Tobacco stem drawing machine

A technology for pulling rods and tobacco leaves, which is applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of high labor intensity, difficult operation, low work efficiency, etc., and achieves convenient rod pulling operation, novel principle and reasonable design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

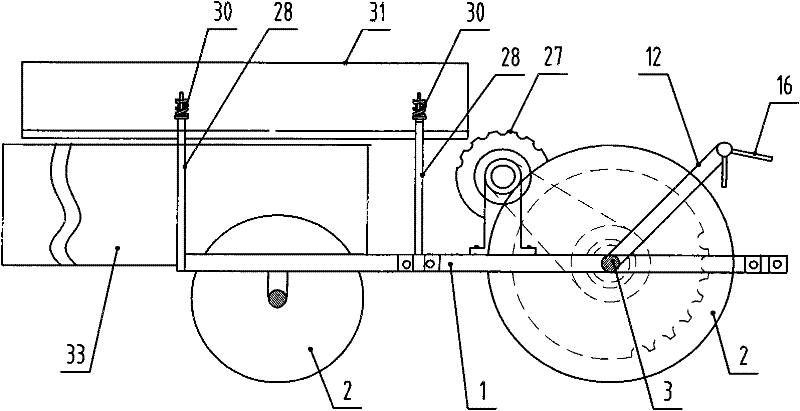

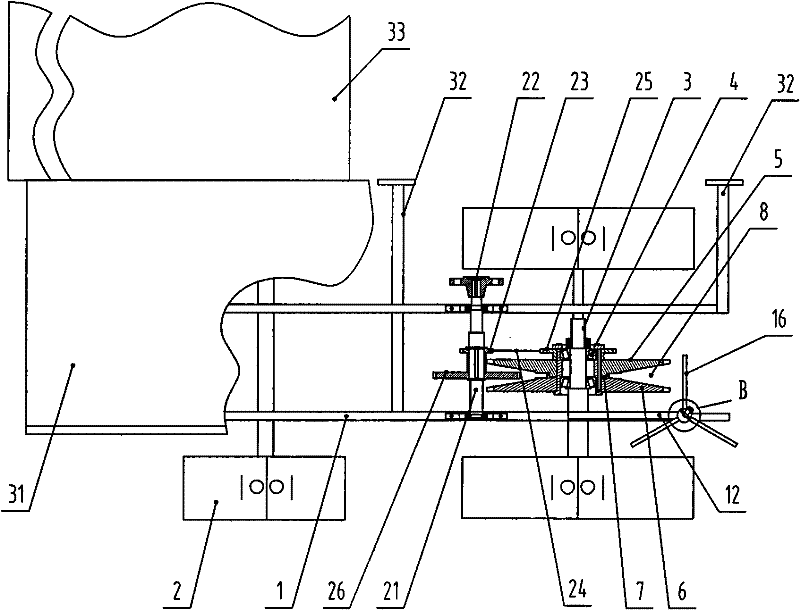

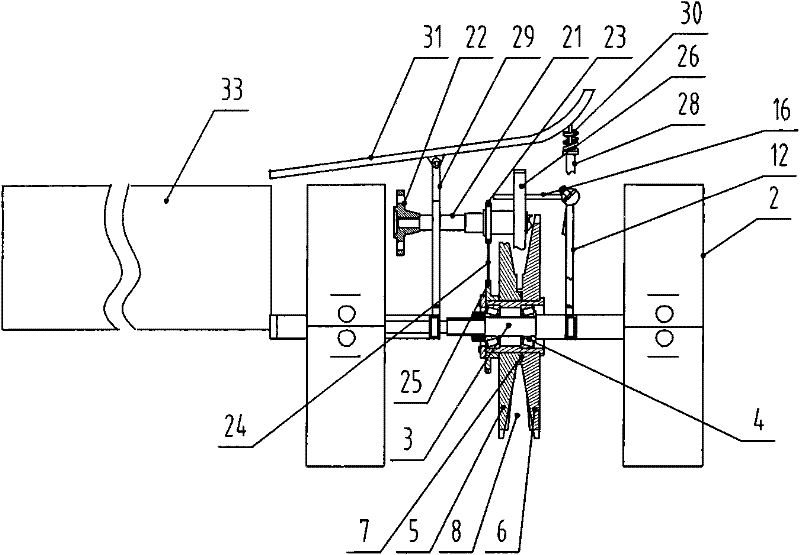

[0026] Such as Figure 1 ~ Figure 7 As shown, the tobacco rod pulling machine of the present invention includes a frame 1, four walking wheels 2 are arranged on the lower part of the frame, and a power transmission device, a rod pulling device and a rod supporting device are provided on the frame 1. The rod device is connected with a chain drive.

[0027] The rod-drawing device includes a horizontal shaft 3 horizontally arranged on the frame 1. A rod-drawing cone disk 5 and a rod-drawing cone disk 6 are provided on the horizontal shaft 3 through a bearing 4, between the rod-drawing cone disk 5 and the rod-drawing cone disk 6 There is an open spring washer 7 sleeved on the horizontal axis 3, the two opposite circumferential surfaces of the rod cone 5 and the rod cone 6 have a certain taper, and the rod cone 5 and the rod cone 6 are formed between Annular clamping cavity 8 with wide outside and narrow inside. Two arc-shaped teeth 9 and a wedge ring 10 are provided on the two oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com