Three-dimensional shock absorbing support

A three-dimensional shock absorption and support technology, which is applied in the direction of earthquake resistance, building components, buildings, etc., can solve the problems of weak torsion resistance, torsion deformation of irregular structures, etc., achieve large horizontal deformation, improve seismic performance, and reduce damage the dangerous effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

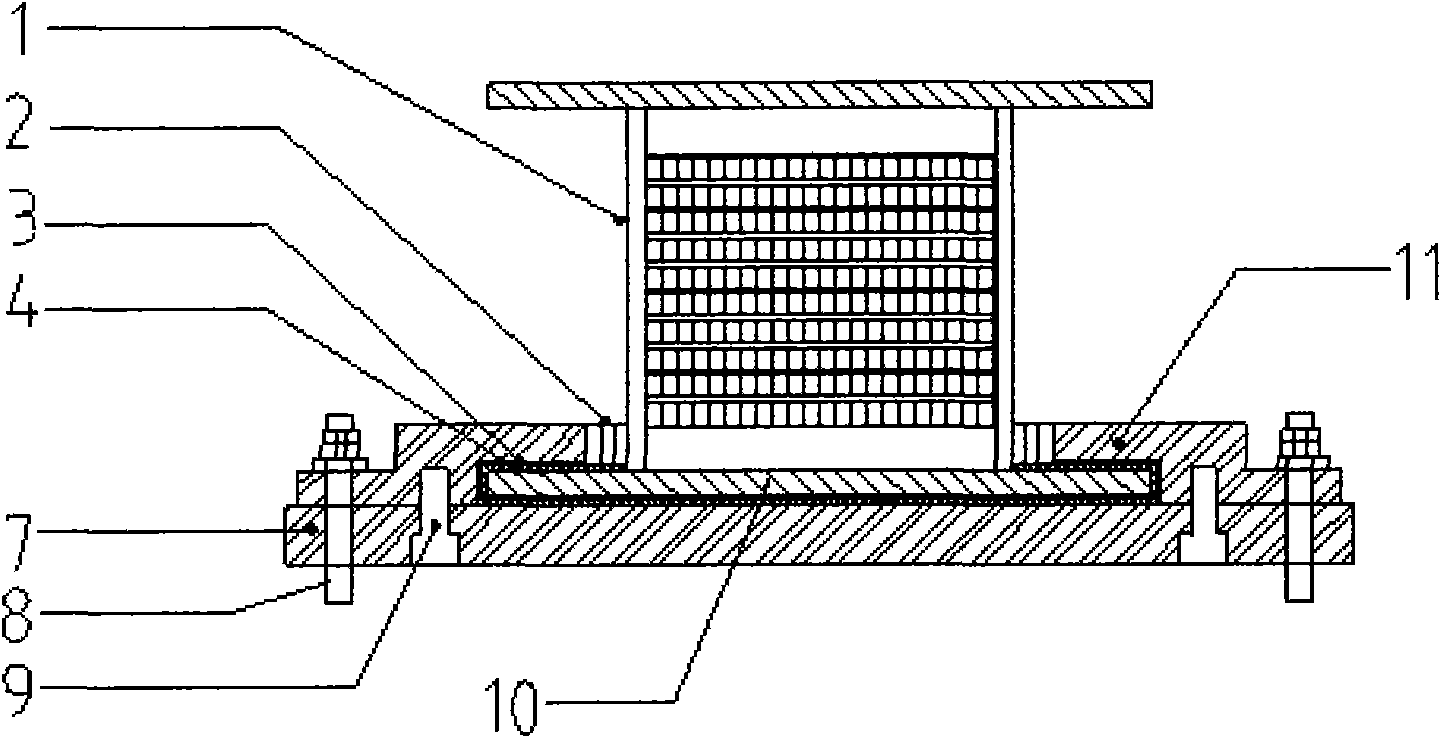

[0021] refer to figure 1 The lower connecting plate 10 of the laminated rubber bearing 1 is buckled in the basin-type steel bearing 7, and a polytetrafluoroethylene plate 4 is inlaid on the bottom upper surface of the basin-type steel bearing 7, and the polytetrafluoroethylene plate 4 is preferably round Shape, the lower surface of the lower connecting plate 10 of the laminated rubber bearing 1 is inlaid with a stainless steel plate. The stainless steel plate can be a circular mirror-finished stainless steel plate 3 . The inner flange 11 of the pot-type steel bearing 7 is used to limit the horizontal and vertical translation of the laminated rubber bearing 1 and the rotation around the vertical direction. The mirror surface mounted on the lower connecting plate 10 of the laminated rubber bearing 1 The stainless steel plate 3 and the polytetrafluoroethylene plate 4 inlaid on the upper surface of the bottom of the pot-type steel support 7 form a rotating contact surface. Since ...

specific Embodiment 2

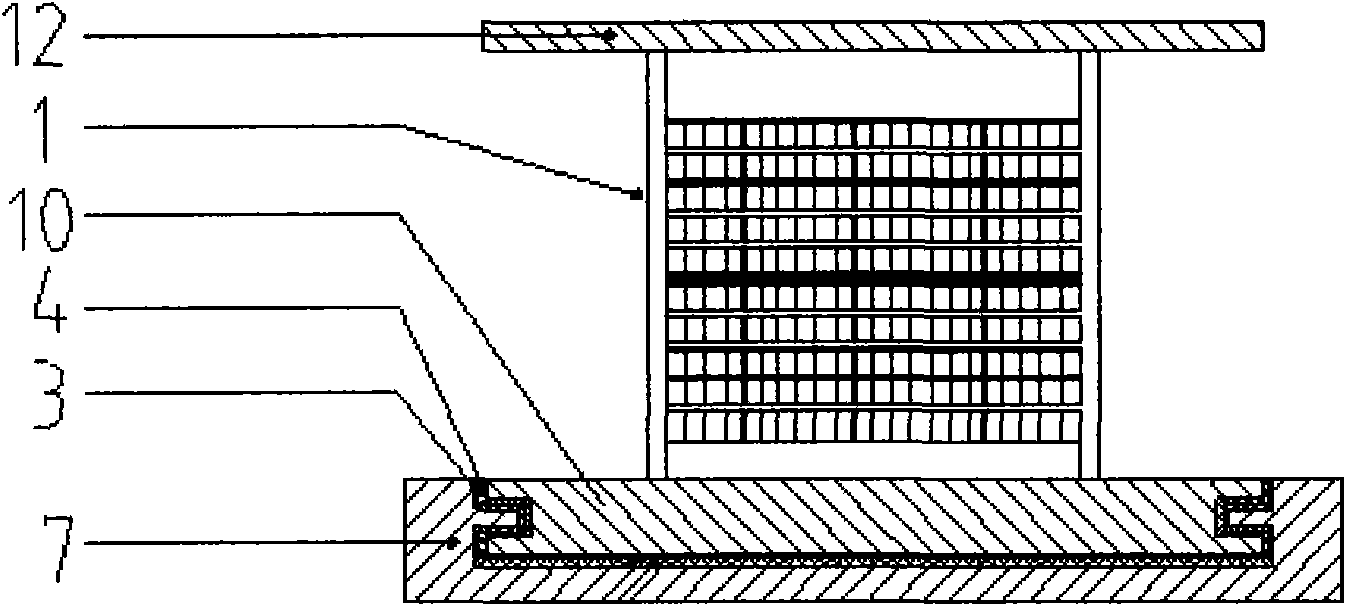

[0022] refer to figure 2 , The specific embodiment 2 is similar in structure to the specific embodiment 1, the difference lies in the way the basin-type steel bearing 7 constrains the lower connecting plate 10 of the laminated rubber bearing 1 . In this example, a depression is provided on the lower connecting plate 10, and a tooth-shaped protrusion matched with the depression is provided on the basin-type steel support 7. The lower connecting plates 10 of the laminated rubber bearing 1 are connected in a toothed interlocking manner, constraining the horizontal and vertical translation and rotation around the vertical direction of the lower connecting plates 10 of the laminated rubber bearing 1 . There can be one set of tooth-shaped protrusions constituting the tooth-shaped interlocking structure, or multiple sets, and the number of the tooth-shaped protrusions is not limited. But to reduce friction, a set is preferred.

specific Embodiment 3

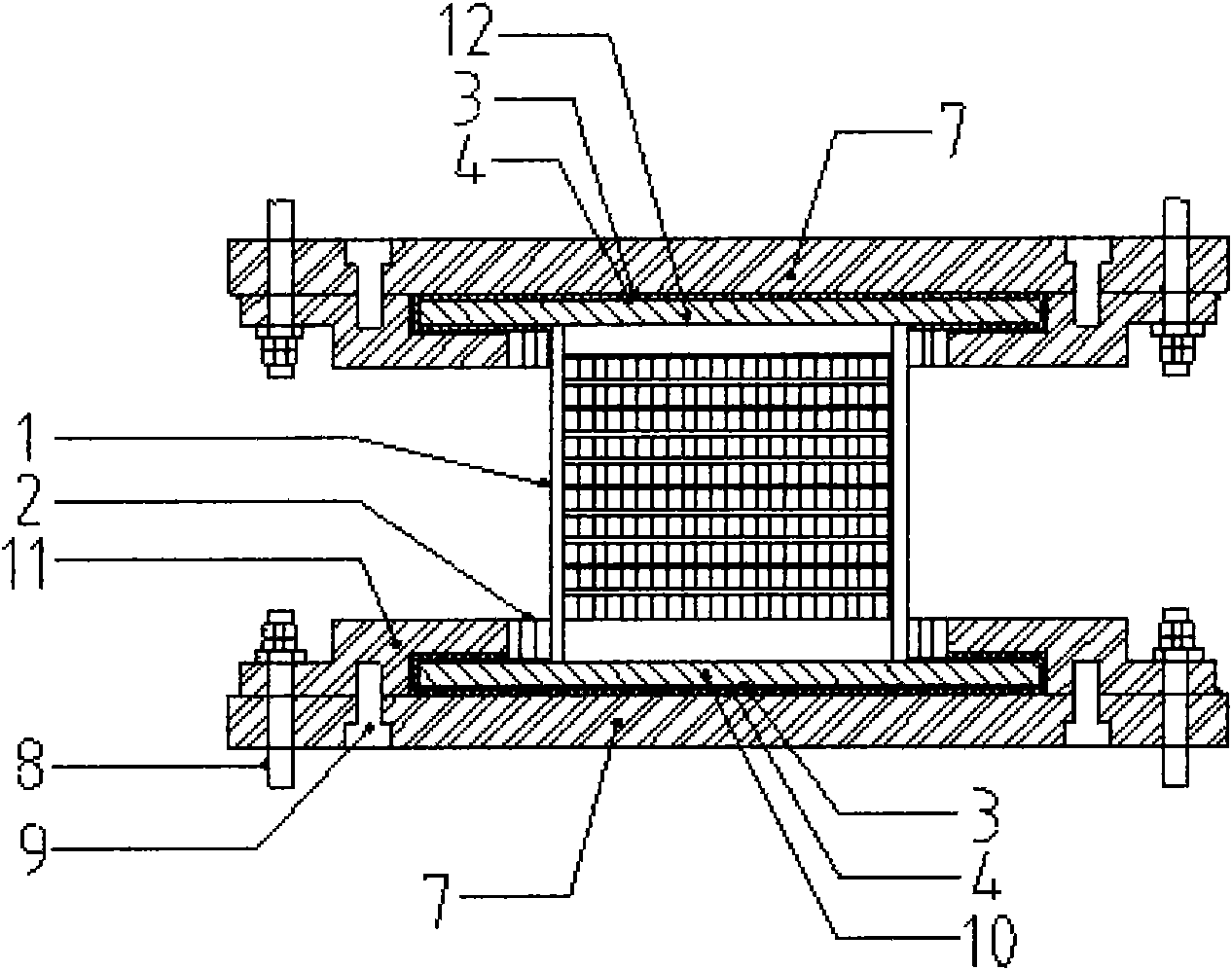

[0023] refer to image 3 , the three-dimensional shock-absorbing bearing mainly includes a laminated rubber bearing 1 and a basin-type steel bearing 7 . Among them, there are two pot-type steel bearings 7, an upper connecting plate 12 is arranged above the laminated rubber bearing 1, and a lower connecting plate 10 is arranged below, and the upper connecting plate 12 and the lower connecting plate 10 are connected with the basin-type steel bearing 7. matching. And the upper connecting plate 12 and the lower connecting plate 10 are respectively buckled and placed in the basin-type steel bearings 7 that they match, and the two basin-type steel bearings 7 are respectively used to restrain the upper connecting plate 12 and the lower connecting plate 1 of the laminated rubber bearing 1 The lower connecting plate 10 can only rotate around the vertical axis of the basin-type steel bearing 7 in the basin-type steel bearing 7 . The laminated rubber bearing 1 is fixedly connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com