Reciprocating shaft magnetic liquid sealing structure

A technology of magnetic liquid and sealing structure, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of sealing life and sealing pressure reduction, increase of sealing medium leakage rate, loss of magnetic liquid, etc., to improve sealing life and the effect of sealing and pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0022] A reciprocating shaft magnetic liquid sealing structure, the structure includes: a first bearing 4, a first magnetic isolation ring 6, a first pole piece 7, a first O-shaped rubber seal ring 8, a permanent magnet 10, a second O-shaped rubber seal The ring 12, the second pole shoe 13, the second magnetic isolation ring 14, and the second bearing 16 are close to the inner boss of the outer casing 3 in turn, and the end cover 18 is fixed on the outer casing 3 with screws 17, and the second bearing 16 is pressed tightly. ; When in use, inject magnetic liquid into the inner ring surface of the permanent magnet 10, and install the above-mentioned sealing structure on the reciprocating shaft 1 plated with polytetrafluoroethylene 5.

[0023] The first bearing 4 and the second bearing 16 adopt linear bearings of the same type.

[0024] The structure of the first pole piece 7 and the second pole piece 13 are exactly the same.

[0025] The inner ring surface of the first pole sho...

Embodiment approach 2

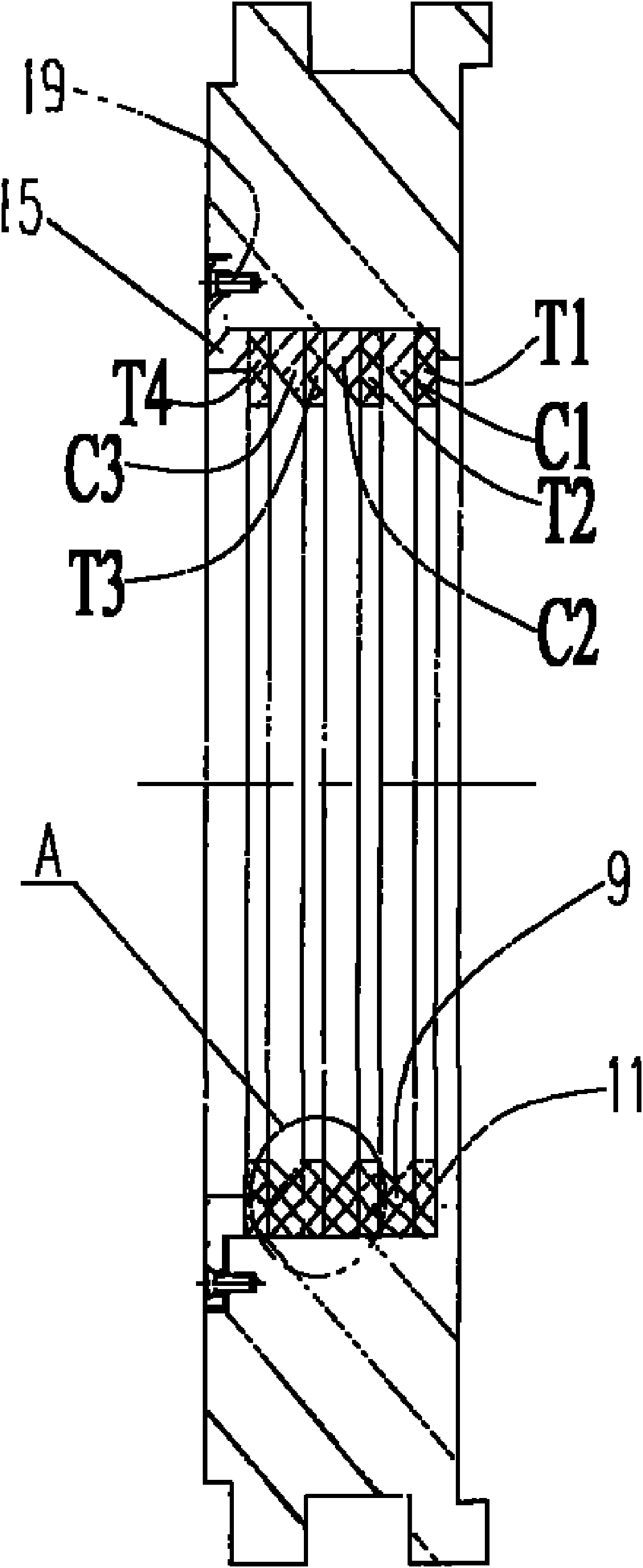

[0028] The difference from Embodiment 1 is that the first elastic ring T1, the first trapezoidal seal teeth C1, the second elastic ring T2, and the second trapezoidal seal are closely spaced in the middle stepped hole on the inner ring surface of the second pole piece 13. Tooth C2, third elastic ring T3, third trapezoidal sealing tooth C3 and fourth elastic ring T4, see figure 2 .

Embodiment approach 3

[0030] The difference from Embodiment 1 is that the first elastic ring T1, the first trapezoidal seal tooth C1, the second elastic ring T2, ..., the The seventh trapezoidal sealing tooth C7, the eighth elastic ring T8, the eighth trapezoidal sealing tooth C8, the ninth elastic ring T9, see Figure 7 , 8 .

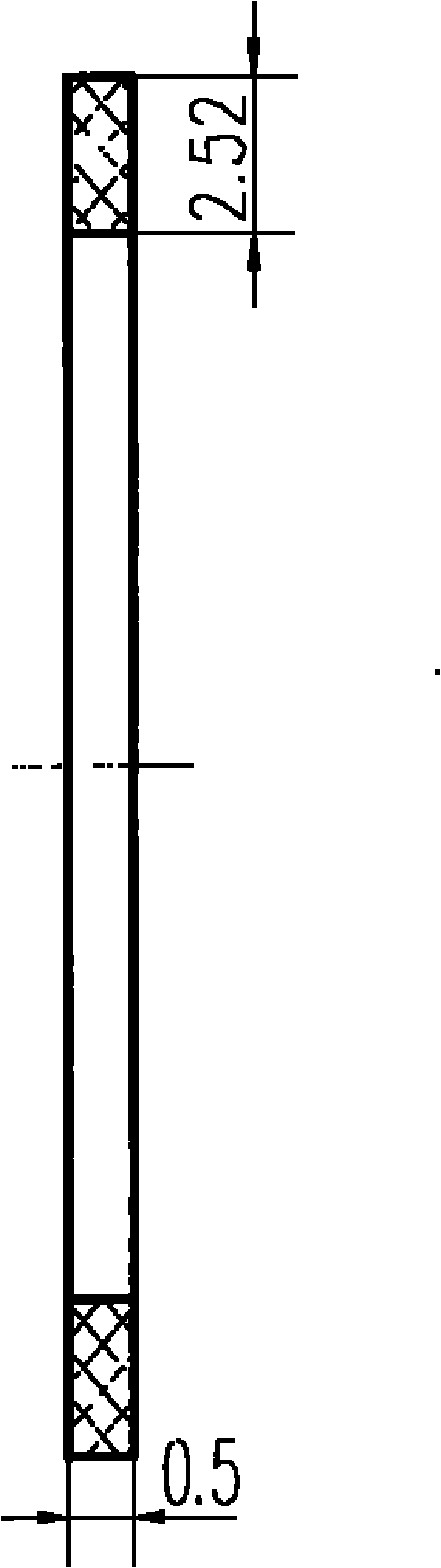

[0031] The tooth shape parameters of the trapezoidal sealing tooth C described in the embodiment are: tooth height 2.5mm, tooth width 0.5mm, inclination angle 45 degrees, see Figure 5 ; The thickness of the elastic ring is 0.5mm, and the difference between the inner and outer diameters is 2.52mm, see Figure 4 .

[0032] On the surface of the reciprocating shaft 1 described in the embodiment, a groove with a depth of 0.1mm is machined, the axial length of the groove is greater than or equal to 4×(thickness of all trapezoidal seal teeth+thickness of all elastic rings), in the groove A polytetrafluoroethylene film 5 with a thickness of 0.1mm is coated in the tank. Due t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com