Contact positioning device of broad biaxially oriented film winder

A technology of biaxial stretching and positioning device, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of low reliability, inconvenient installation and maintenance, inaccurate positioning, etc., and achieve winding accuracy. Improve, reduce waste film, good film roll flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

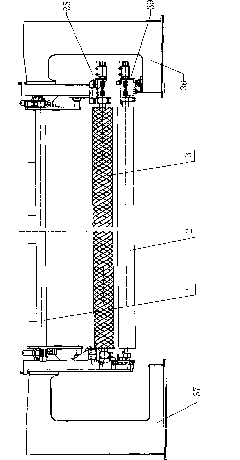

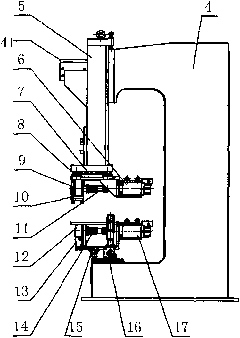

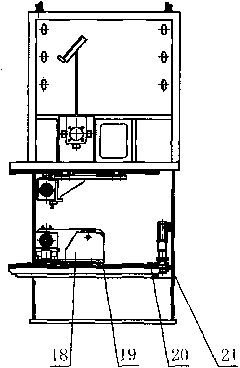

[0017] Attached below figure 1 to attach Figure 5 To further illustrate the present invention, the preferred embodiment of the present invention is: the contact positioning device of the wide-width biaxial stretch film winding machine described in this embodiment includes a left C-shaped support 23, a right C-shaped support 4, The driving part 36, the passive part 37, the film cutting mechanism 1, the tension roller 2, and the contact roller 3, wherein, the two ends of the film cutting mechanism 1 are respectively installed on the driving part 36 and the passive part 37 through the left and right film cutting machine bases 40 and 41. On the inner left and right wall panels 22,5. Both ends of the tension roller 2 and the contact roller 3 are respectively assembled on the left C-shaped frame 23 and the right C-shaped frame 4 through the driving part 36 and the passive part 37, and the contact roller 3 is located above the tension roller 2, and the film cutting mechanism 1 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com