Blue-ray disc die assembly

A technology of a stamping device and a Blu-ray disc, which is applied in the directions of optical record carriers, optical record carrier manufacturing, recording/reproducing by optical methods, etc. Parallel contact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

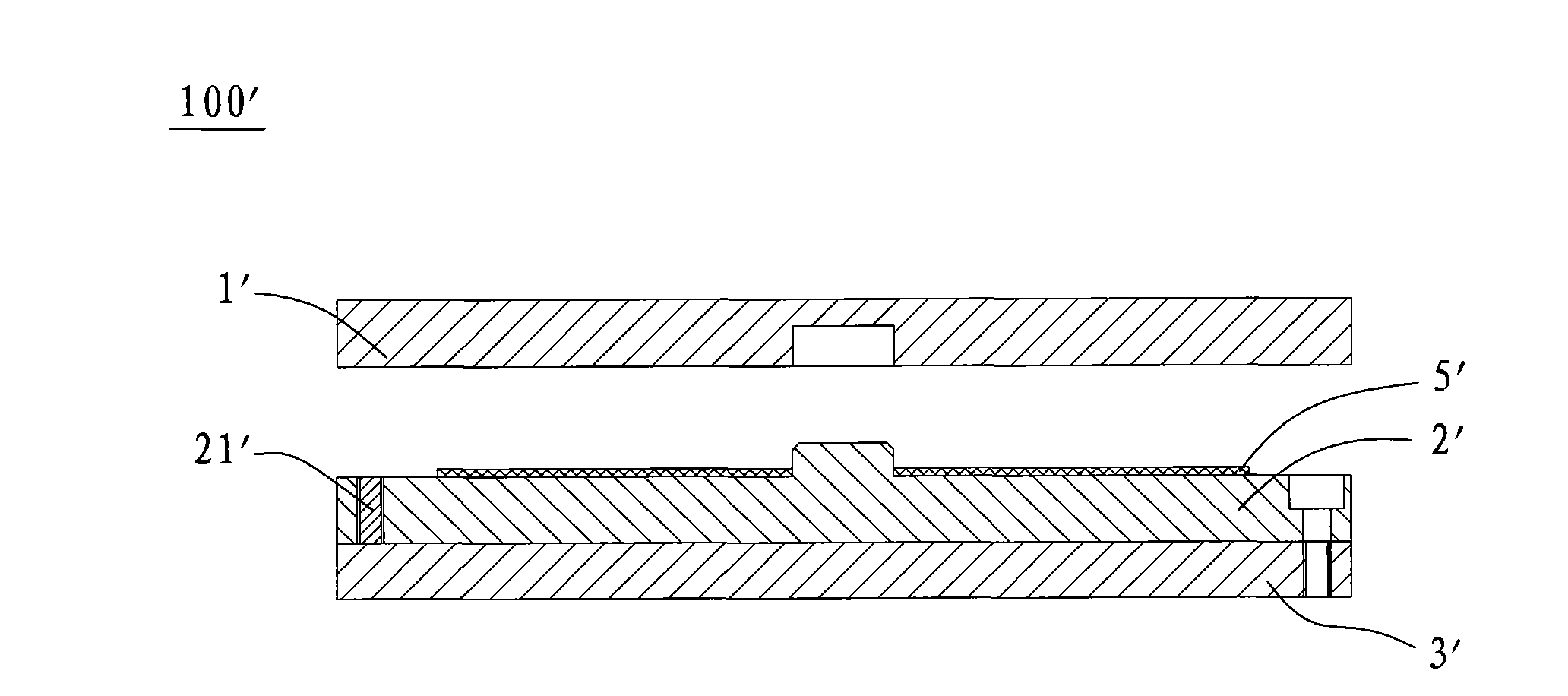

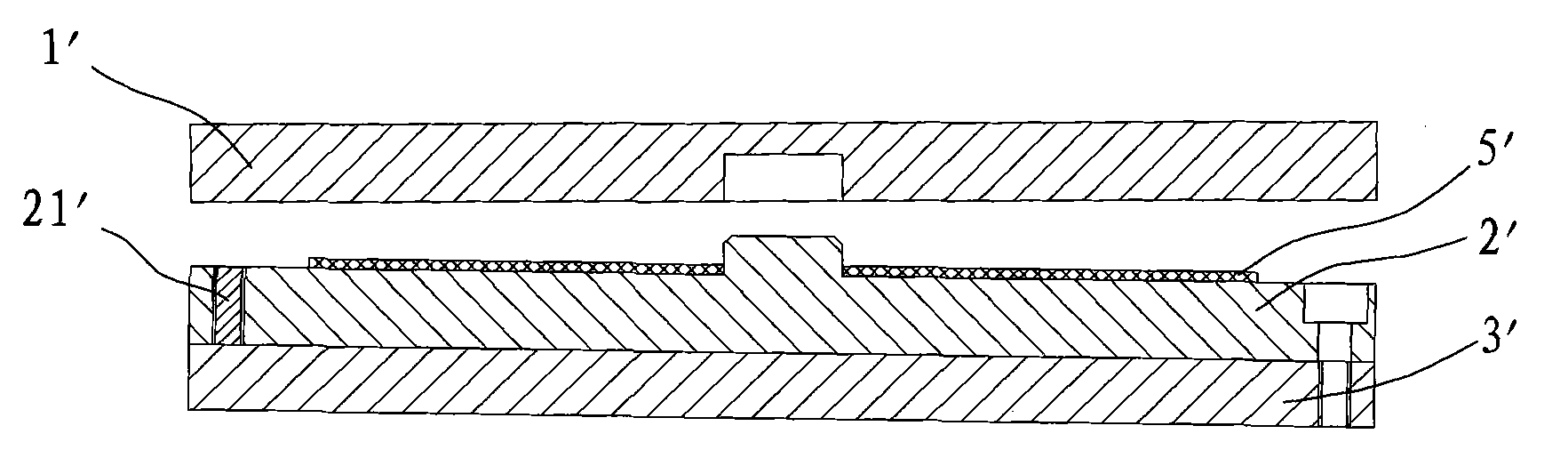

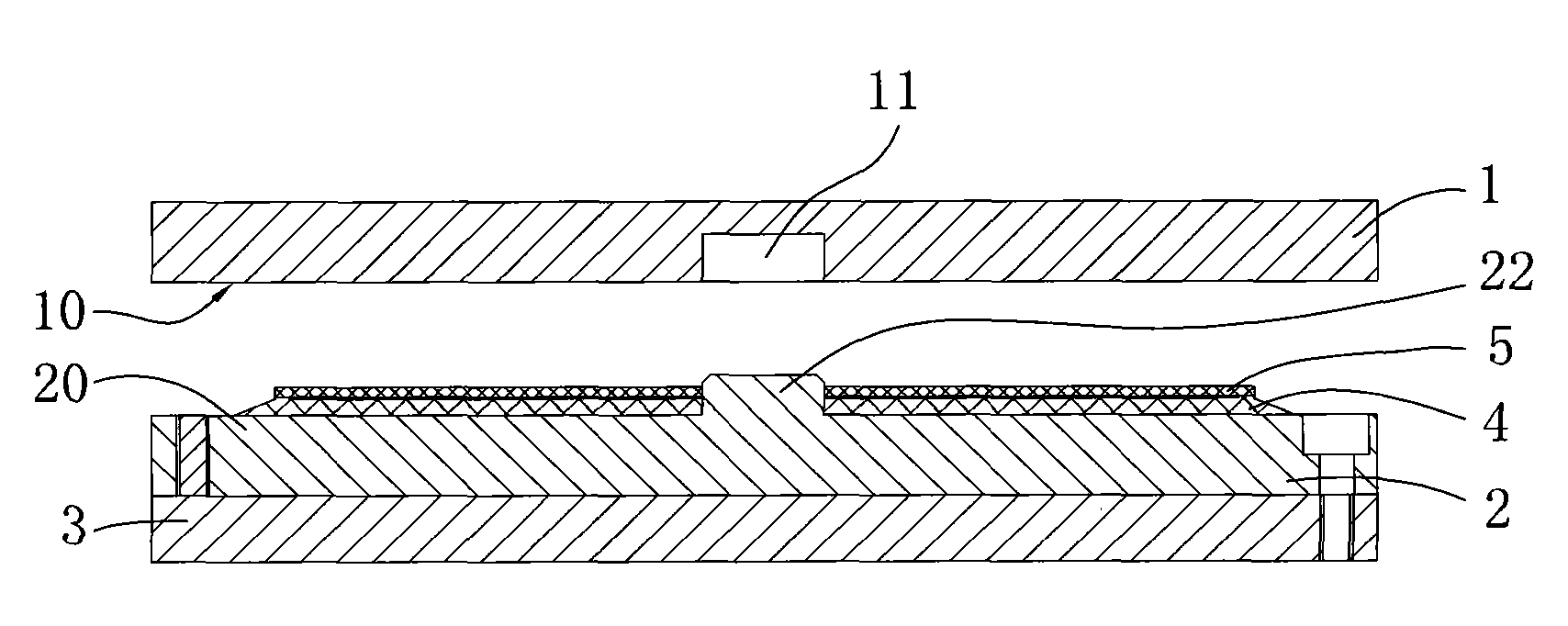

[0020] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, such as Figure 3-5 As shown, the Blu-ray disc molding device 100 provided by the present invention includes a mounting base 3, a lower template 2 and an upper template 1, the mounting base 3 has a horizontal mounting surface (not shown in the figure), and the lower template 2 Installed on the installation surface, the lower template 2 has a flat lower pressing surface 20, the upper template 1 has a flat upper pressing surface 10 opposite to the lower pressing surface 20, the lower A positioning column 22 protrudes from the center of the pressing surface 20, and the upper pressing surface 10 is inwardly recessed against the positioning column 22 to form a positioning hole 11, wherein an elastic circular gasket is also included. 4. An installation hole 42 is opened at the center of the gasket, and the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com