Electronic pulsator with low power consumption

A pulsator, low power consumption technology, applied in the field of pulsator, can solve the problems of poor reliability and high operation and management cost, and achieve the effect of reducing line loss, increasing protection function, and not easy to damage the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

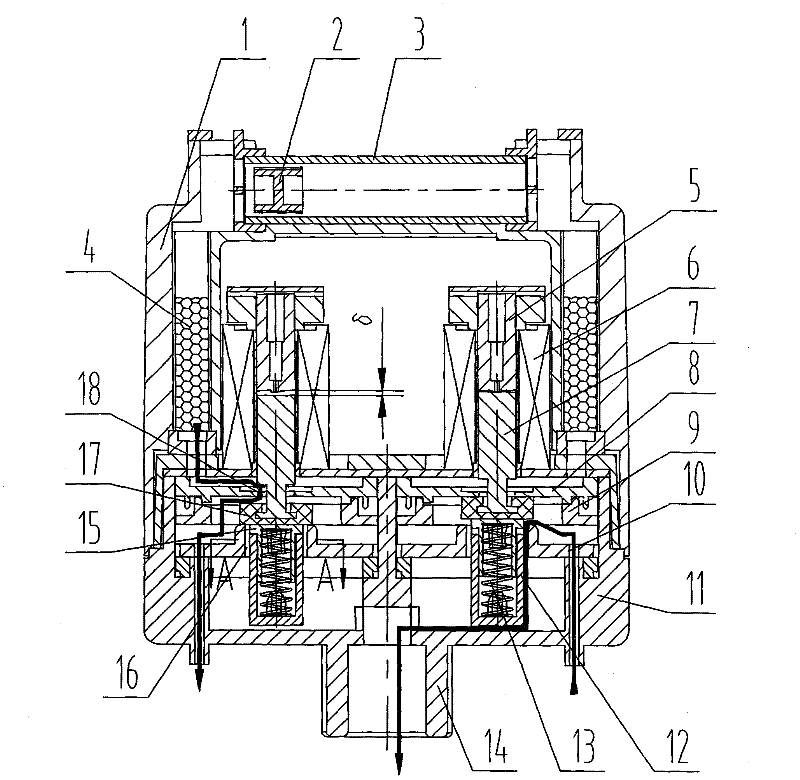

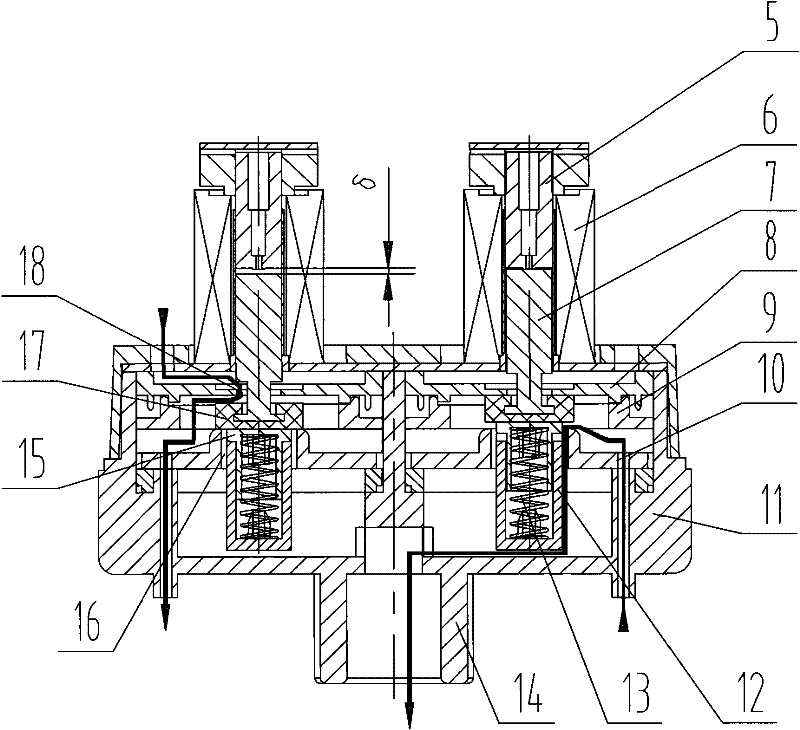

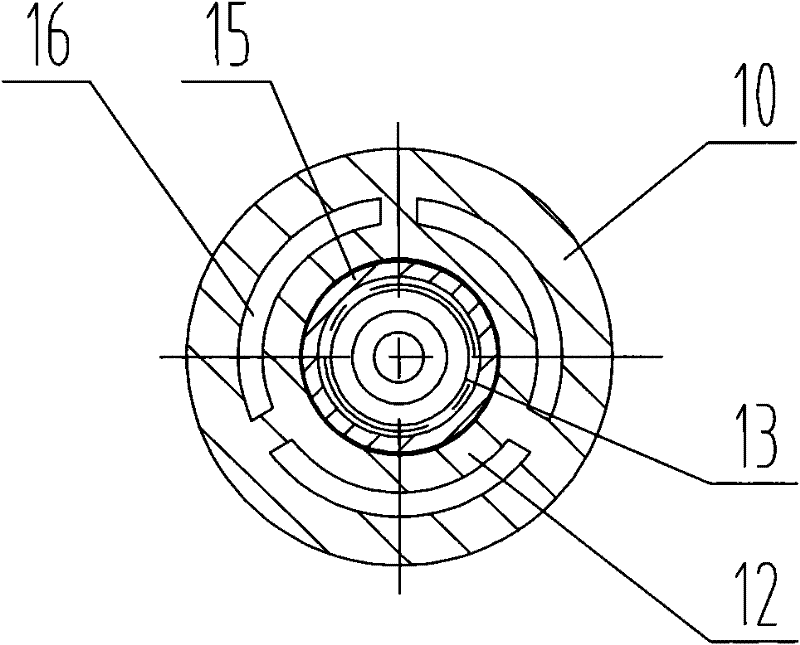

[0016] The structure of the low power consumption electronic pulsator of the present invention is as follows: figure 1 As shown, it includes the outer casing 1, the air filter sponge 4 filled in the inner cavity of the outer casing 1, the pulsator body 11, the vacuum pipe 14 arranged at the bottom of the pulsator body 11, and the lower chamber installed in the pulsator body 11 in sequence Body 10, upper cavity 9, cavity loam cake 8, two fixed iron cores 5, coil 6, moving iron core 7 sets, two moving iron cores 7 respectively pass through two atmospheres on the cavity loam cake 8 Passage 18 extends into the chamber that is formed by lower chamber 10 and upper chamber 9, and a valve body 17 is respectively installed at its end, and two valve bodies 17 are respectively connected with two vacuum passages 16 that are positioned at lower chamber 10. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap