Method for preparing sea buckthorn berry oil from sea-buckthorn pulp

A technology of seabuckthorn fruit oil and seabuckthorn fruit, which is applied in the direction of fat oil/fat production and fat production, can solve the problems of not being high enough, small investment in equipment, low energy consumption, etc., and achieve cost reduction, good product quality, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: prepare seabuckthorn fruit oil from seabuckthorn pulp, and its preparation steps are as follows:

[0018] 1) Ask for 100kg of fresh seabuckthorn fruit pulp obtained by pressing, and measure the oil content of seabuckthorn fruit 2.98kg according to the method of "GB / T 14488.1-2008 Determination of Oil Content in Vegetable Oils" and using a conventional reflux extractor;

[0019] 2) Enzymatic hydrolysis treatment of the seabuckthorn pulp obtained in the above step: using compound pectinase and cellulase to process the seabuckthorn pulp. Be pectinase by mass ratio: compound compound enzyme in the ratio of cellulase=3: 2.0, 120g pectinase is mixed with 80g cellulase, make 200g compound enzyme (wherein pectinase and cellulase are respectively It is the product of Novozymes (China) Biotechnology Co., Ltd., wherein the activity of pectinase is 200000IU / g, and the activity of cellulase is 2000IU / g.; 100kg of seabuckthorn pulp obtained in step 1) is placed in the e...

Embodiment 2~ Embodiment 4

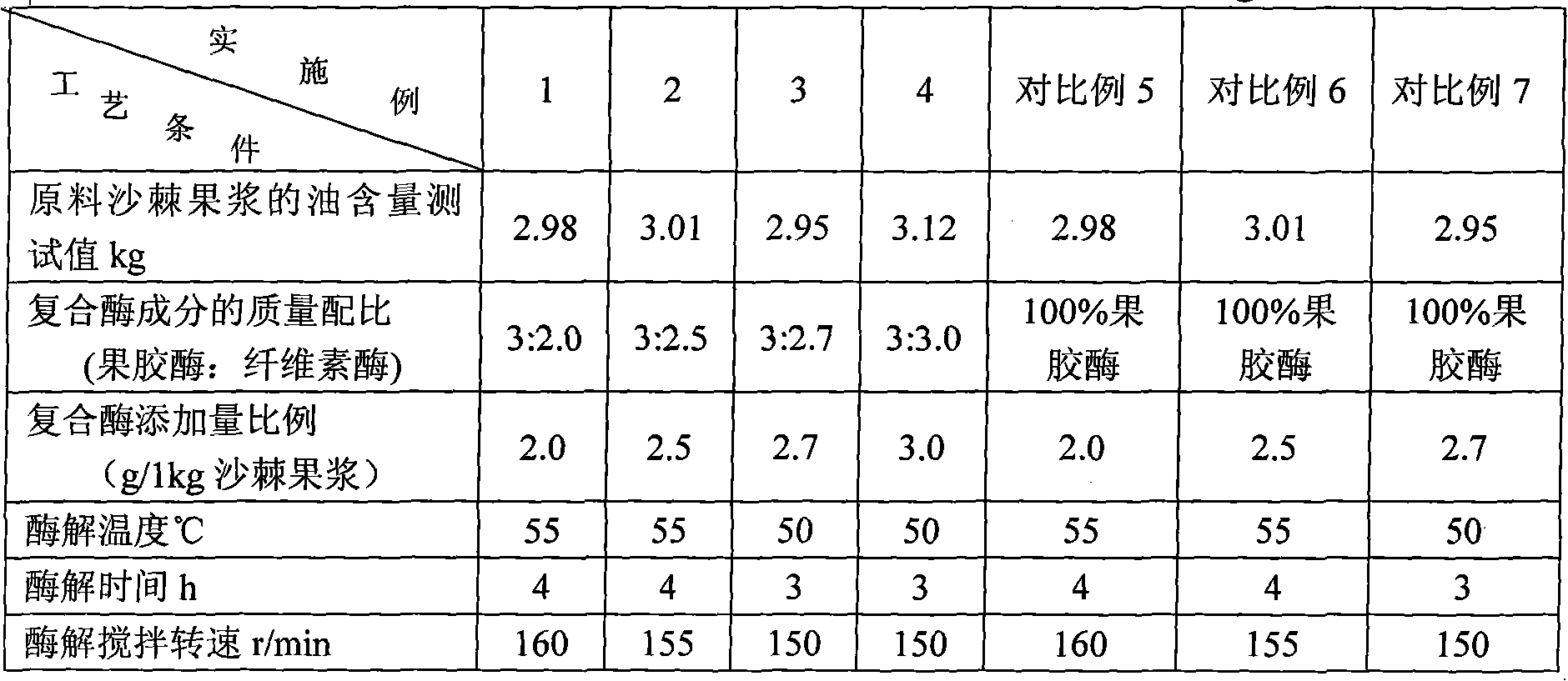

[0022] Embodiment 2~Example 4: Sea-buckthorn fruit oil is produced from fresh sea-buckthorn fruit pulp 100kg, and its preparation step is identical with embodiment 1, and its process condition and its oil yield value are shown in Table 1, other technological operations and The description is the same as in Example 1.

[0023] Embodiment 5~Example 7 are comparative examples, prepare seabuckthorn fruit oil from fresh seabuckthorn fruit pulp, the fresh sea buckthorn fruit pulp raw materials that get are respectively identical with embodiment 1~embodiment 3, and its preparation steps are the same as those in the implementation Same as Example 1, but only use pectinase alone to treat seabuckthorn pulp, its process conditions are respectively the same as those of Examples 1 to 3, its process conditions and oil yield values are shown in Table 1, and other process operations and descriptions are the same as Example 1 is the same.

[0024] Table 1 (the raw material of each embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com