Internally concave double-edge open type pot mouth with tin retaining plates

An open-type, tin-shield technology, which is applied in the direction of assembling printed circuits with electrical components, can solve problems such as low work efficiency, unsuitable for large-scale batch processing, and easy to form virtual soldering of contacts, etc., to ensure sufficiency and firmness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

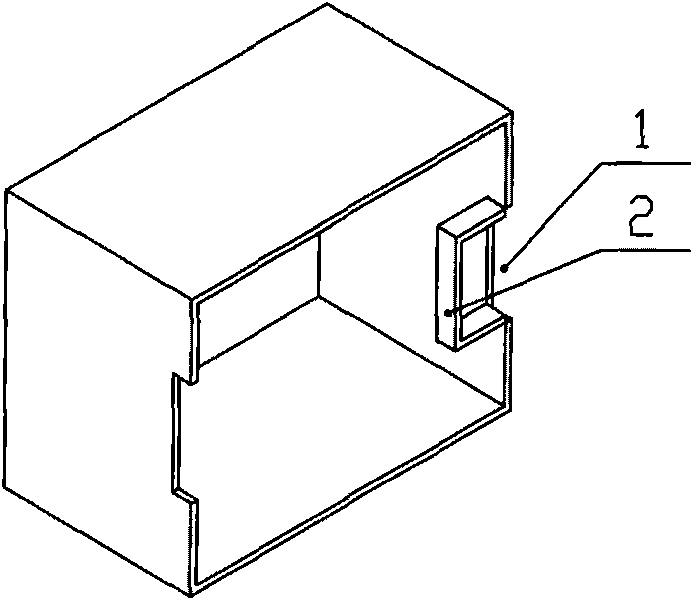

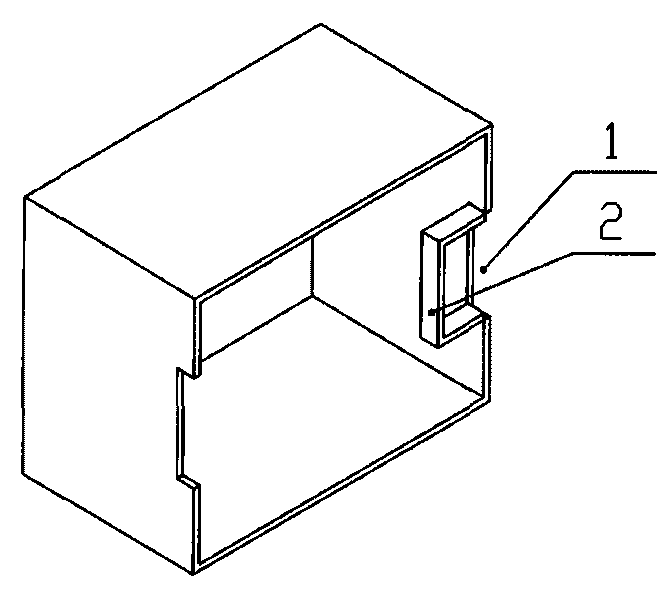

[0012] Such as figure 1 Shown is a double-sided opening type spout with an inner concave tin stopper. The spout has a rectangular mouth structure. A tin overflow port 1 is provided on the opposite side of the edge of the spout. An annular tin baffle 2 is arranged inside the opening. The solder overflow opening 1 is a rectangular gap with a depth of 3-6 mm.

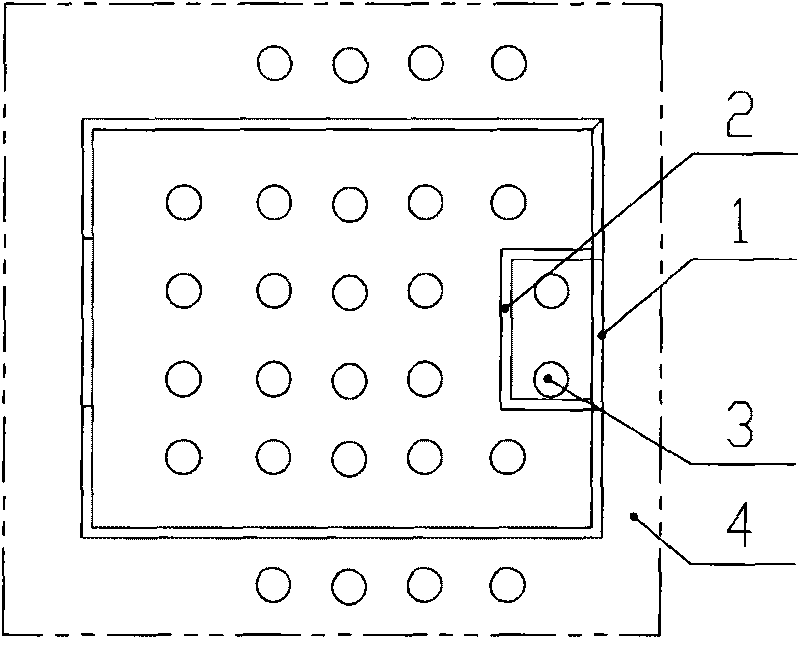

[0013] Such as figure 2 As shown, the electronic components 3 on the PCBA board 4 above the solder overflow port 1 need to be shallow soldered or do not need to be soldered. By setting the depth of the solder overflow port 1, the tin liquid can flow out of the solder overflow port 1 in advance to control welding In order to prevent the surrounding tin liquid from spreading to the electronic component 3, the ring-shaped tin baffle 2 is provided to stop the tin liquid on the periphery of the ring-shaped tin baffle 2 on the ring-shaped tin baffle 2 to ensure the ring-shaped tin stop The welding effect of the electronic compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com