Die casting machine and automatic judgment method of die casting quality

An automatic judgment and die-casting machine technology, which is applied in the field of automatic judgment of the quality of die-casting machines and die-casting workpieces, can solve the problems of large batches of defective products, complicated structures, and cannot reflect the quality of die-casting workpieces, so as to improve production efficiency and product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

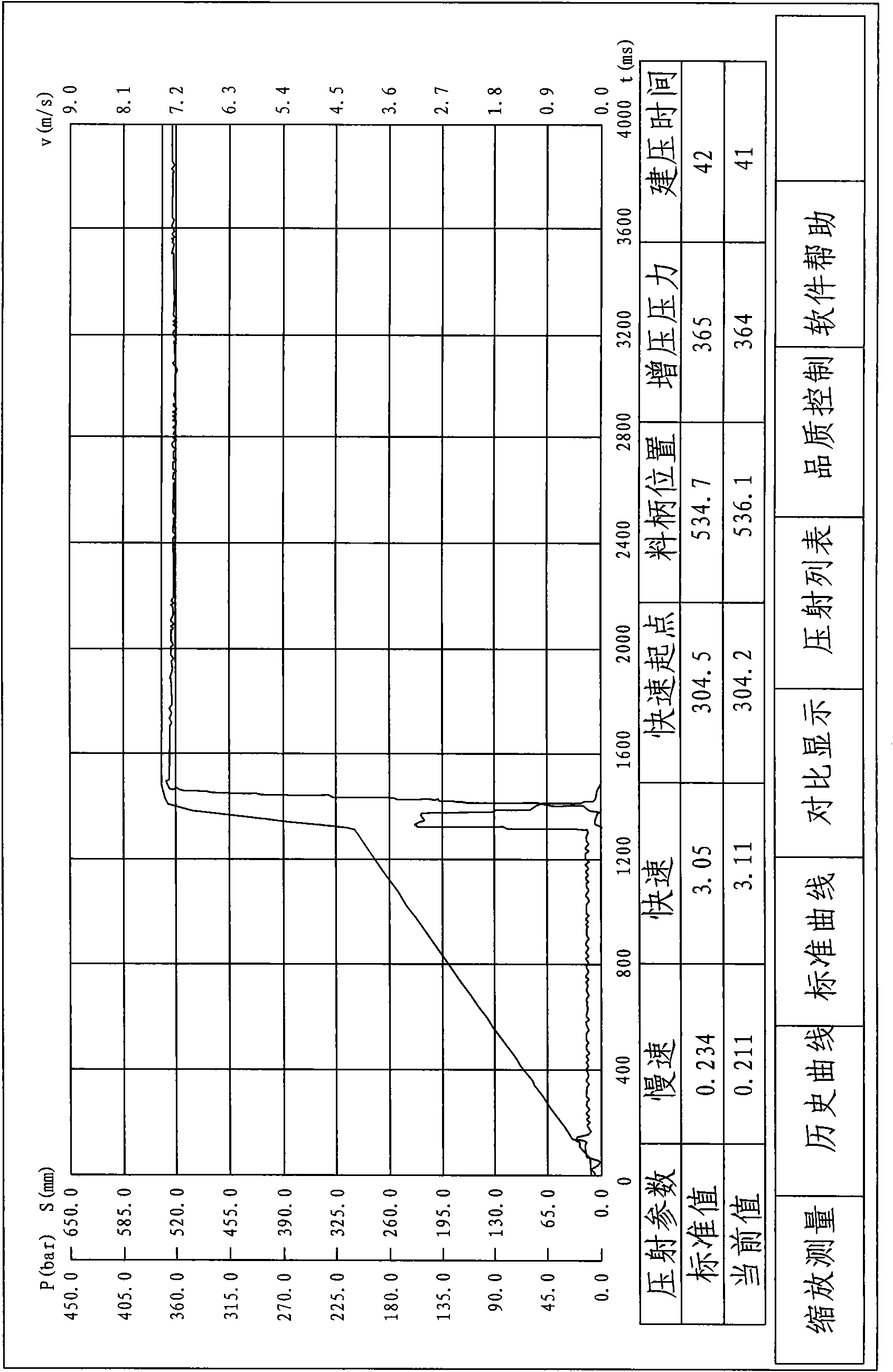

[0019] see Figure 1-Figure 2 , the die-casting machine includes an injection cylinder provided with a pressure sensor and an injection position detection read head, the pressure sensor and the injection position detection read head are connected to a profiler; the profiler is electrically connected to an alarm device and a display screen, as shown in the figure not shown.

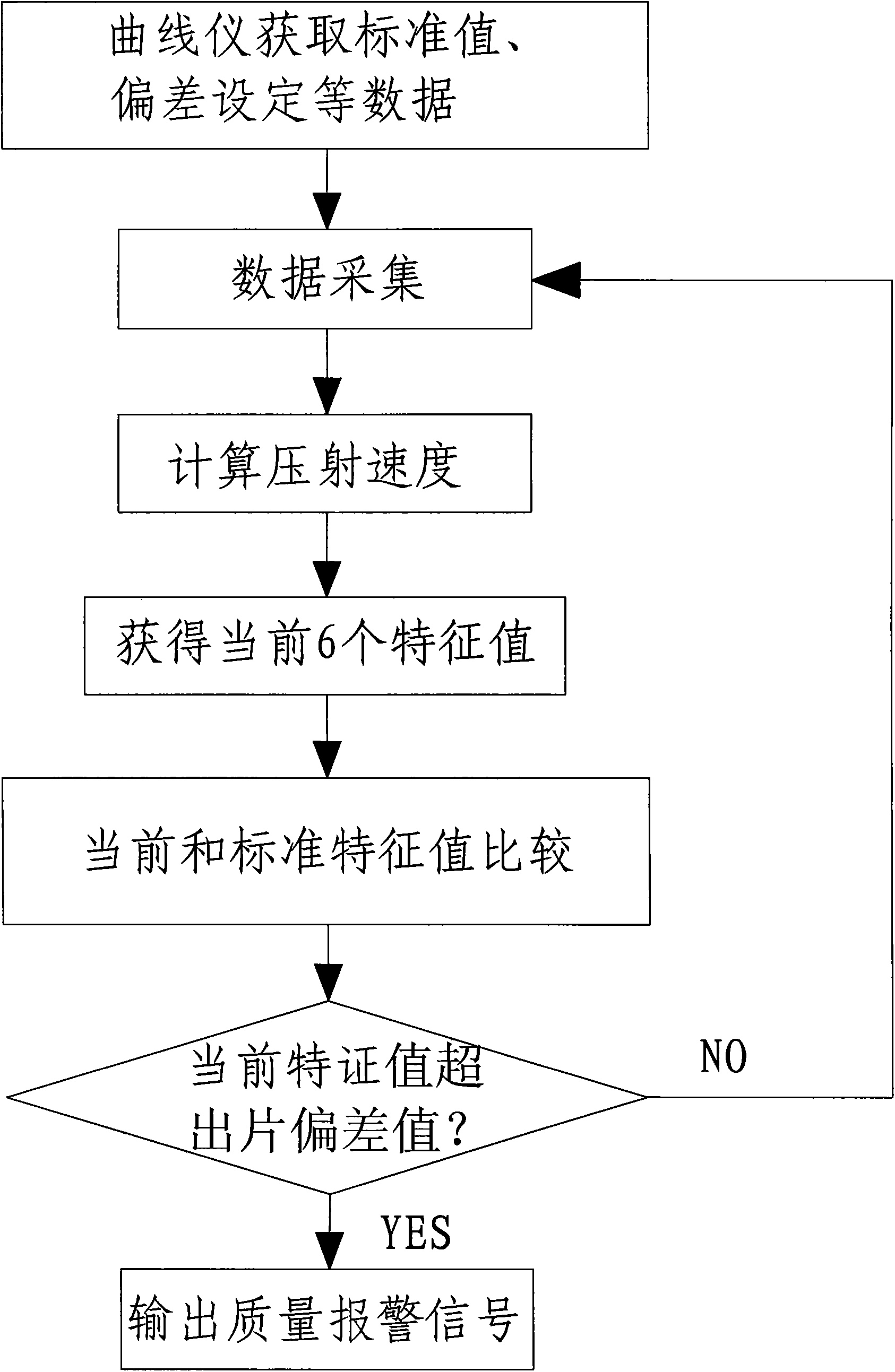

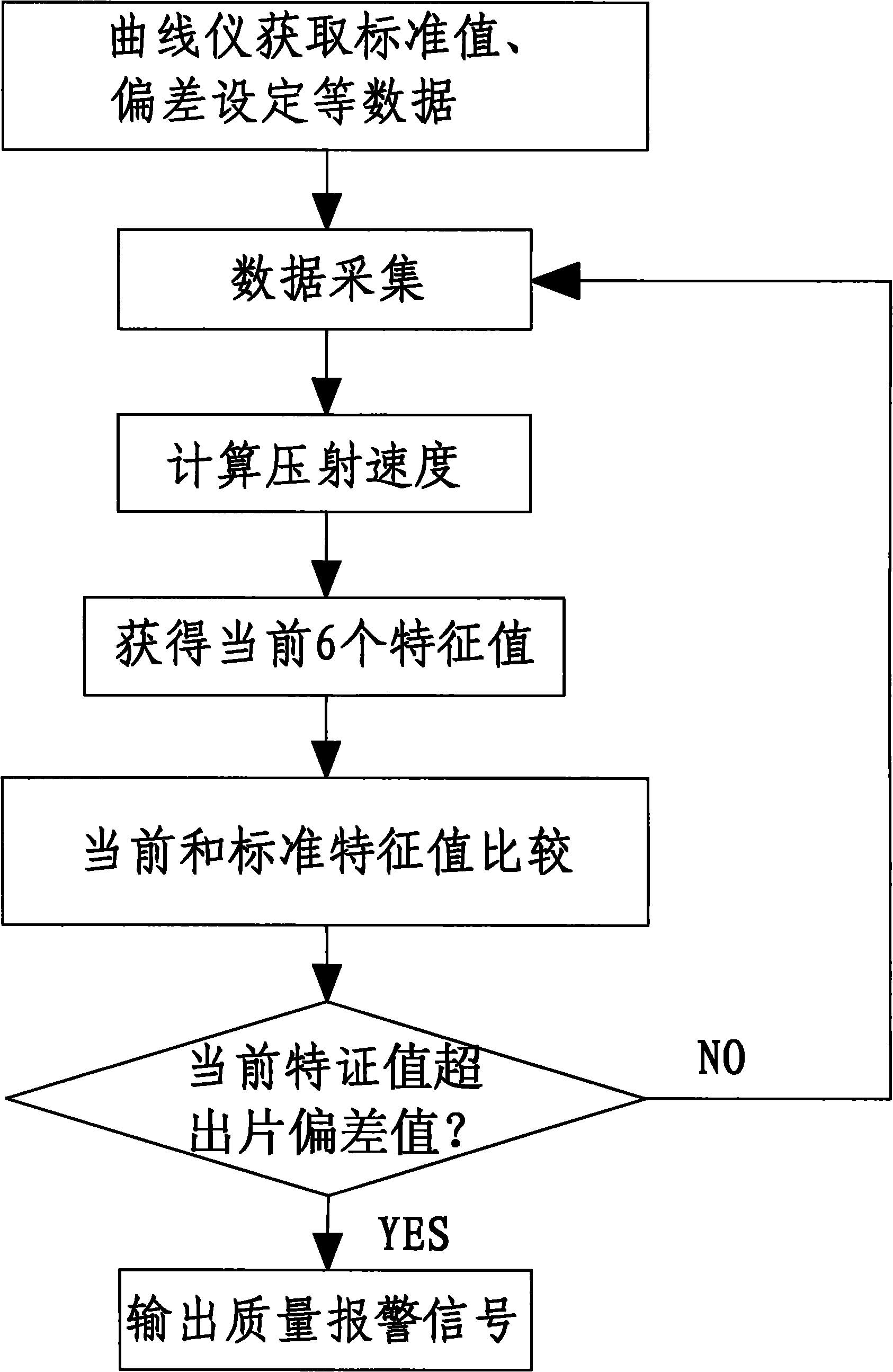

[0020] The automatic judgment method of the quality of die-casting workpieces. The injection process of the die-casting machine includes six characteristic values: slow injection speed, fast injection speed, slow speed to fast position, maximum speed, maximum pressure, and pressurization establishment time. , which detects the current data of six characteristic values including the following steps: first step, setting the curve meter to obtain sampling time, standard value of cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com