Coating zone with inclined guide rails

A coating and area technology, applied in the direction of spray device, spray booth, etc., can solve the problems of difficult to obtain guide rails, and the paint booth cannot be too wide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

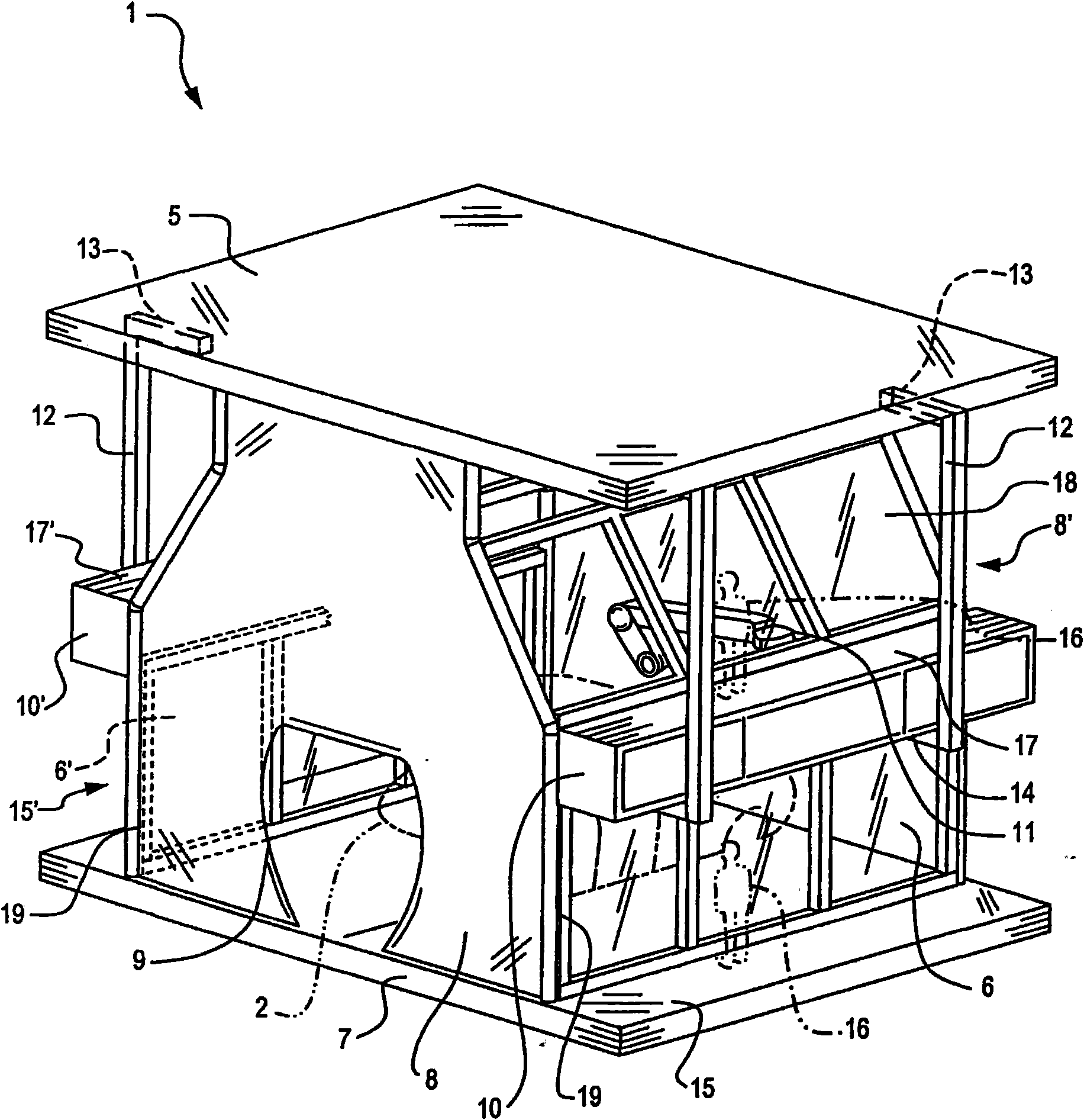

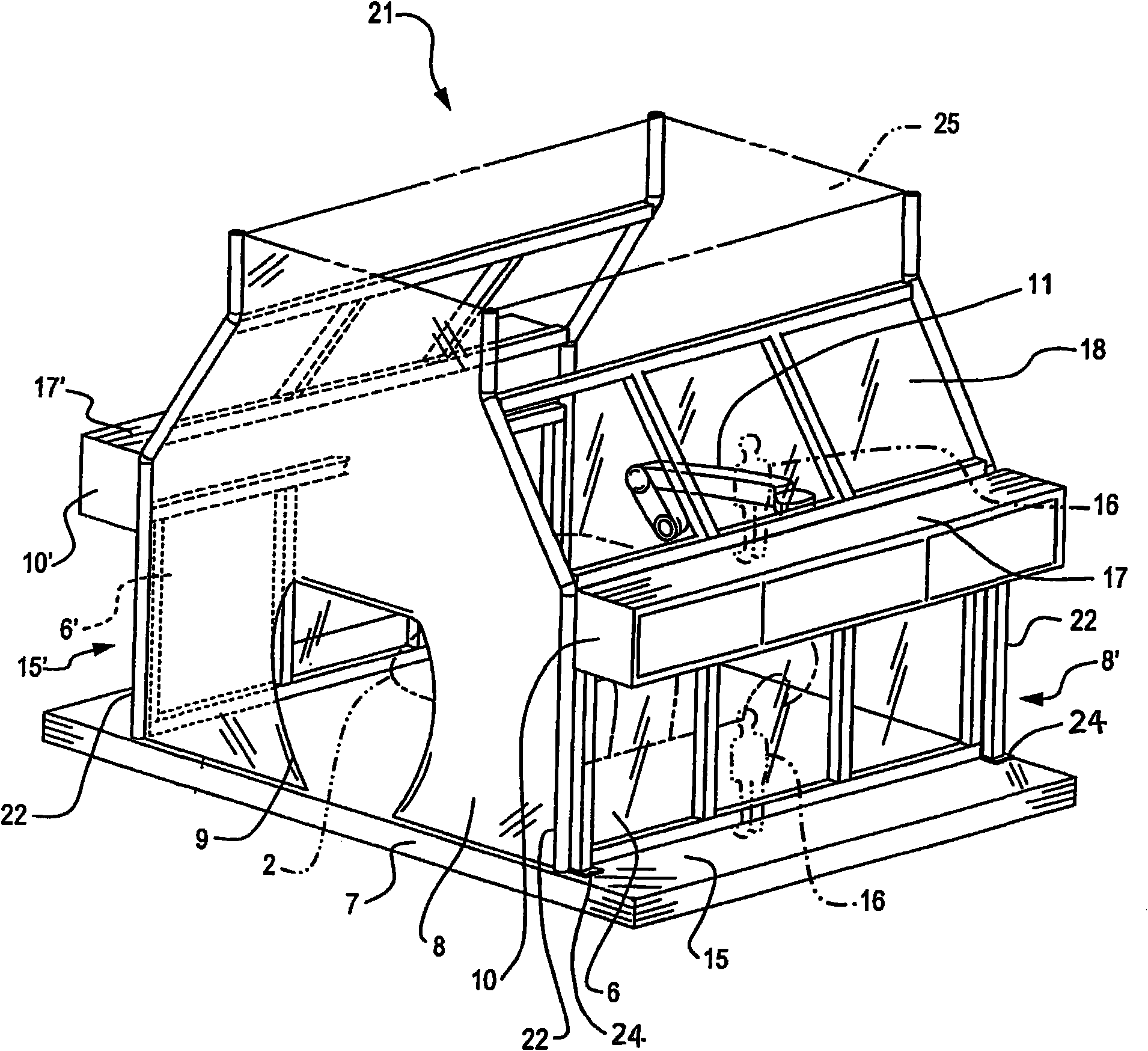

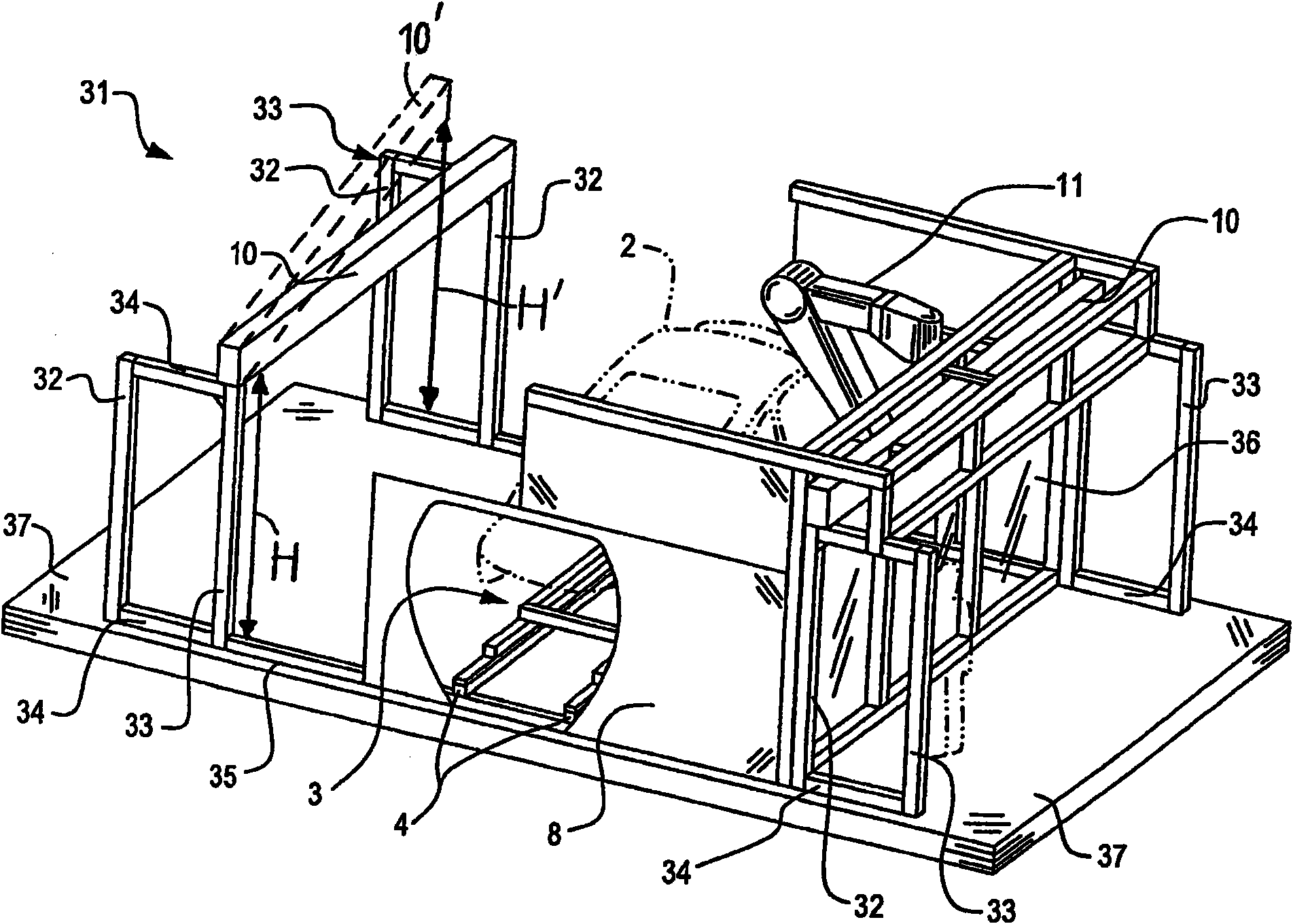

[0031] figure 1 The painting area 1 for the body 2 shown in can form part of a paint booth. However, the painting area described here and below can also be arranged inside a wider painting booth. Can be used on conventional floor conveyors 3 (cf. image 3 , figure 1 Not shown in) the upper edge, for example, consists of guide rail 4 ( image 3 ) conveys the vehicle body through the coating area 1 through the conveying path defined by . The coating area is bounded at the top by a horizontal top plate 5, on both sides by side walls 6 or 6' arranged parallel to the conveying path, at the bottom by a horizontal floor 7 and at the inlet and / or outlet ends by The partition walls 8 and 8' are bounded. Furthermore, similar or different coating areas can be arranged successively along the conveying path, for example in the same coating booth outside the partition walls 8 and / or 8'. In a conventional manner known per se, in operation, a substantially vertically downwardly directed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com