Filling controller of hazardous chemical gas cylinder

A technology for hazardous chemical gas cylinders and controllers, which is applied in container filling methods, gas/liquid distribution and storage, and container discharge methods, etc., can solve the problems of troublesome supervision, poor supervision accuracy, and low supervision work efficiency. The effect of convenient supervision, good supervision accuracy, and high supervision work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

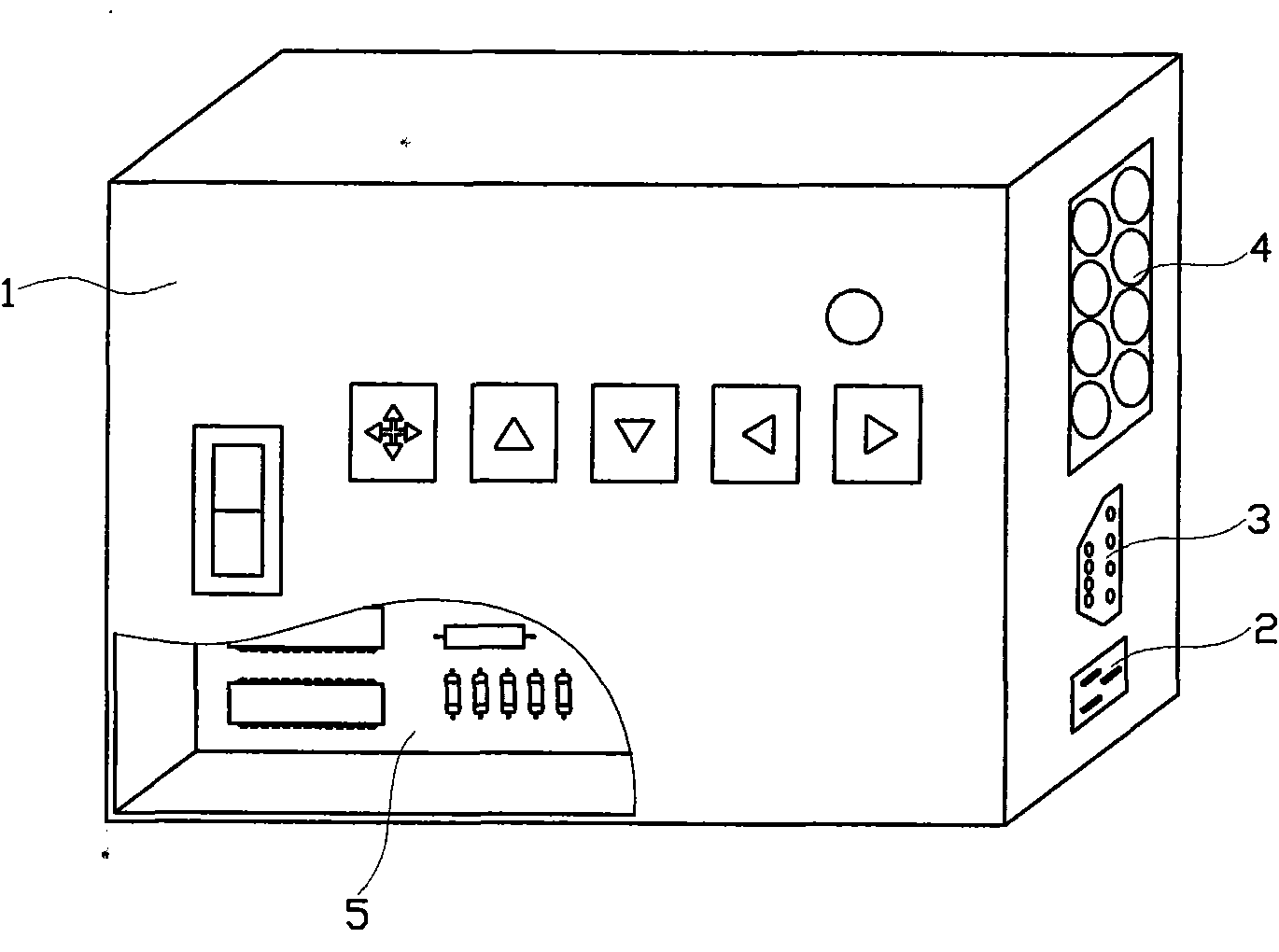

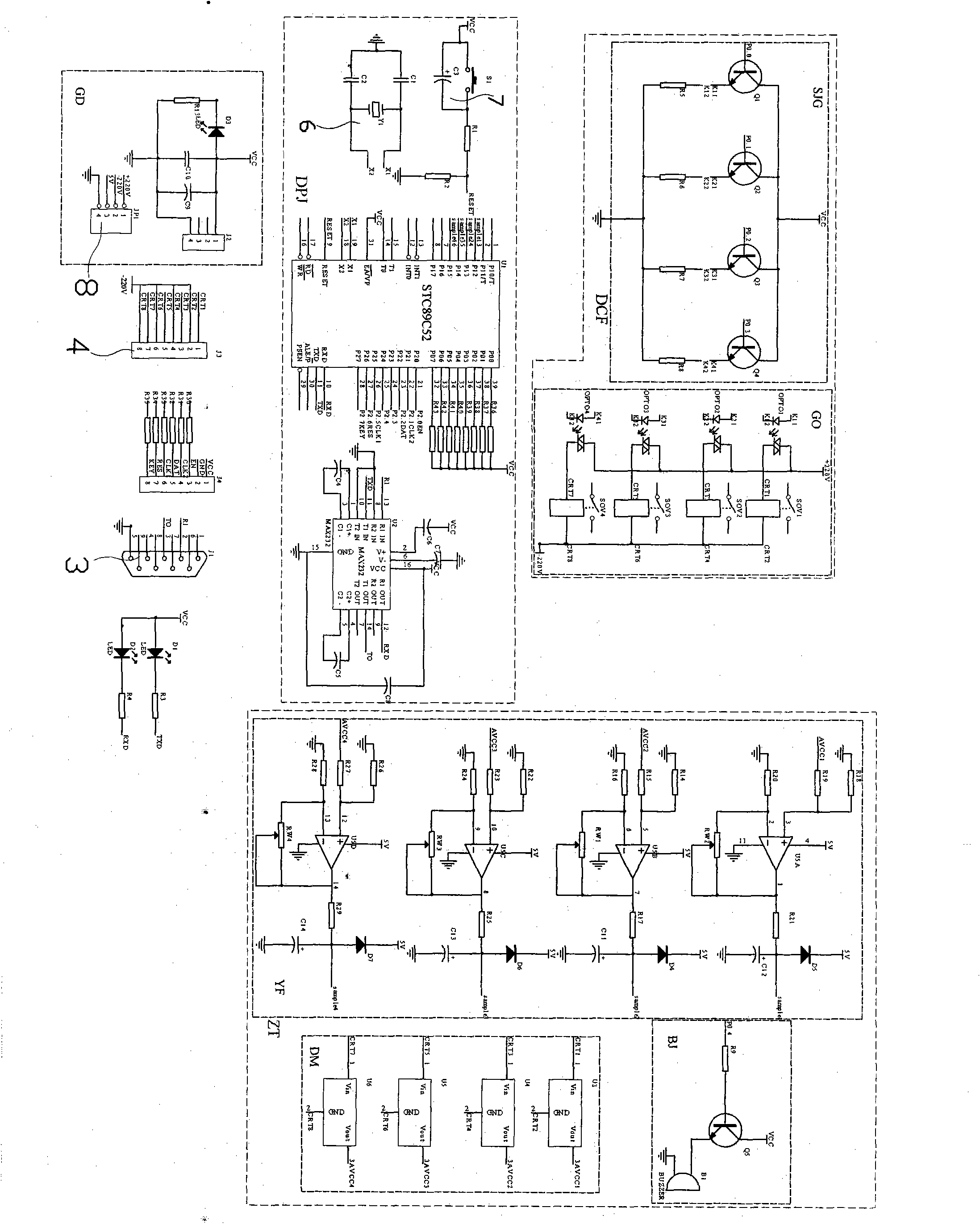

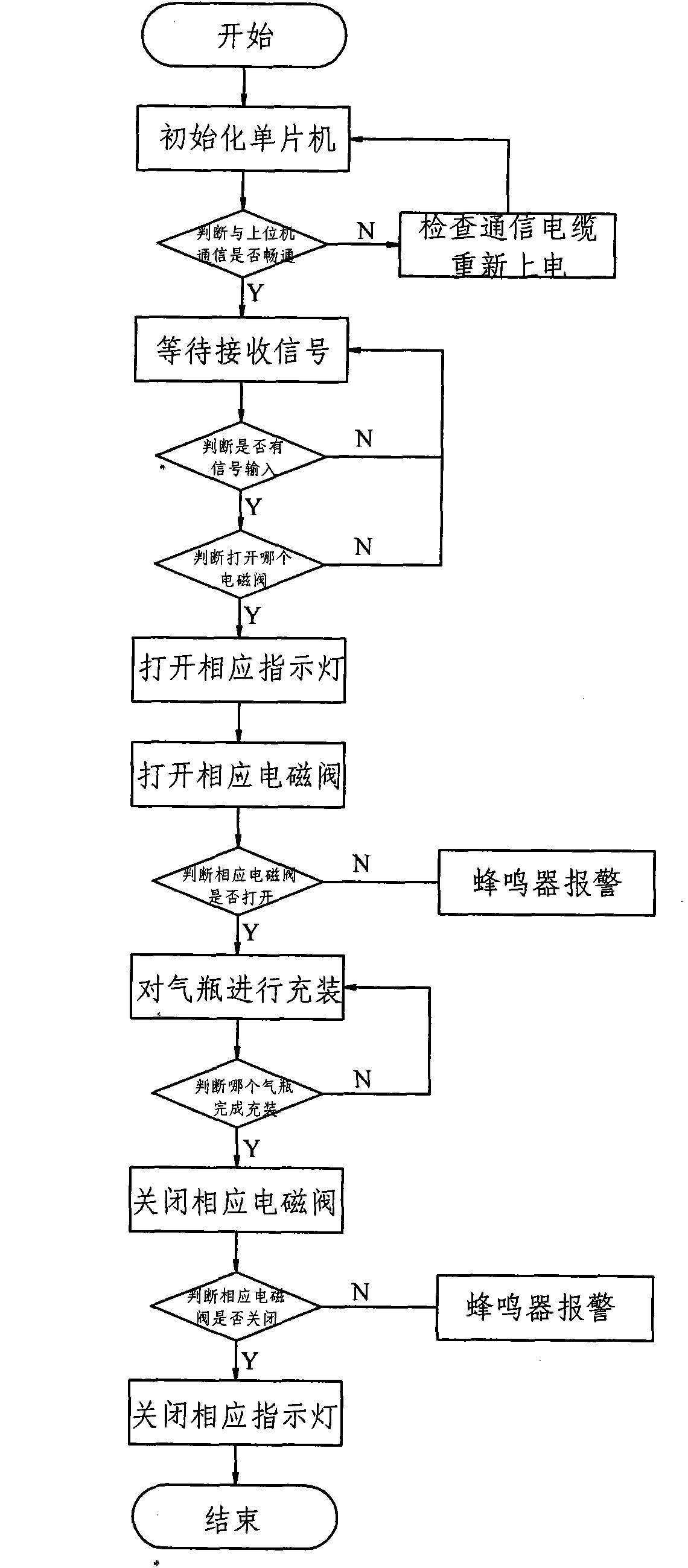

[0021] figure 1 , figure 2 Among them, the hazardous gas cylinder filling control instrument has a housing 1 with a power input terminal 2, an inflation signal input terminal 3, four switch signal output terminals 4, a circuit board 5 inside the housing, and an inflation valve on the circuit board. Control circuit,

[0022] The inflation control circuit has a single-chip microcomputer circuit DPJ connected, a drive circuit DCF and a power supply circuit GD,

[0023] The input end of the power supply circuit is connected to the mains input end on the shell, and the output end of the power supply circuit has the live wire output end of 220 volt mains power +220V, the live wire output end of 220 volt mains power -220V and the Vcc volt output end 5V,

[0024] The single-chip microcomputer circuit has a single-chip microcomputer U1 whose model is STC89C52. The single-chip microcomputer is connected with a clock circuit 6, a reset circuit 7 and a serial communication module U2 wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com