Intelligent vibration monitor system

A vibration monitoring system, intelligent technology, applied to measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of large fluctuation range of vibration signal amplitude, indistinguishability, and inability to obtain key data, etc., to achieve high sensitivity and Effects of test accuracy, improvement of sensitivity and test accuracy, and simplified measurement operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and with the best embodiment.

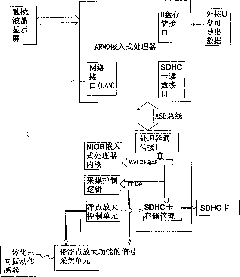

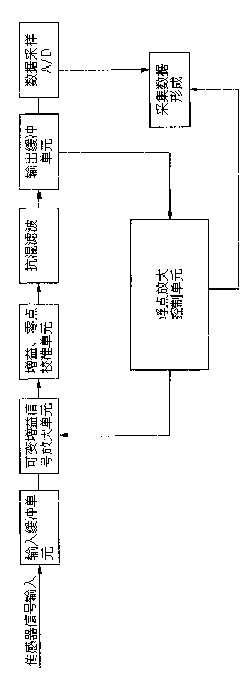

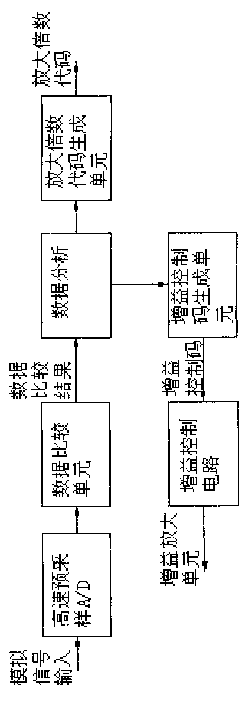

[0046] refer to figure 1 , first of all, the working principle of the whole instrument of the intelligent vibration monitoring system is explained: the vibration signal generated at the test site is picked up by the three-way sensor arranged on site, and converted into an electrical signal that can be collected by the vibrometer. The electrical signal passes through the signal acquisition unit of the vibrometer, and is converted into a digital signal recognizable by the computer under the control of the acquisition control logic. The signal acquisition unit is designed to realize the basic circuit of the floating-point amplification function. During this process, the floating-point amplification control logic compares and analyzes the signals, and continuously sends gain control codes to the signal acquisition unit, so that the signal acq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com