Sludge fuel oil

A sludge and fuel technology, applied in the field of new fuels, can solve the problems of complex equipment, air pollution, and high investment, and achieve the effects of simplified production process, low environmental dust and noise, and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

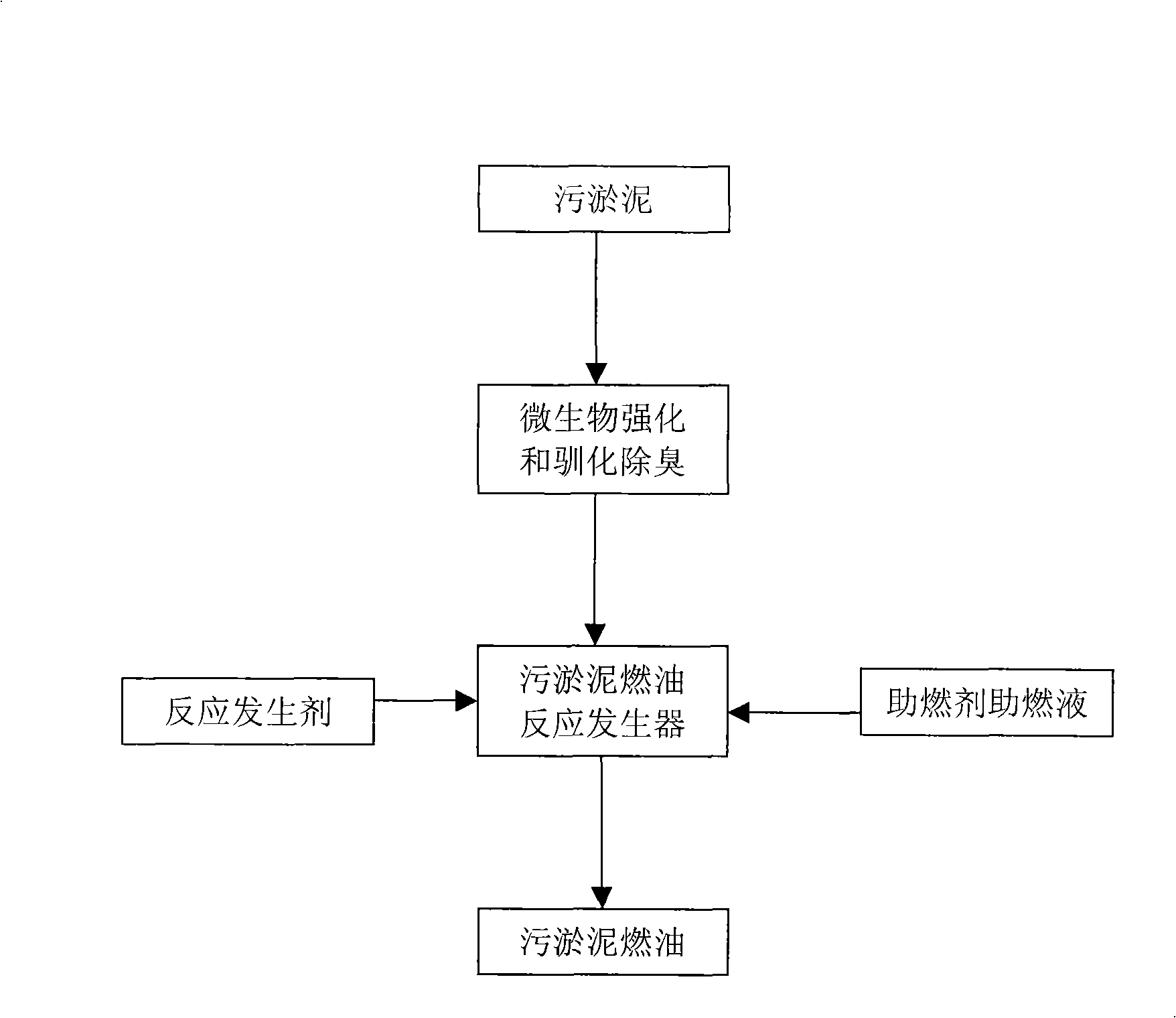

Method used

Image

Examples

Embodiment 1

[0073] Take Wenzhou Binhai Park Wastewater Treatment Plant as an example. The sludge in Wenzhou Sewage Treatment Plant mainly comes from industries such as leather, paper making, food, and biomedicine. It has a relatively high calorific value and has resource utilization value. For the convenience of explanation, hereinafter referred to as "Wenzhou sludge".

[0074] Table 1 Sludge Composition of Wenzhou Binhai Industrial Park Sewage Treatment Plant

[0075]

[0076] The calorific value of sludge decreases with the increase of moisture content, and the inverse ratio between the two shows a linear relationship.

[0077] Take the following raw materials: 100 kilograms of Wenzhou sludge, 2 kilograms of microbial deodorization strengthening training agent, 8 kilograms of combustion-supporting agent and combustion-supporting liquid, and 4 kilograms of reaction generator;

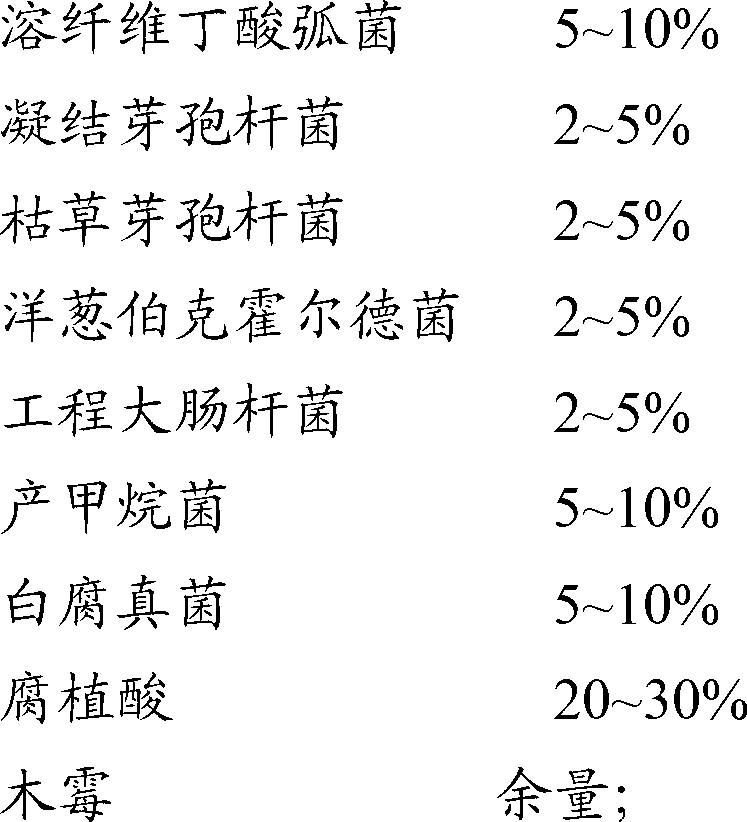

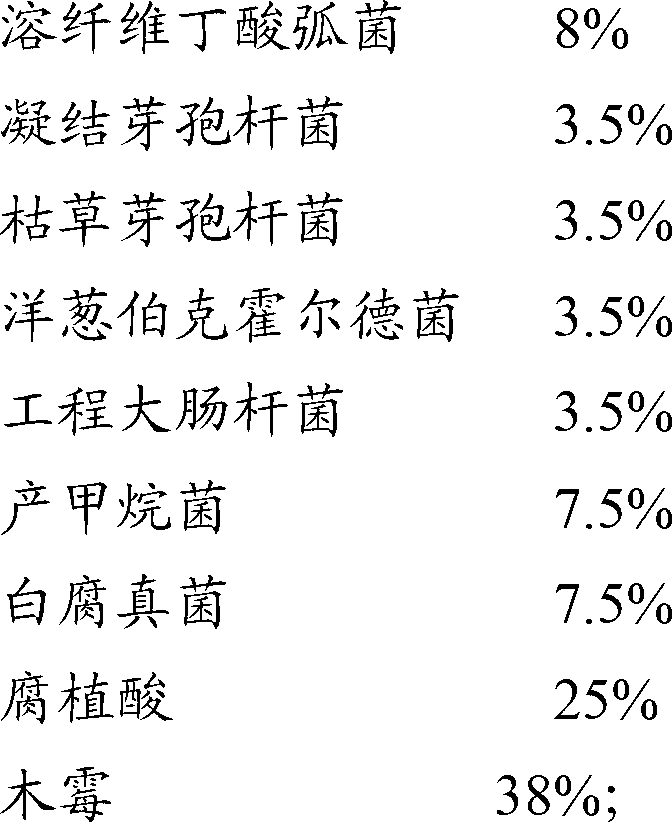

[0078] Described 2 kilograms of microbial deodorizing strengthening training agents, by weight percentage,...

Embodiment 2

[0102] Take the following raw materials: 100 kilograms of Wenzhou sludge, 2 kilograms of microbial deodorization strengthening training agent, 5 kilograms of combustion-supporting agent and combustion-supporting liquid, and 3 kilograms of reaction generator;

[0103] Described 2 kilograms of microbial deodorizing strengthening training agents, by weight percentage, are made up of following materials:

[0104] Butyrivibrio fibrisolvens 5%

[0105] Bacillus coagulans Hammer 5%

[0106] Bacillus subtilis 2%

[0107] Burkholderia Cepacia 5%

[0108] Engineered E. coli 2%

[0109] Methanogenium cariaci 10%

[0110] White rot fungi 5%

[0111] Humic Acid 30%

[0112] Trichoderma spp 36%.

[0113] Described 5 kilograms of combustion-supporting agent combustion-supporting liquids, by weight percentage, are made up of following materials:

[0114] Activated Charcoal 10%

[0115] Low temperature coal tar 40%

[0116] High quality coal 50%.

[0117] Described 3 kilograms of reac...

Embodiment 3

[0127] Take the following raw materials: 100 kilograms of Wenzhou sludge, 2 kilograms of microbial deodorization strengthening training agent, 5 kilograms of combustion-supporting agent and combustion-supporting liquid, and 4 kilograms of reaction generator;

[0128] Described 2 kilograms of microbial deodorizing strengthening training agents, by weight percentage, are made up of following materials:

[0129] Butyrivibrio fibrisolvens 10%

[0130] Bacillus coagulans Hammer 2%

[0131] Bacillus subtilis 5%

[0132] Burkholderia Cepacia 2%

[0133] Engineered E. coli 5%

[0134] Methanogenium cariaci 5%

[0135] White rot fungi 10%

[0136] Humic Acid 20%

[0137] Trichoderma spp 41%.

[0138] Described 5 kilograms of combustion-supporting agent combustion-supporting liquids, by weight percentage, are made up of following materials:

[0139] Activated charcoal 20%

[0140] Low temperature coal tar 30%

[0141] High quality coal 50%.

[0142] Described 4 kilograms of r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com