Cutting tool for boring inner hole groove

A groove and boring technology, applied in the direction of tools, boring heads, turning equipment, etc. for lathes, can solve the problems of affecting processing quality, inability to process, low production efficiency, etc., to eliminate the alignment error of secondary card loading , The effect of high machining accuracy and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

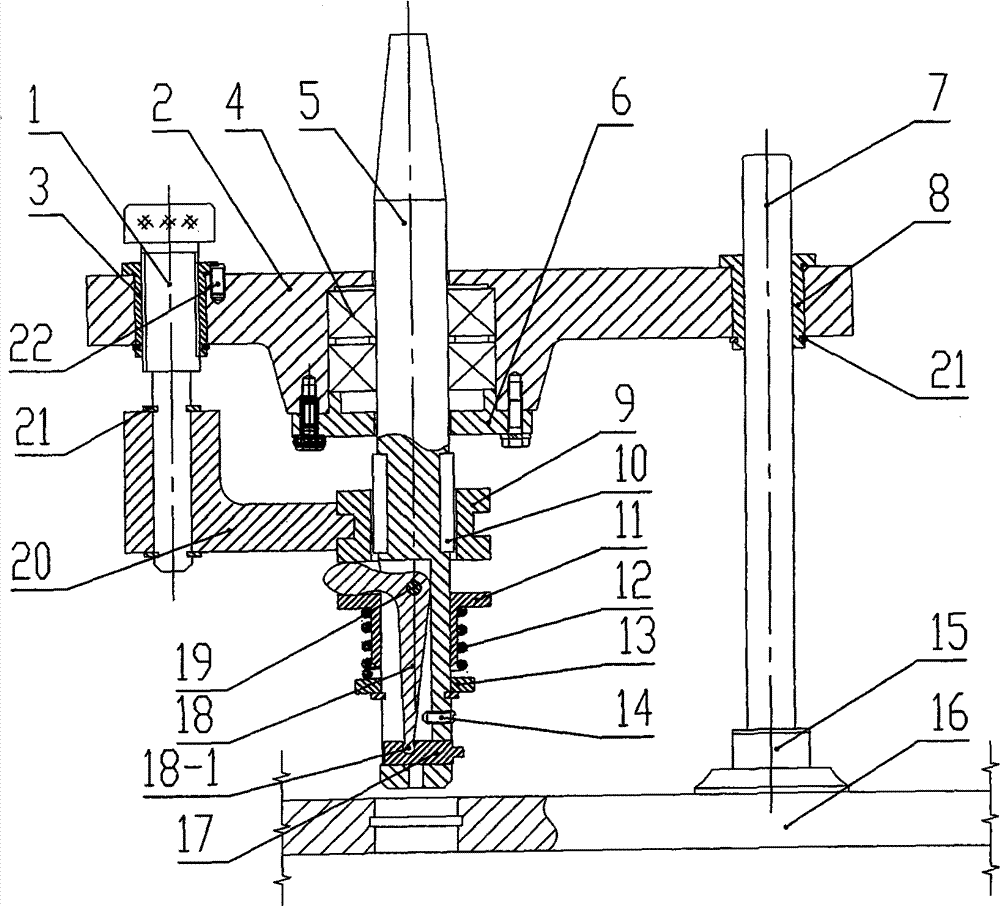

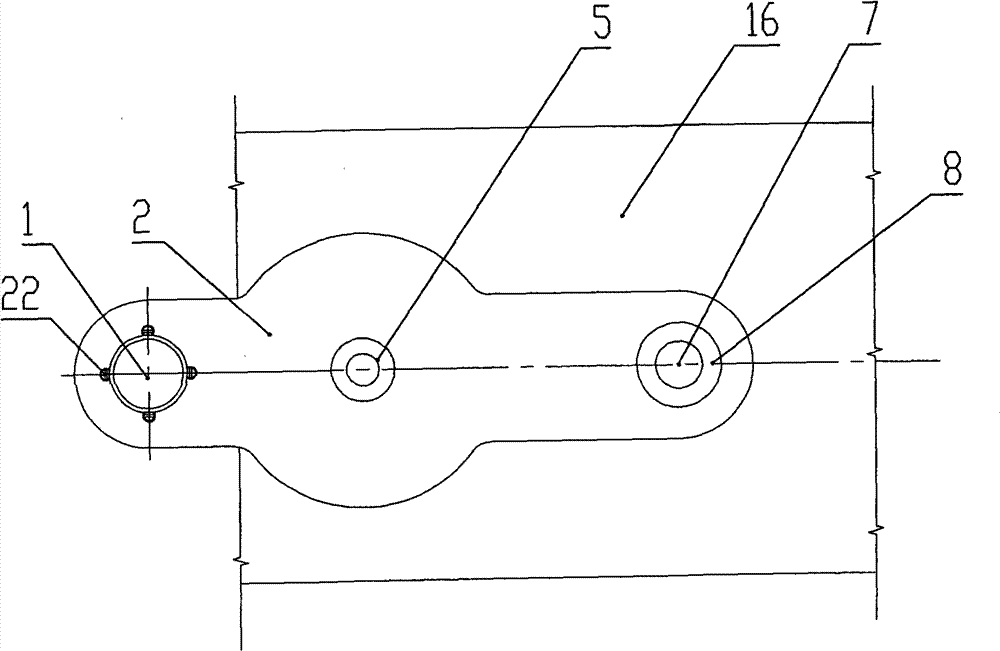

[0016] like figure 1 , figure 2 Shown: an inner hole groove boring tool, including a tool shank 5 and a tool head 17 installed on the tool shank; it is characterized in that: the described tool head 17 is slidably fitted in a square hole inserted at the end of the tool shank In the middle, the upper end of the cutter head 17 is connected with the lower end of the feed fork 18, and the feed fork 18 moves the cutter head 17 along the axial movement of the cutter bar 5 to realize the boring of the inner hole groove; the feed fork 18 The upper end of the feed fork 18 is close to the lower end surface of the sliding sleeve 9 through the hinge shaft 19 and the knife rod 5 is hinged; The upper and lower ends are installed on the lower end of the screw rod 1 through the spring clip 21, the screw rod 1 is connected with the fixing seat 2 through the nut 3, and the fixing seat 2 is installed on the upper part of the cutter bar 5 through the bearing 4 and the bearing cover 6; A spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com