Water band fastening device

A technology for fastening devices and hoses, applied in the direction of hose connection devices, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of large local stress, low efficiency, time-consuming and laborious, etc., to reduce time and work The effect of increasing the volume, increasing the area of action, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

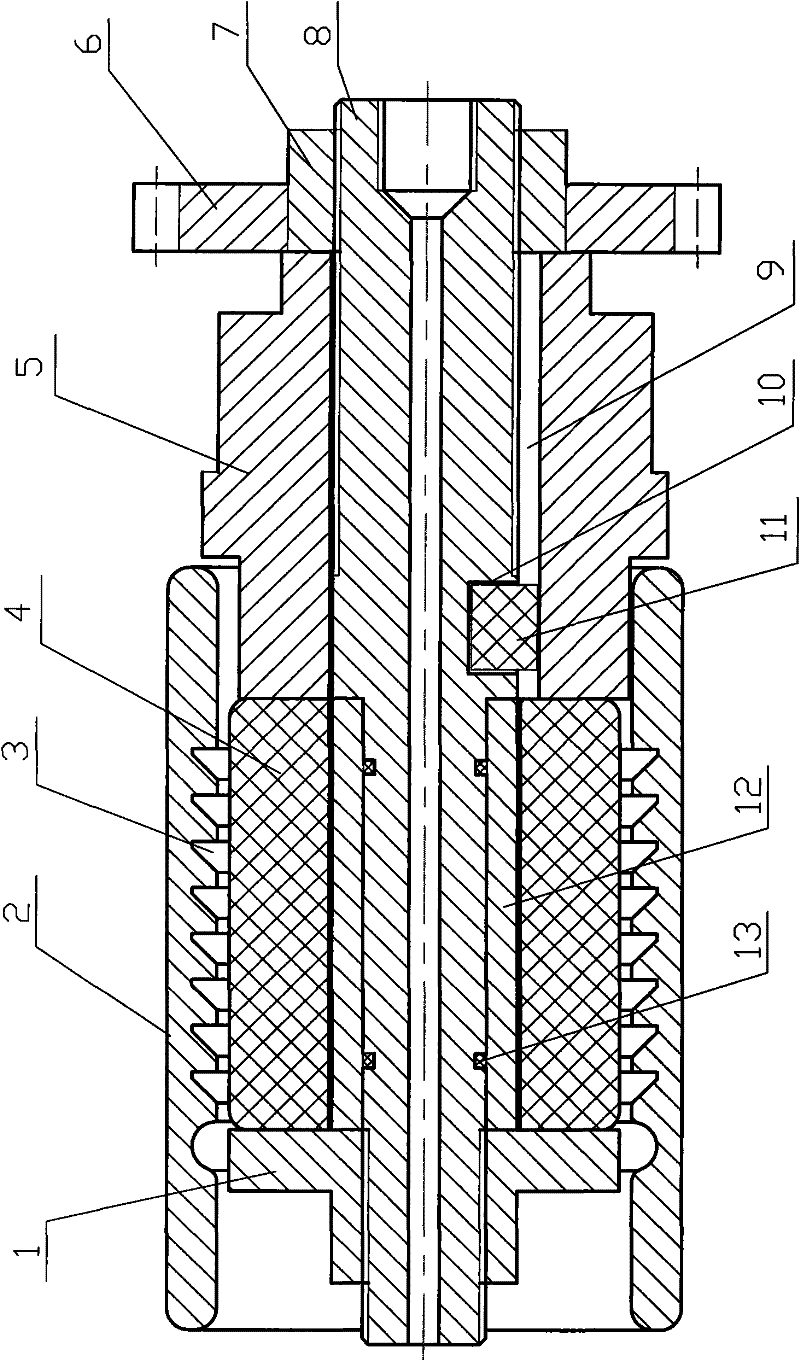

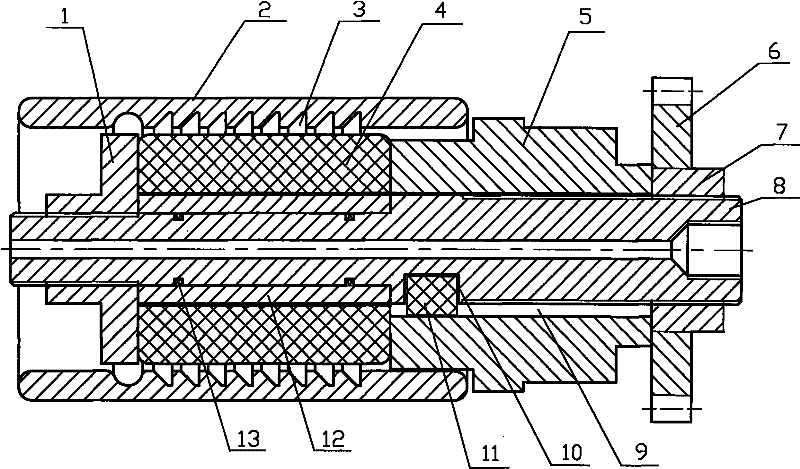

[0012] Refer to the attached figure 1 The hose fastening device of the present invention will be described in detail below.

[0013] The hose fastening device of the present invention has a structure comprising a main shaft 8, a fixed seat 5, a rubber clamping block 4, a plug 1, a transmission device and a jacket 2, and the main shaft 8 is provided with plugs in sequence from left to right 1. The rubber clamping block 4, the fixing seat 5 and the transmission device, the plug 1 is threadedly connected with the main shaft 8, the main shaft 8 is hollow inside, the plug 1, the rubber clamping block 4 and the fixing seat The outer side of 5 is provided with a jacket 2 , and the inner wall of the jacket 2 corresponding to the rubber clamping block 4 is provided with an annular depression 3 .

[0014] The transmission device includes a nut 7 and a gear 6, the gear 6 is arranged on the outside of the nut 7, and is fixedly connected with the nut 7, the right side of the main shaft 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com