Screwing and buckling clamp for connecting and disassembling drill rod and sleeve pipe

A technology of turnbuckle pliers and casing, which is applied in the direction of drill pipe, drill pipe, casing, etc., which can solve the problems of high labor intensity, low labor efficiency, and the trouble of screwing and fastening the two pipes in alignment, so as to reduce labor costs. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

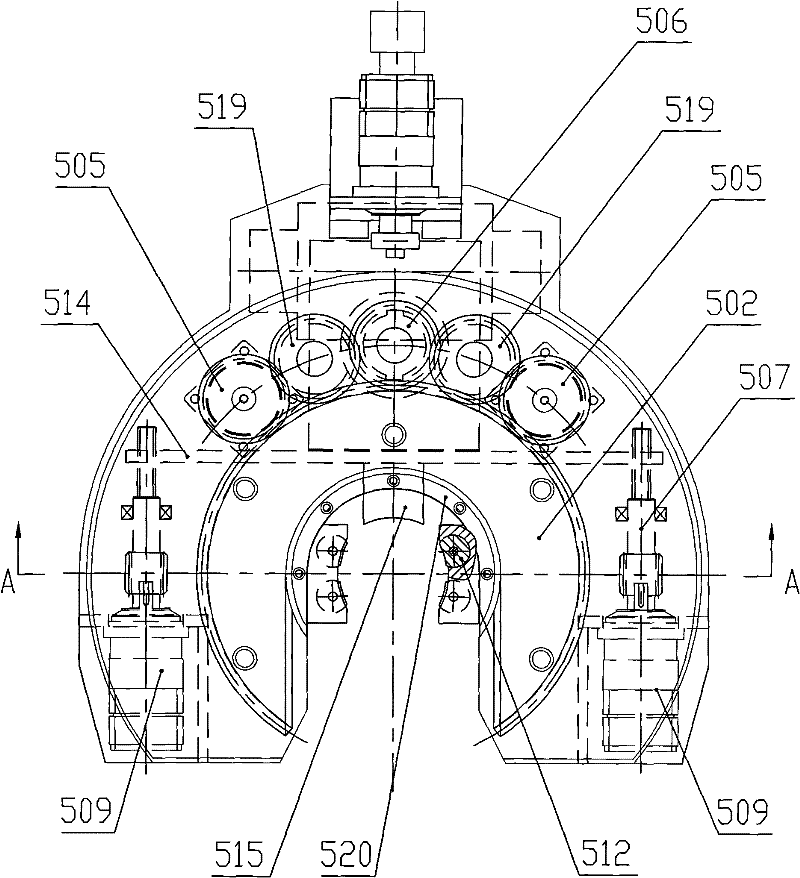

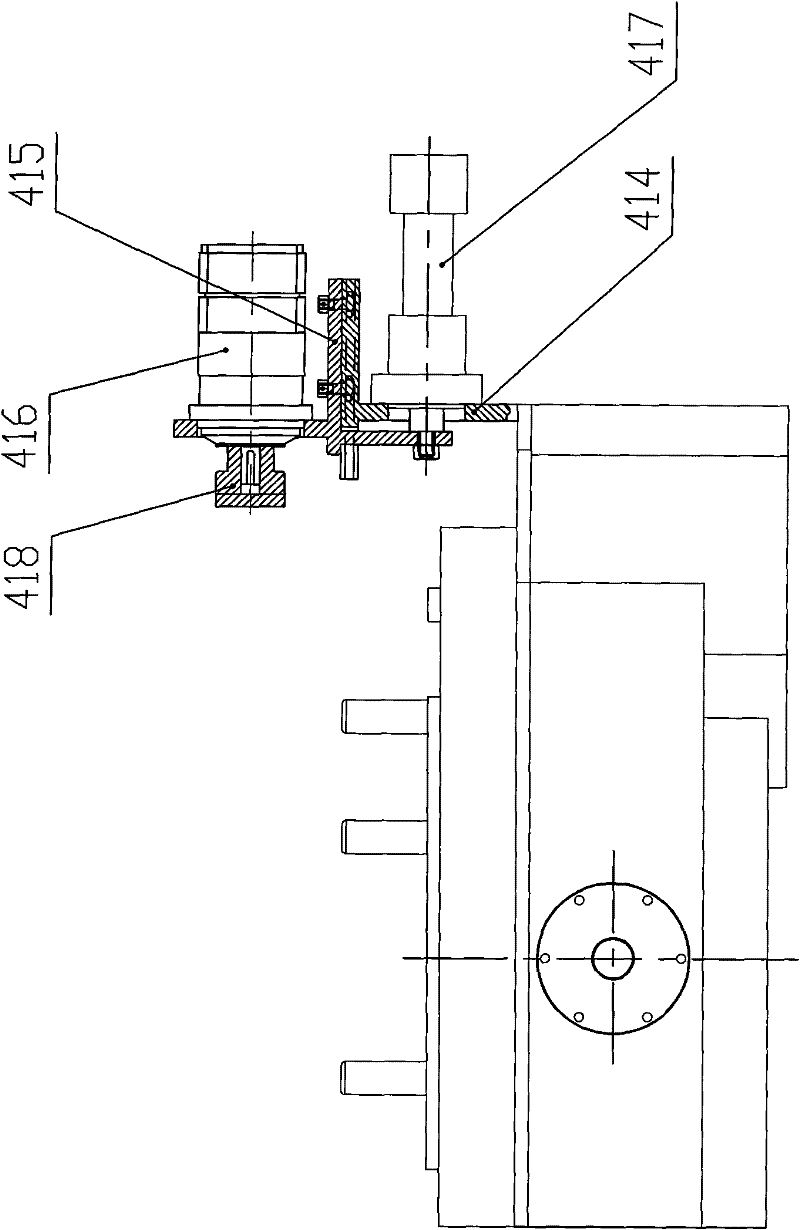

[0028] Such as figure 1 , 2 , 4 and 5: the fixed pliers include a fixed pliers housing 501, a large ring gear 502 with an opening and a large ring gear seat 503, and the large ring gear seat 503 is arranged above the fixed pliers housing 501 On the support plate 504 of the large ring gear 502, the lower part of the large ring gear 502 has an annular groove, and the upper surface is provided with a positioning pin 513, through which the large ring gear 502 is set on the large ring gear seat 503 and the large ring gear 502 can rotate relative to the large ring gear seat 503; the large ring gear driving gear 505 and the fastening gear 506 are also arranged on the support plate 504, and the large ring gear driving gear 505 and the fastening gear 506 are connected with an independent oil motor and The large ring gear driving gear 505, the fastening gear 506 and the outer ring of the large ring gear 502 mesh in pairs; the fixed pliers housing 501 below the support plate 504 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com