High-pressure syringe connection tube

A technology of high-pressure syringes and connecting tubes, which is applied in the field of medical equipment, can solve the problems of anti-reflux valve device failure, drug confusion, and failure to achieve injection speed, etc., and achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

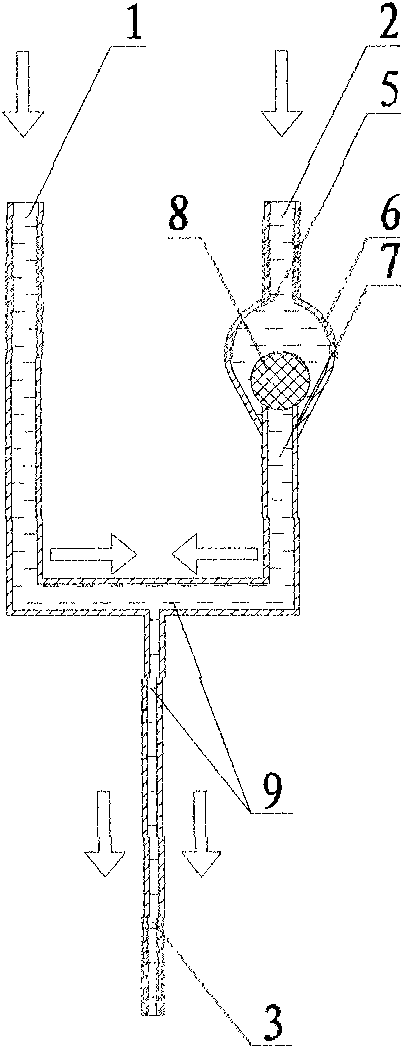

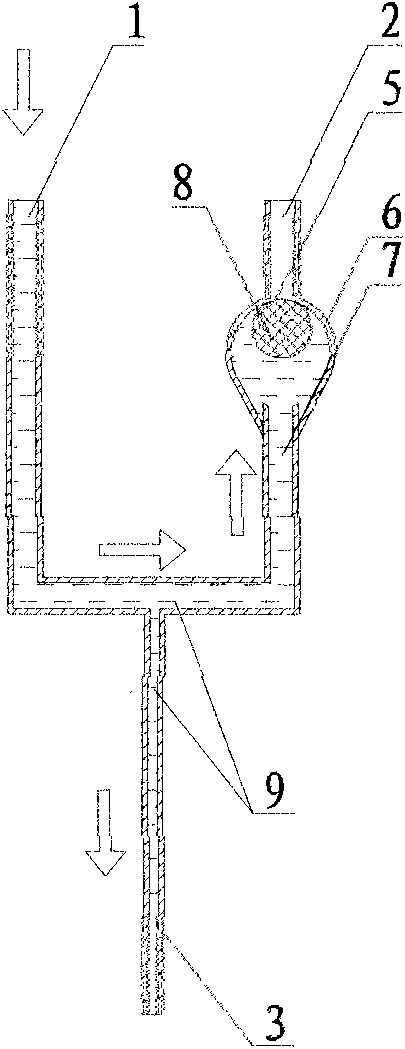

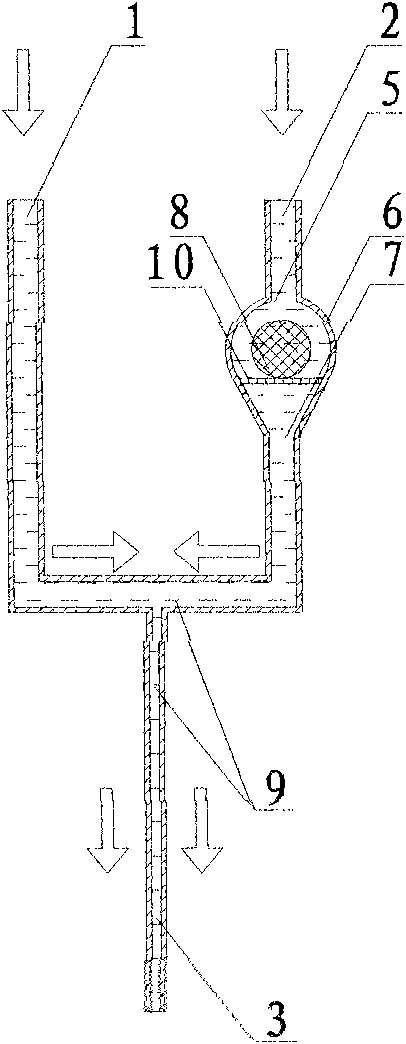

[0018] like figure 1 , figure 2 As shown, Embodiment 1 of the present invention is a connecting pipe for a high-pressure syringe, comprising a left input end 1, a right input end 2 and an output end 3, wherein the right input end 2 is provided with an anti-reflux valve device, and the anti-reflux valve The device includes an inlet pipe 5, an intermediate body 6 and an outlet pipe 7 connected sequentially from top to bottom, and the outlet pipe 7 partly extends into the intermediate body 6, and has a flow hole at the lowermost end of the extending part (in the figure not shown), or the side of the pipe that extends into the part is provided with a flow groove (not shown in the figure), the inner cavity of the intermediate body 6 is an inverted cam ball, and the intermediate body 6 is provided with a buoyancy force greater than its own gravity in the liquid The ball float 8 (made of lightweight materials). When injecting input at the left input terminal 1 and right input term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com