Welding rod spiral extrusion press with double-fastened reamer head

A technology of pressure coating machine and reamer head, which is applied in the direction of welding medium, manufacturing tools, welding equipment, etc., can solve the problems of difficult operation, increased thrust, and high labor intensity of drug refilling, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

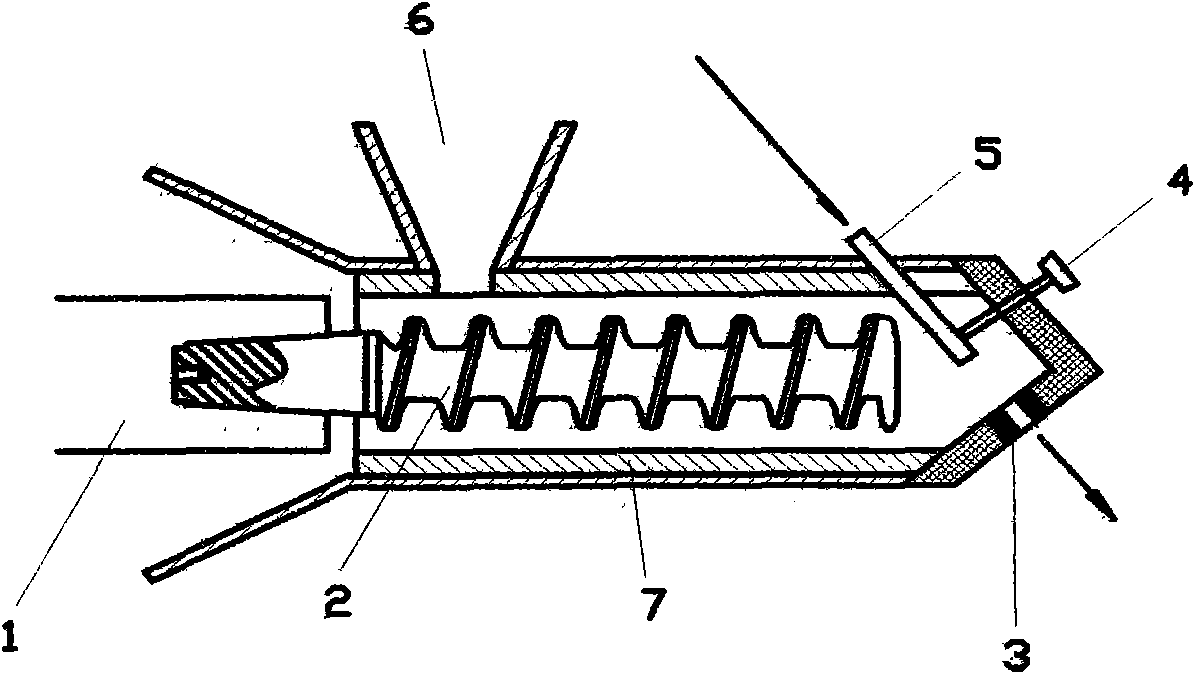

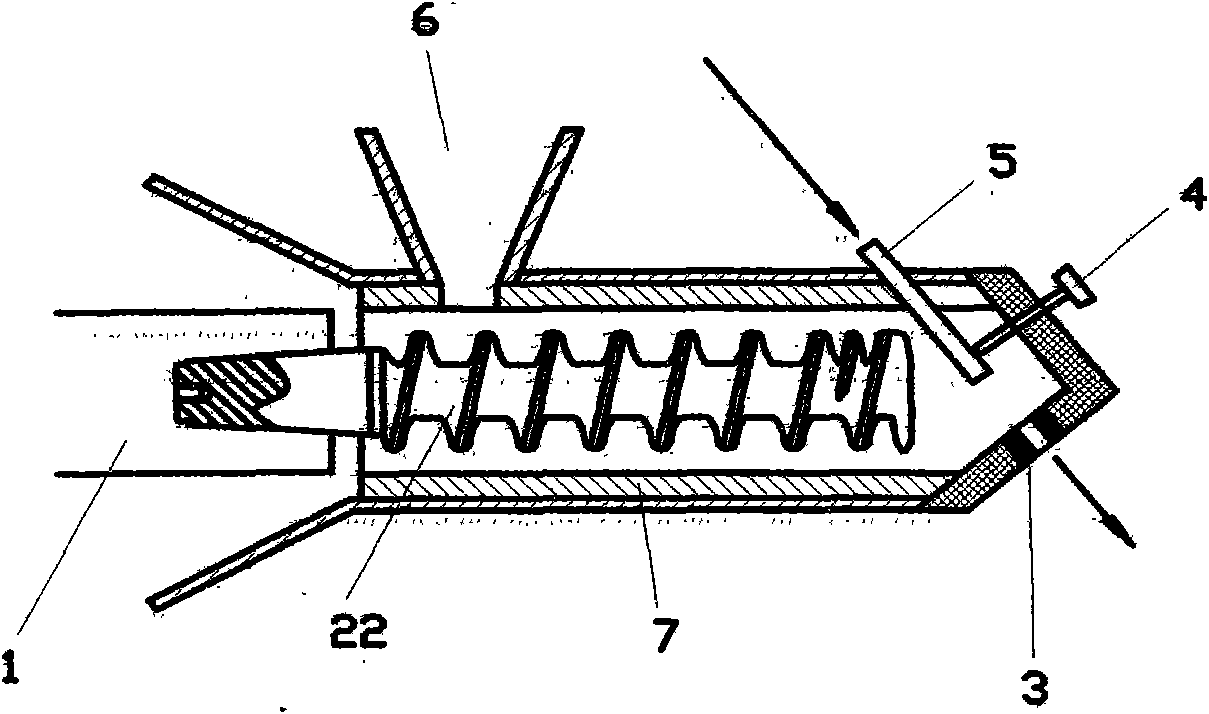

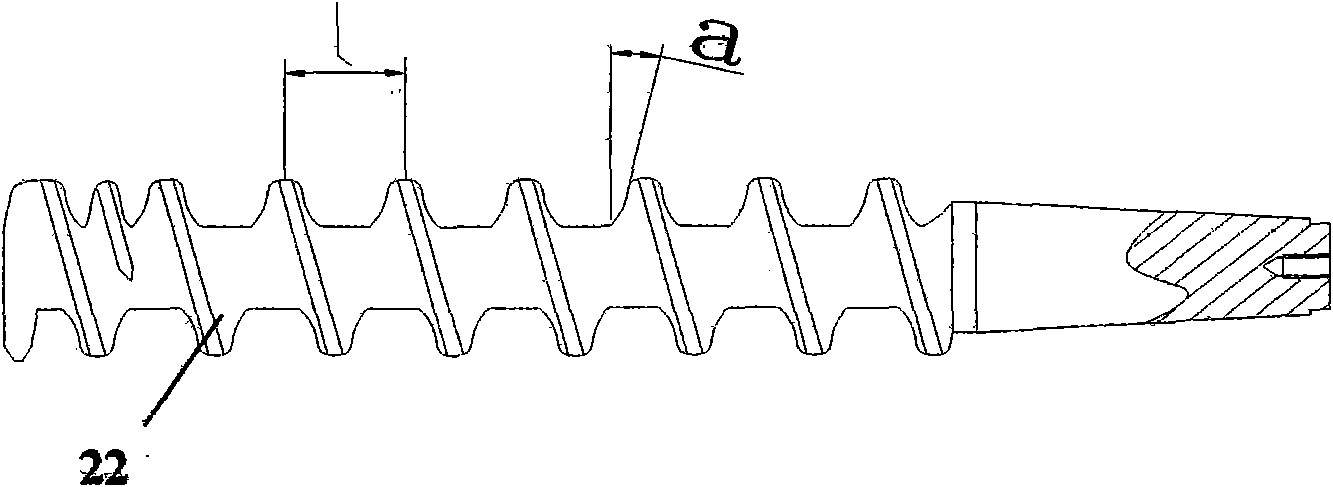

[0023] figure 2 It is a structural schematic diagram of the present invention; image 3 yes figure 2 Schematic diagram of the structure of the medium spiral reamer.

[0024] The invention provides a welding rod spiral coating machine with a double-button reamer head. The welding rod spiral coating machine includes: a medicine powder cylinder liner 7, and the upper end of the medicine powder cylinder liner 7 is provided with a medicine filling port 6; A single-head spiral reamer 22; one end of the spiral reamer 22 is connected to the transmission spindle 1 of the reducer, and the other end of the helical reamer 22 is adjacent to the wire feeding mechanism.

[0025] The wire feeding mechanism includes: a wire guide 5 and a sizing die 3, the wire guide 5 and the sizing die 3 communicate with the medicine powder cylinder liner 7; the wire guide 5 is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com