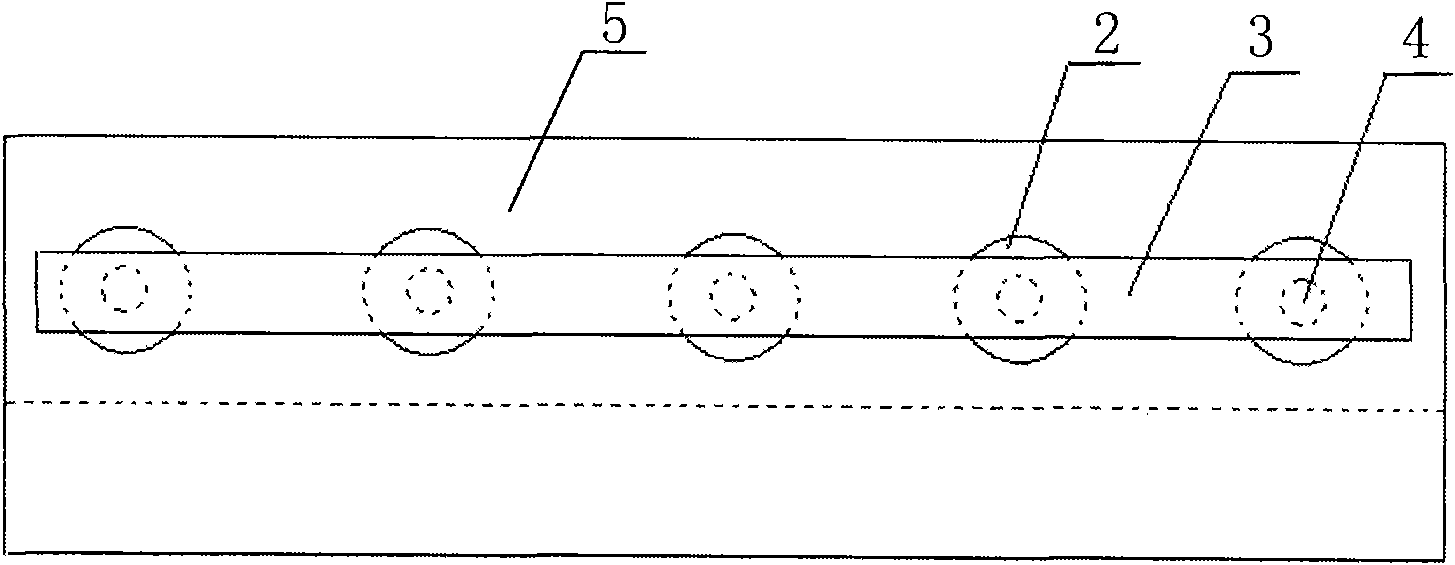

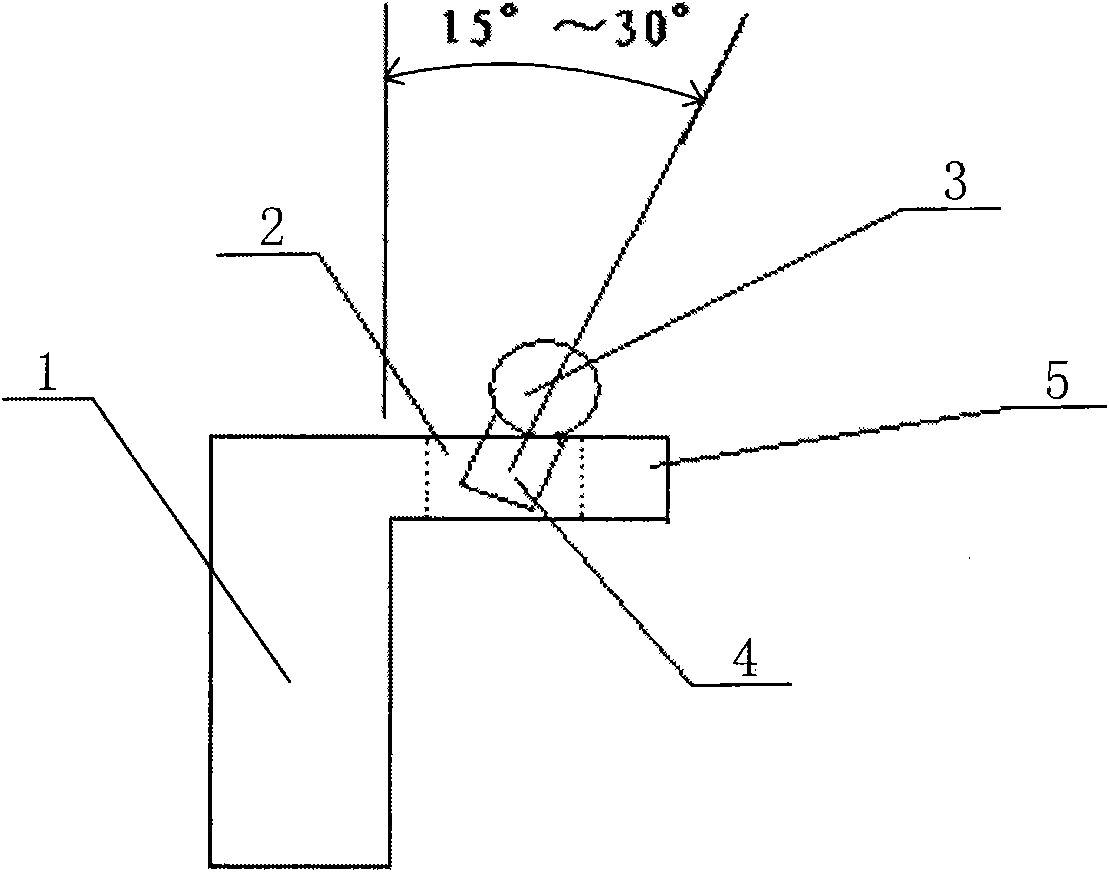

[0015] See figure 1 , figure 2 , a method for lubricating and cooling the finish rolling side guide plate, the method is to install a hot-rolled oil header 3 on the upper edge of the finish rolling side guide plate of the downstream stand of the finish rolling mill, and the hot-rolled oil header 3 is arranged in the same direction as the side guide plate 1 Parallel; multiple hot-rolling oil nozzles 4 are arranged on each hot-rolling oil header 3, so that the injection range of hot-rolling oil can cover the entire guide bar side guide plate 1. The specific operation is as follows:

[0016] 1. Install hot-rolled oil headers 3 along the edge 5 of the finish-rolled side guide plate on the downstream stand (generally F4-F7) of the finishing mill, and each header 3 is equipped with 5-6 hot-rolled oil nozzles 4 to ensure that the spraying range can be Cover the entire guide rule side guide 1. The nozzle 4 sprays to the inner surface of the side guide plate 1 through the circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com