Winding device capable of improving service life of steel wire rope

A technology of hoisting device and wire rope, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of wear, severe, short service life of wire rope, etc., and achieve the effect of reducing use cost and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

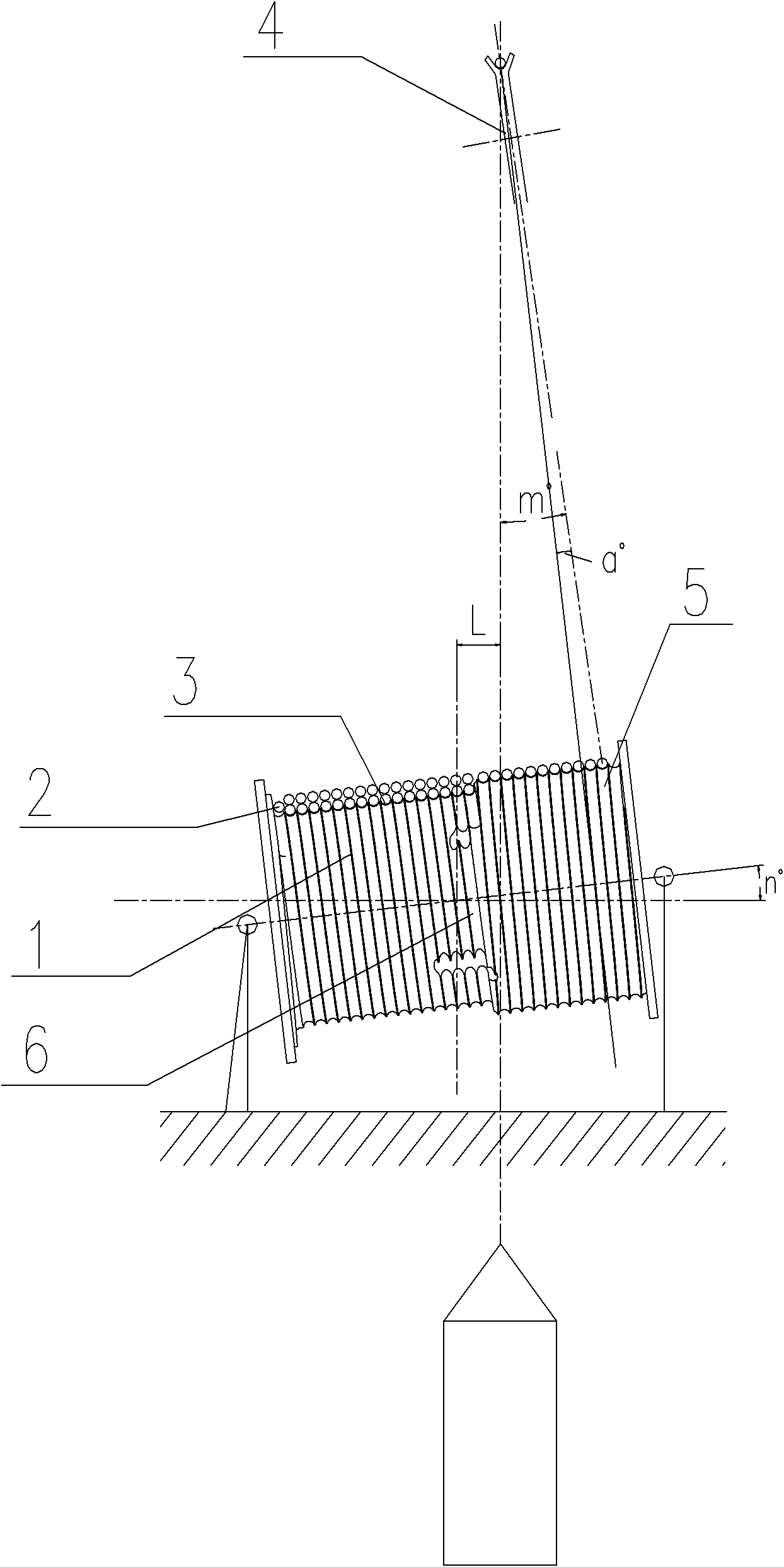

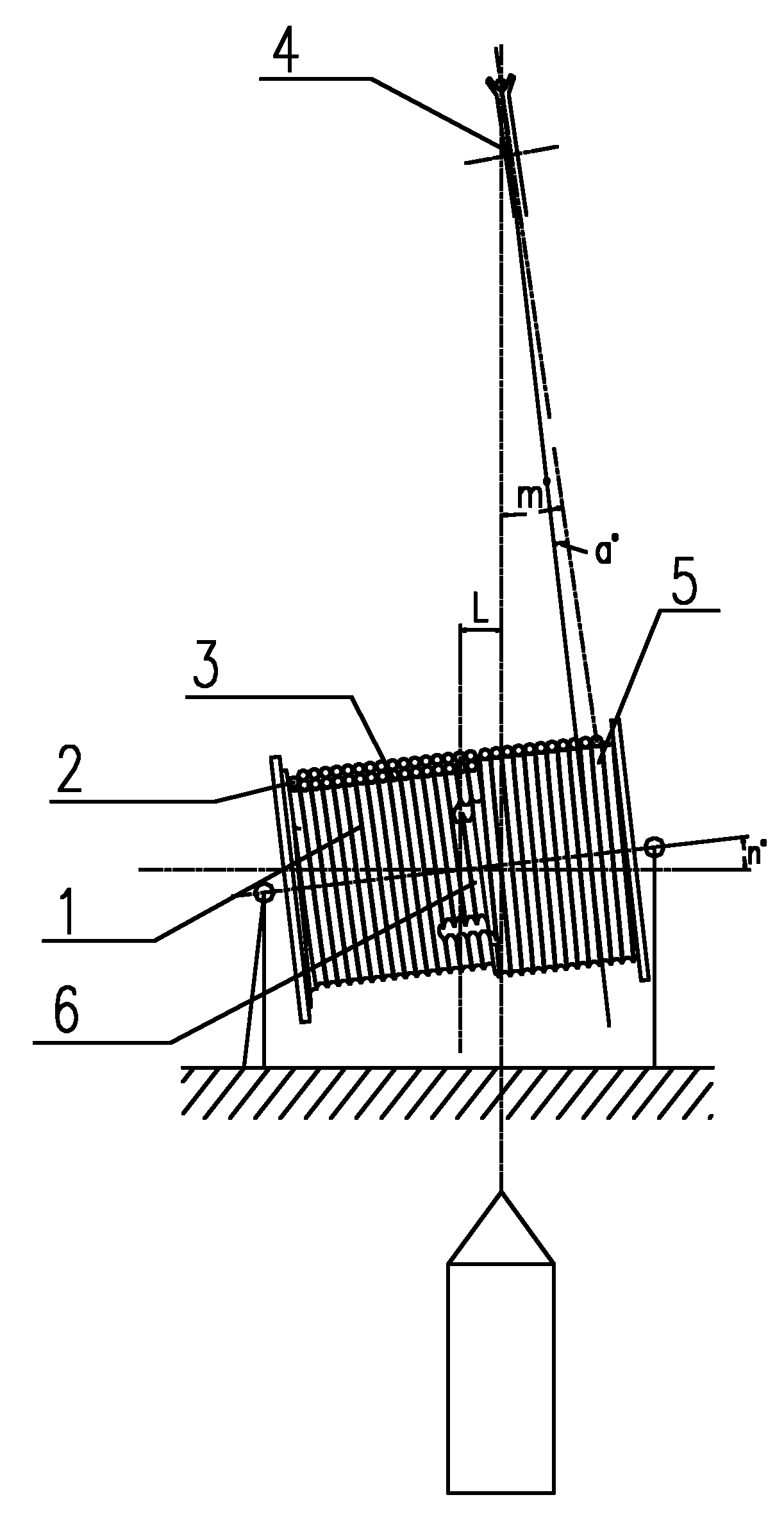

[0015] see figure 1 , the drum 1 is provided with an inner layer rope-carrying surface 3 and an outer layer rope-carrying surface 5, the radius of the outer layer rope-carrying surface 5 is greater than the radius of the inner layer rope-carrying surface 3, and the inner layer rope-carrying surface 3 and the outer layer rope-carrying surface The radius difference of the surface 5 is the distance between the two layers of steel wire ropes. The rope head of the steel wire rope 2 is fixed at the end rope head fixing point 6 at the end of the inner layer carrying rope 3 facing the end of the outer layer carrying rope surface 5, and the steel wire rope 2 is wound on the drum 1. When the orifice rope section of the steel wire rope 2 is on the outer layer rope-carrying surface 5, the axis of the drum 1 is installed obliquely with the horizontal plane,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com