Detection method and device of coke reactivity and post-reaction heat-treatability

A heat treatability and detection method technology, applied in the direction of measuring devices, electric devices, and thermometers using electric/magnetic elements that are directly sensitive to heat, can solve the problem of lack of characterization of bosh hearth coke thermal properties and excellent high temperature properties of coke Poor evaluation misleading, scarce strong caking coal unreasonable allocation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Examples of detection methods for coke reactivity and post-reaction heat treatability

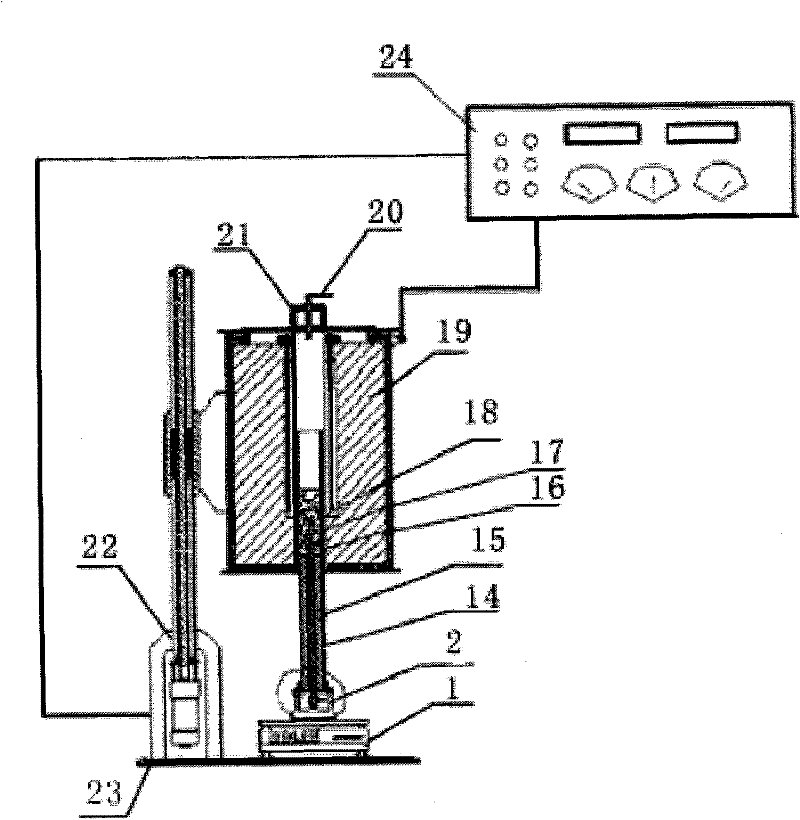

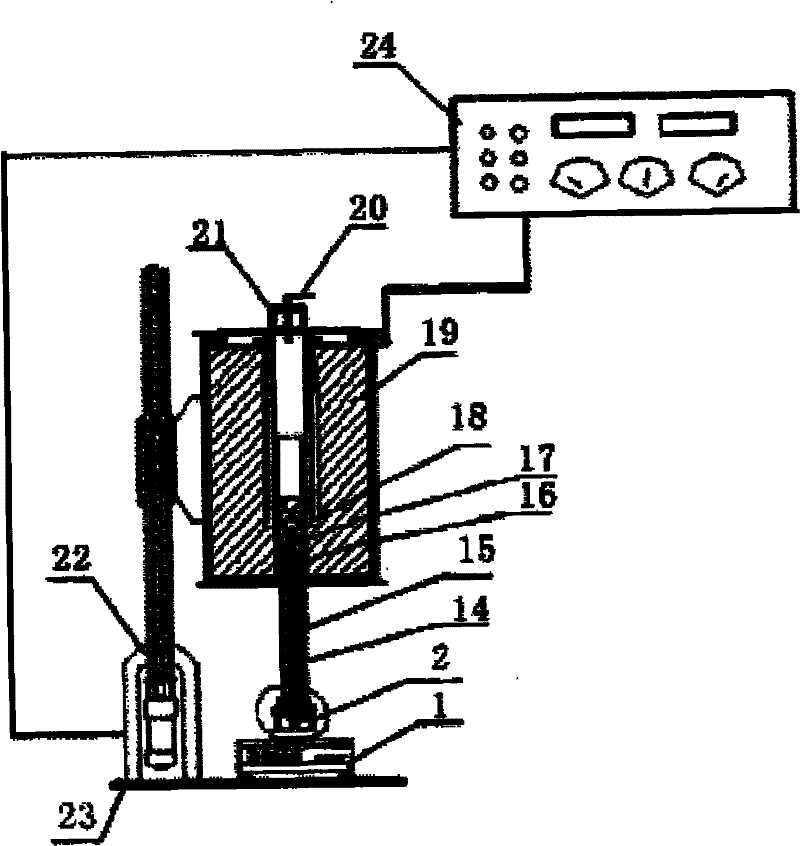

[0038] Such as figure 1 , figure 2 As shown, the coke reactivity provided by the present invention and the detection method of post-reaction heat treatability are specifically described as follows:

[0039] 1. Select and install the detection device

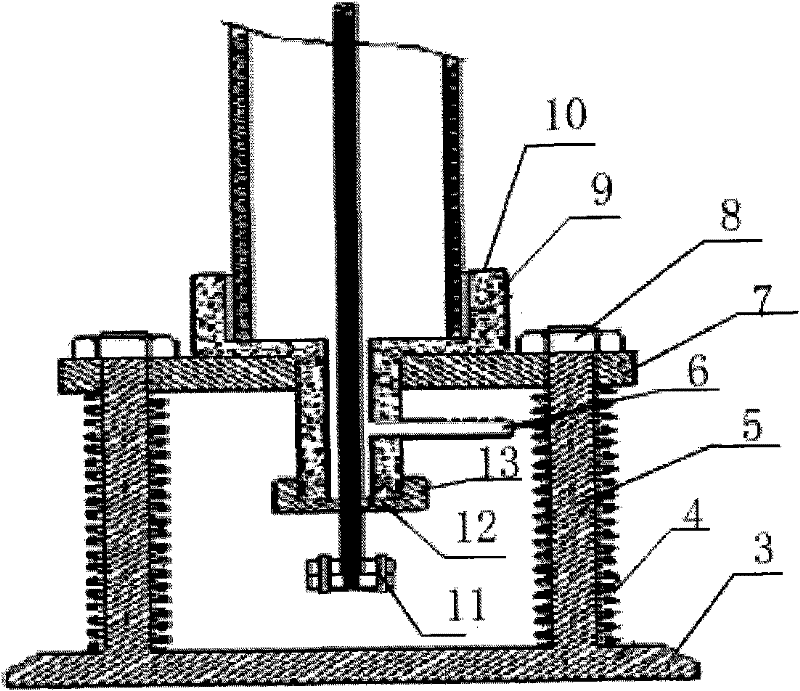

[0040] The maximum power is 12KW. The electric furnace is used as the heating furnace, and the maximum temperature of the heating furnace is 1600°C; the corundum tube is used as the reaction tube, and the size of the reaction tube is Φ80×1000mm; the electronic balance is used for weighing, and the maximum weighing weight of the electronic balance is 20kg, and the sensitivity is 0.10g. The lower part of the reaction tube (14) is inserted into the reaction tube sealing sleeve (10) on the reaction tube bracket (2), and the refractory packing (9) is used to seal the reaction tube (14) and the reaction tube sealing sleeve (10) . Air-pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com