Shock absorber for silicone-oil belt pulley

A technology for pulleys and shock absorbers, which is applied to springs/shock absorbers, vibration suppression adjustment, mechanical equipment, etc. It can solve the problems of less heat dissipation structure design and no air convection of shock absorbers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

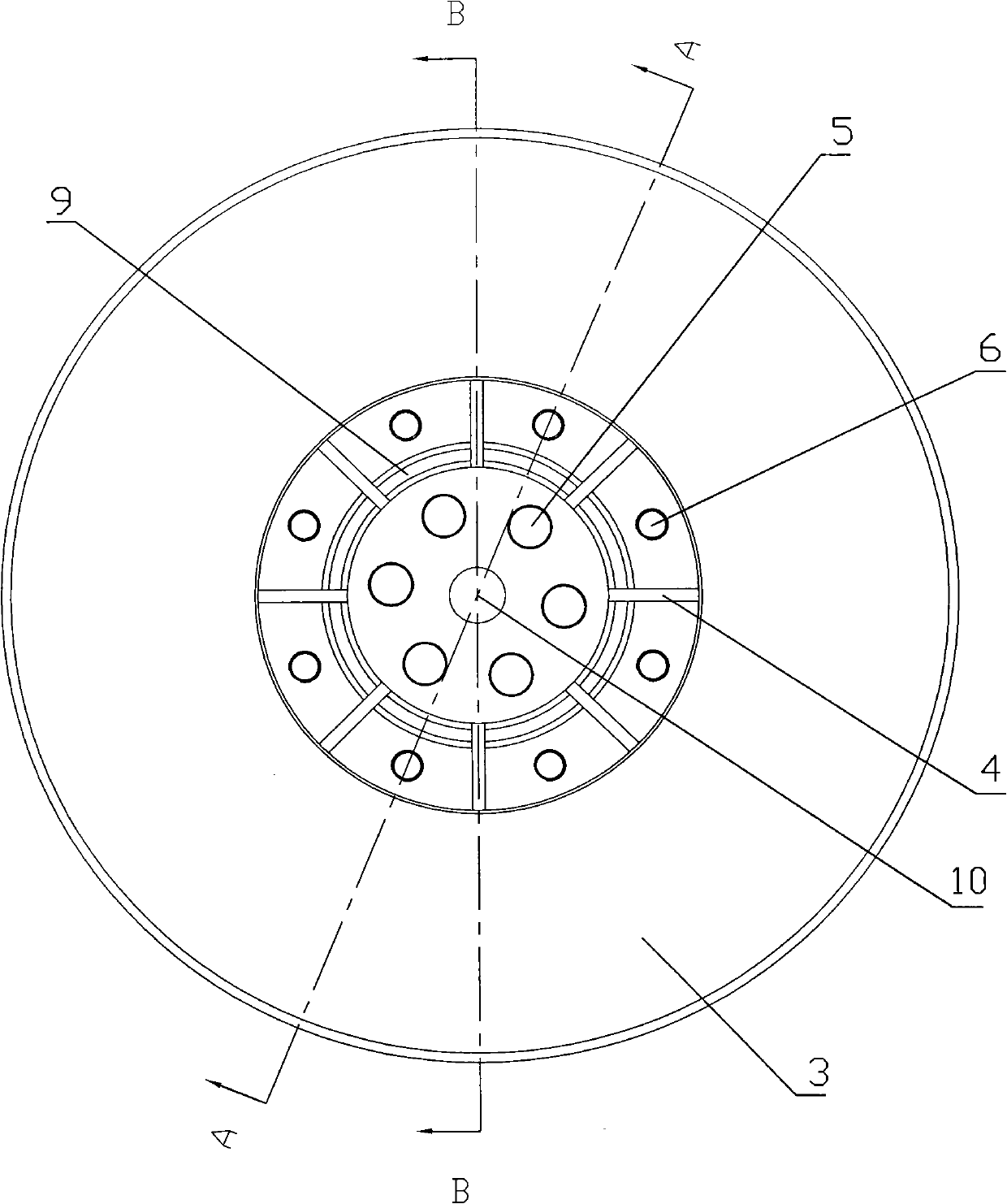

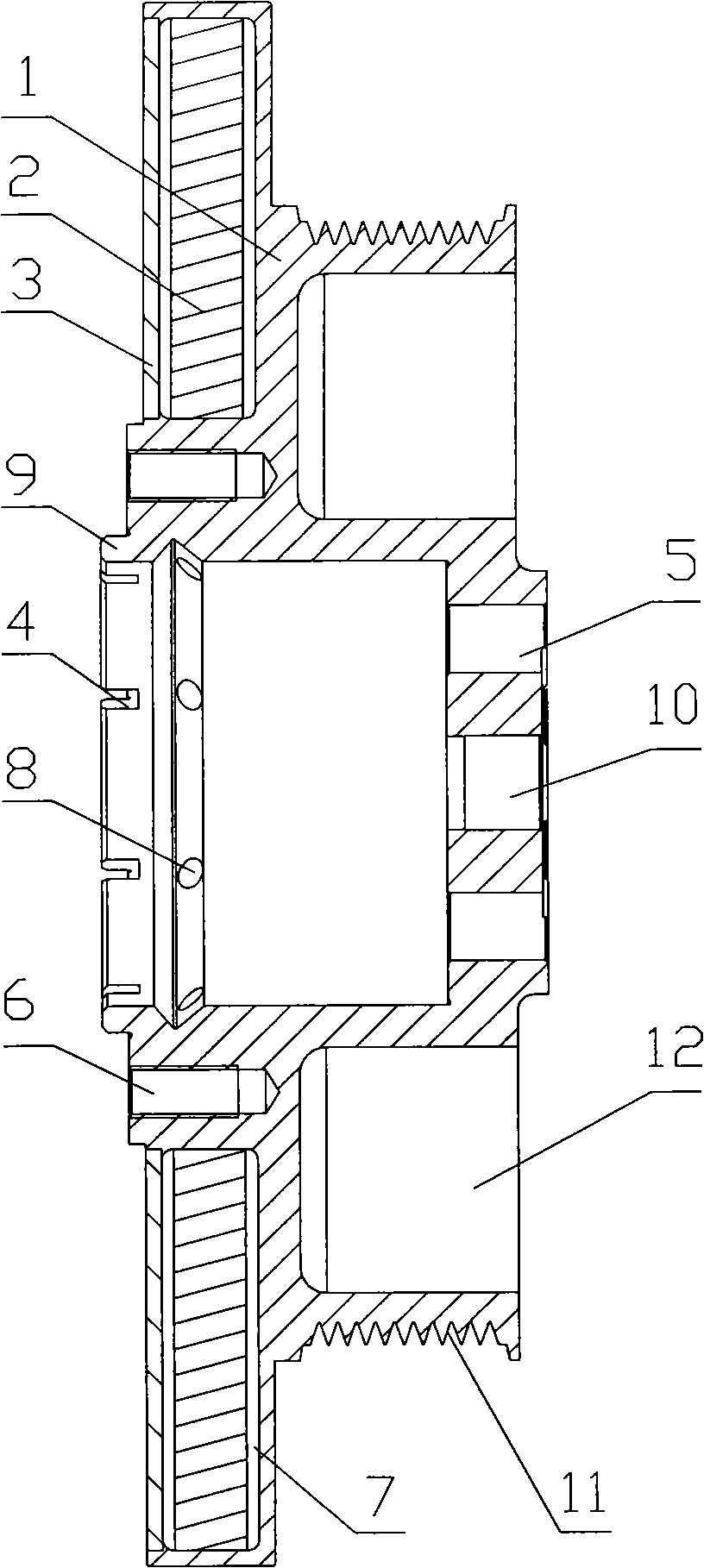

[0014] Referring to the accompanying drawings, the silicon oil pulley shock absorber includes a pulley body 1, and the radially inner circumference of the front end of the pulley body 1 is provided with an external belt pulley positioning notch 9, and the radially outer circumference is provided with an annular inertial block chamber, and the annular inertial block chamber is composed of The ring groove on the front end surface of the pulley body 1 and the front cover plate 3 sealed and mounted on the ring groove are composed. The ring inertia block cavity is provided with an inertia block 2 that is suitable for the shape of the inner cavity. The inertia block 2 and the ring inertia block Silicone oil 7 is filled in the gap between the cavity and the cavity, and the silicone oil 7 is mainly filled in the two axial ends of the inertia block 2 . An annular heat dissipation groove 12 is arranged on the outer periphery of the rear end surface of the pulley body 1, and the annular h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com