Regulating device of belt wheel

An adjustment device and pulley technology, applied in the field of machinery, can solve the problems of not having adjustable driven wheels, unstable sliding of coupling parts, and uncertain sliding distance and position, so as to achieve precise adjustment, change of cutting angle, and increase of adjustable sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

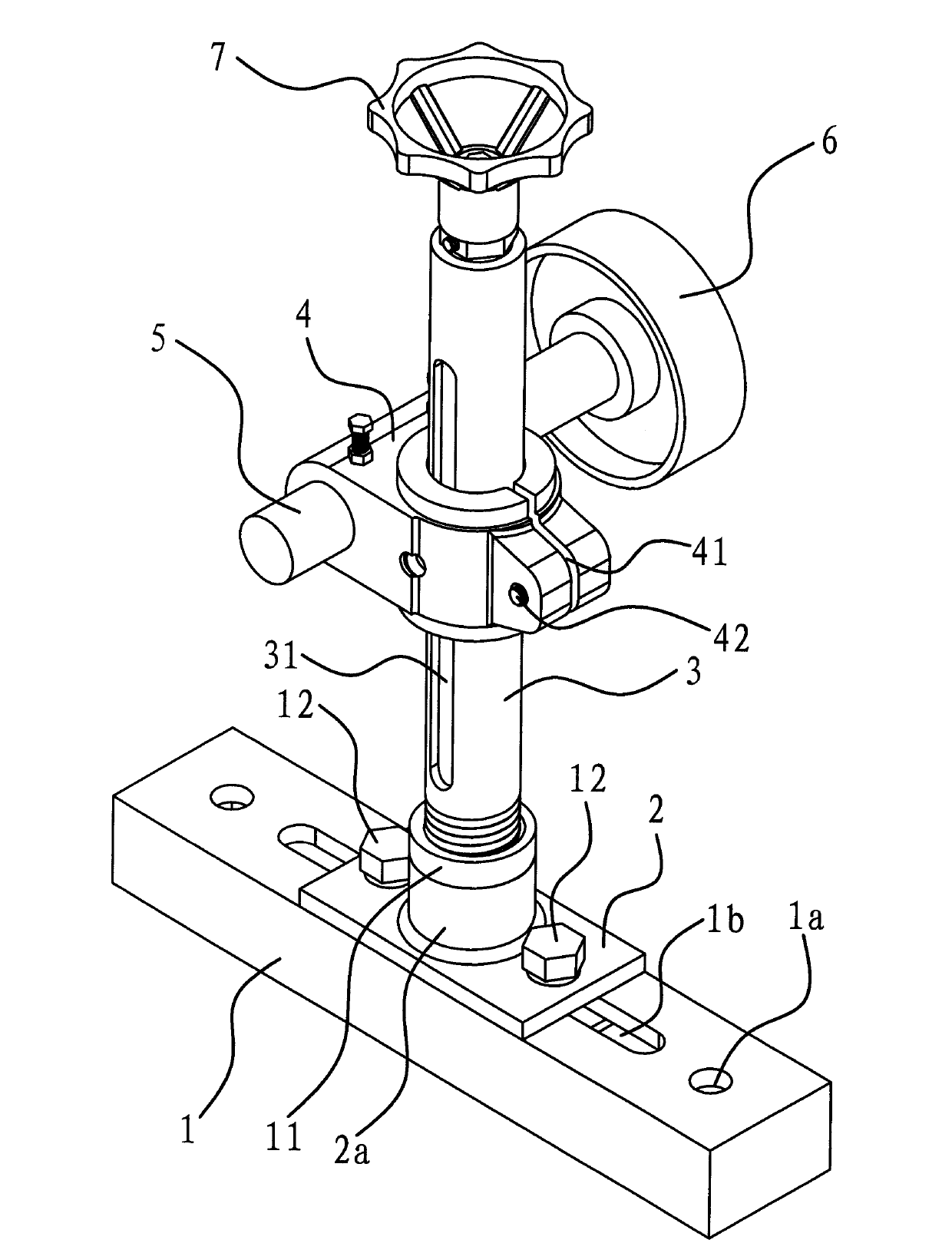

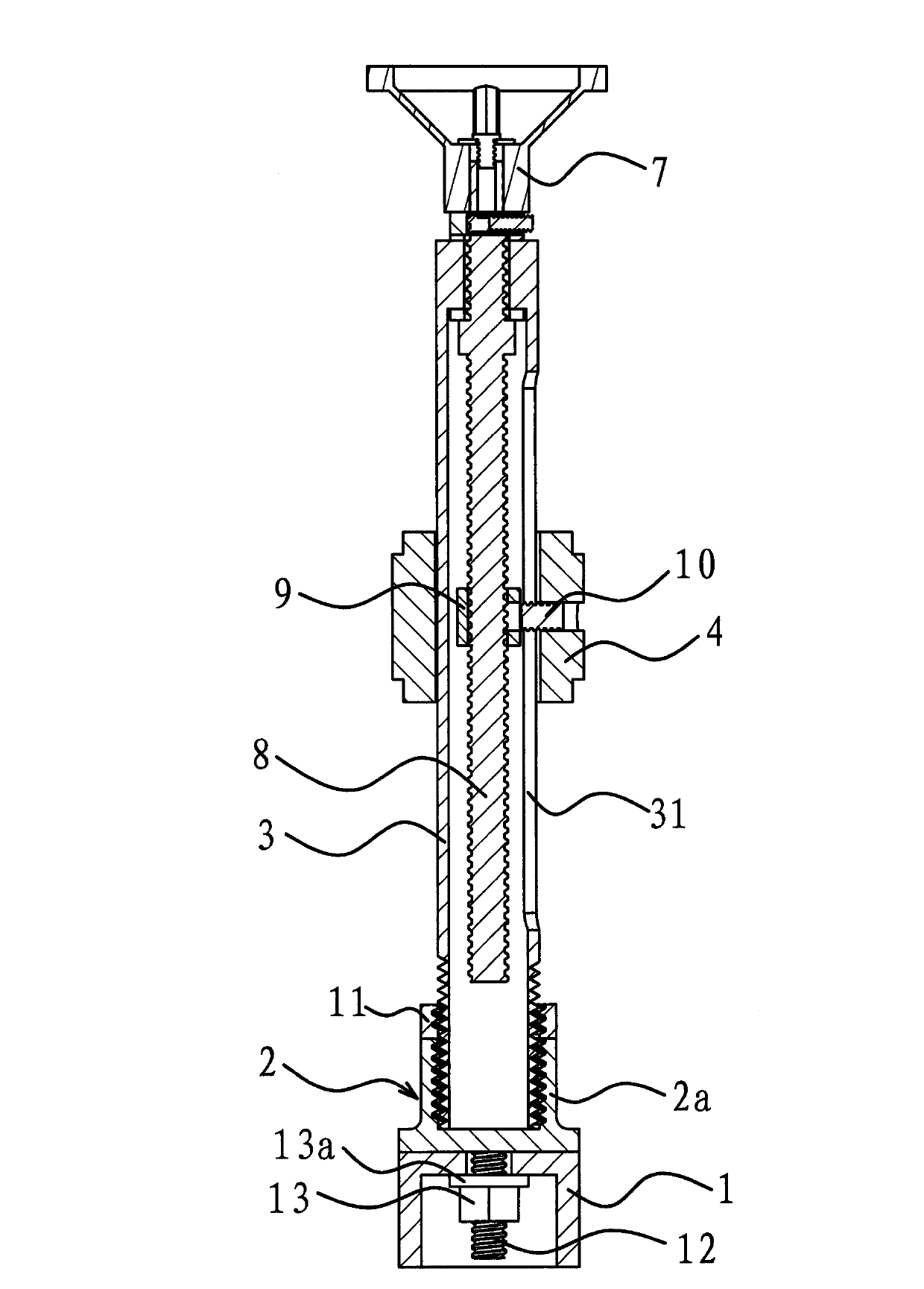

[0025] Such as figure 1 As shown, the adjusting device of the pulley comprises a base 1, a positioning part 2, a vertical shaft 3, a rotating shaft 5, a pulley 6 and a coupling part 4. The adjusting device is used for adjusting various types of belt drives, generally it is used for belt polishing machines.

[0026] Specifically, the base 1 is in the shape of a strip, and is generally provided with fixing holes 1a at both ends thereof; bolts 12 and other connecting parts pass through the fixing holes 1a to fix the base 1 on the frame or base of the polishing machine or on the ground, The abrasive belt is sheathed on the pulley 6, thus drawing, the way that the regulating device is fixed has diversity and the extensiveness of the fixed position.

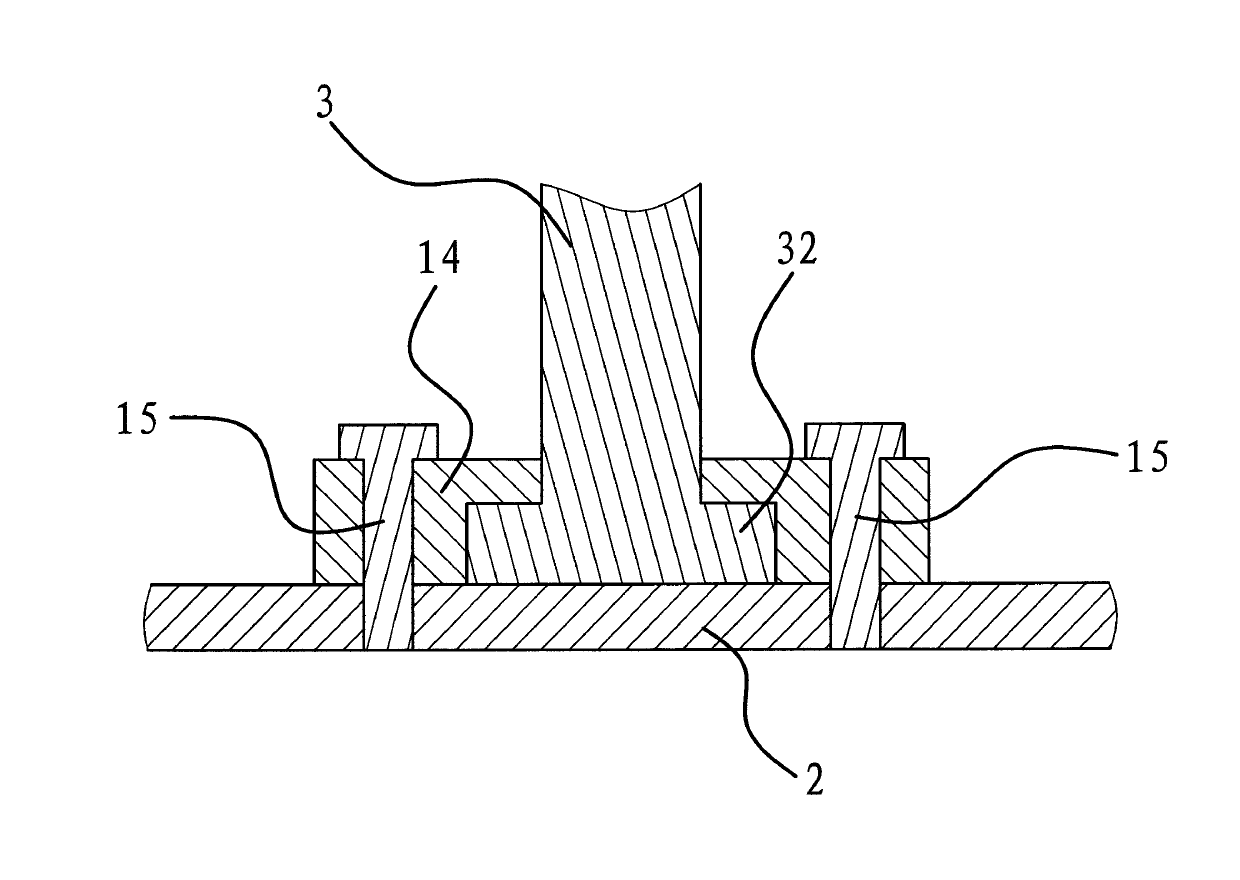

[0027] The base 1 is made of channel steel and has a linear guide groove 1b on the waist surface, and the vertical axis 3 is perpendicular to the waist surface of the base 1 . A sheet-shaped positioning piece 2 is provided on the low...

Embodiment 2

[0036] The structure and principle of this embodiment are basically the same as those of the first embodiment, except that the positioning member 2 is fixedly connected to the base 1 or the above-mentioned positioning cap 2a is fixedly connected to the base 1 . Therefore, among the three steps of the above-mentioned adjustment process, only steps 2 and 3 can be operated.

Embodiment 3

[0038] The structure and principle of this embodiment are basically the same as that of the first embodiment, except that the lower end of the vertical shaft 3 is fixedly connected to the positioning member 2 . Therefore, among the three steps of the above-mentioned adjustment process, only steps 1 and 3 can be operated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com