Production method of fine-denier hollow nylon 6FDY filament

A production method and nylon technology, which are applied in the manufacture of hollow filaments, single-component polyamide rayon filaments, and rayon manufacturing, to achieve the effects of reducing floating filaments, improving post-processing performance, and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Raw materials: 100 parts by weight of PA6 slices with a viscosity of 2.5±0.05; special masterbatches for fine-denier nylon are added with the second main group metal salt—calcium chloride, and the addition amount is 6% of the weight of nylon slices; special masterbatches for fine-denier nylon The dosage is 2% of the mass of PA6 slices.

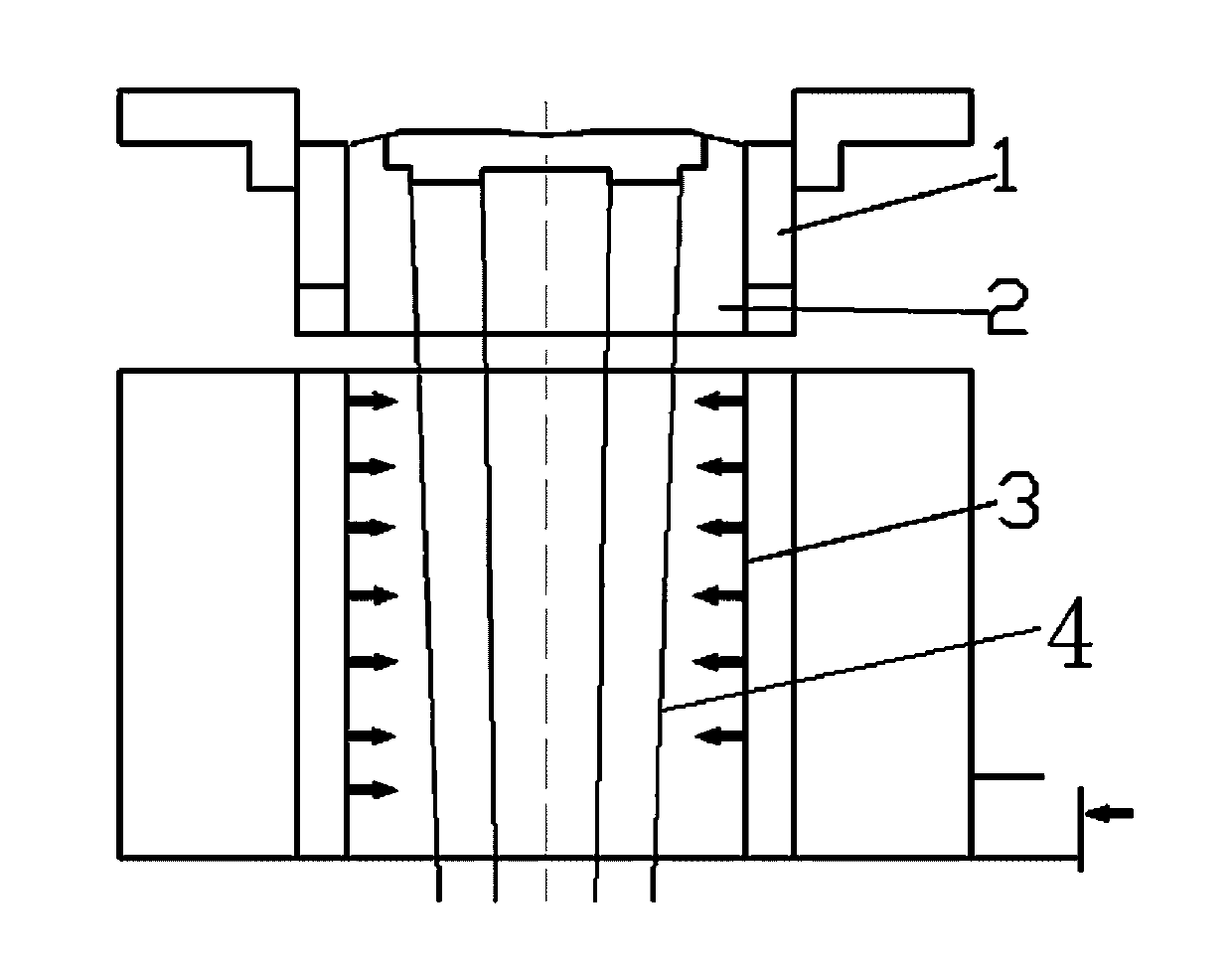

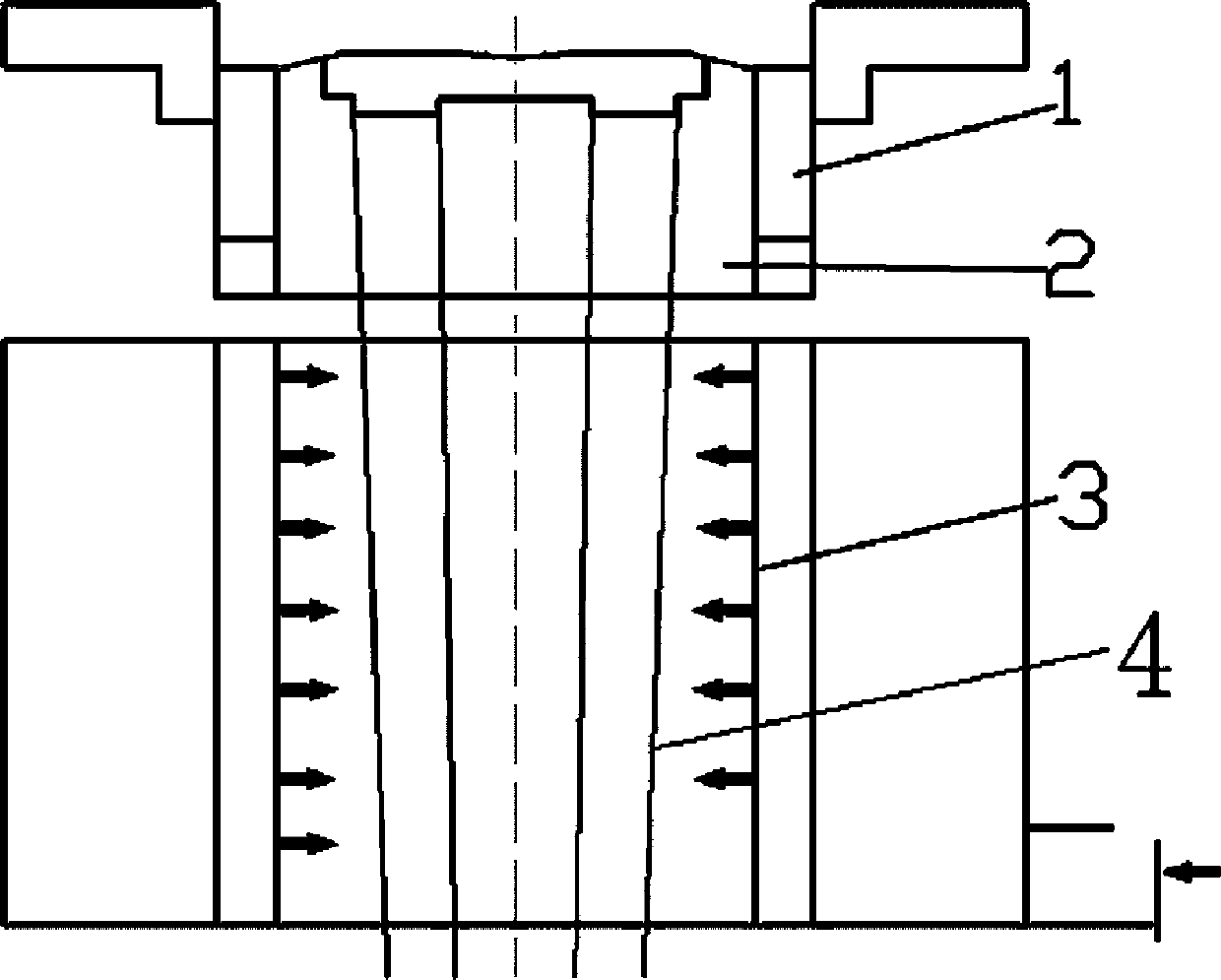

[0024] Equipment parameter adjustment: the position of the cluster point is 600mm away from the spinneret; the hole diameter of the hollow spinneret

[0025] The diameter is 0.20mm, and the aspect ratio is 1:3mm; the metal sand filter adopts 60~80 mesh; the length of the ring blowing sleeve of the ring blowing device is 50cm, and the length of the polycooling air pipe is 40cm.

[0026] Process conditions: the wind speed of the ring blower is 0.3m / s, the temperature is 28°C, and the humidity is 80%; the temperature of the spinning box is 283°C; the temperature of the screw extruder is 260~290°C, and the head pressure in the spinning asse...

Embodiment 2

[0028] Raw materials: 100 parts by weight of PA6 slices with a viscosity of 2.5±0.05, adding the second main group metal salt—calcium acetate, the amount of which is 6% of the weight of the nylon slices; the amount of fine-denier nylon masterbatches is PA6 4% of slice mass.

[0029] Equipment parameter adjustment: the position of the cluster point is 600mm away from the spinneret; the hole diameter of the hollow spinneret is 0.20mm, and the length-to-diameter ratio is 1:3mm; the metal sand filter adopts 60-80 mesh; the length of the ring blowing sleeve of the ring blowing device is 50cm , Poly cold air duct length 40cm.

[0030] Process conditions: the wind speed of the ring blower is 0.3m / s, the temperature is 28°C, and the humidity is 80%; the temperature of the spinning box is 282°C; the temperature of the screw extruder is 260~290°C, and the head pressure in the spinning assembly is 12~18Mpa, spinning and winding speed is 4300m / min. The PA6 melt is extruded through a hol...

Embodiment 3

[0032] Raw materials: 100 parts by weight of PA6 slices with a viscosity of 2.5±0.05, fine-denier nylon masterbatches are added with the second main group metal salt—magnesium sulfate, and the amount added is 6% of the weight of nylon slices; the amount of fine-denier nylon masterbatches is 5% of PA6 slice mass.

[0033] Equipment parameter adjustment: the position of the cluster point is 600mm away from the spinneret; the hole diameter of the hollow spinneret is 0.20mm, and the length-to-diameter ratio is 1:3mm; the metal sand filter adopts 60-80 mesh; the length of the ring blowing sleeve of the ring blowing device is 50cm , Poly cold air duct length 40cm.

[0034] Process conditions: the wind speed of the ring blower is 0.3m / s, the temperature is 28°C, and the humidity is 80%; the temperature of the spinning box is 278°C; the temperature of the screw extruder is 260-290°C, and the head pressure in the spinning assembly is 12~18Mpa, spinning and winding speed is 4600m / min. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com