Method for detecting sectional profile of transition section of gas turbine combustion chamber

A cross-sectional profile, gas turbine technology, applied in the direction of measuring devices, special data processing applications, instruments, etc., can solve the problems of long manufacturing cycle, easy to produce misjudgment, difficult processing and verification, etc., to achieve shortened cycle, reliable mold repair data, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

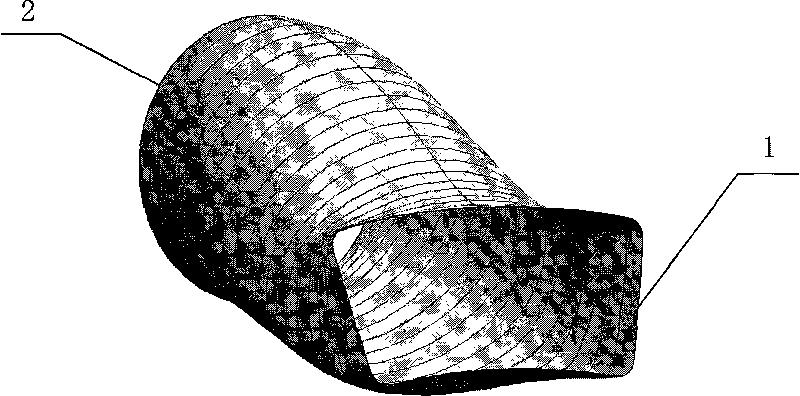

[0033] A method for detecting the profile degree of a transition section of a combustion chamber of a gas turbine, comprising the following steps:

[0034] Step 1: Support and position the tested part on the measuring bracket;

[0035] There are irregular margins around the hollow and thin-walled parts after stamping, and the support positioning is difficult to start, which must be considered in the processing technology of the parts. That is, during stamping and forming, the machining allowance outside the main body of the part is dimpled, and then the process hole is drilled according to the dimple, and the process hole and the part surface are used to realize the support and positioning of the tested part.

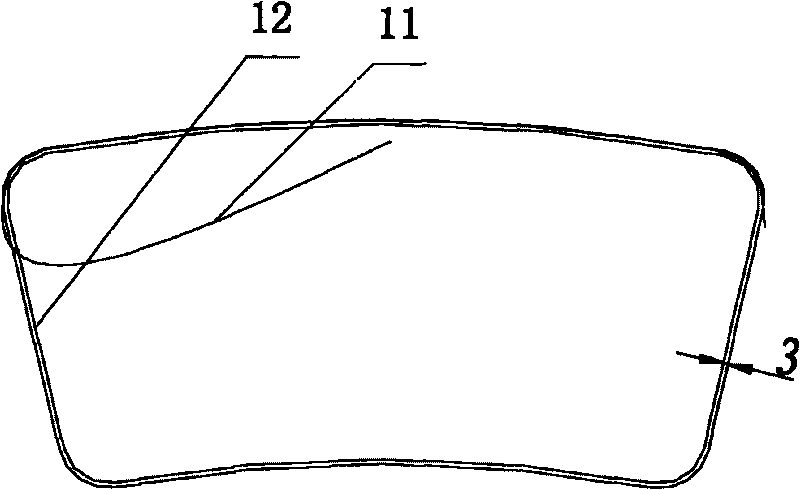

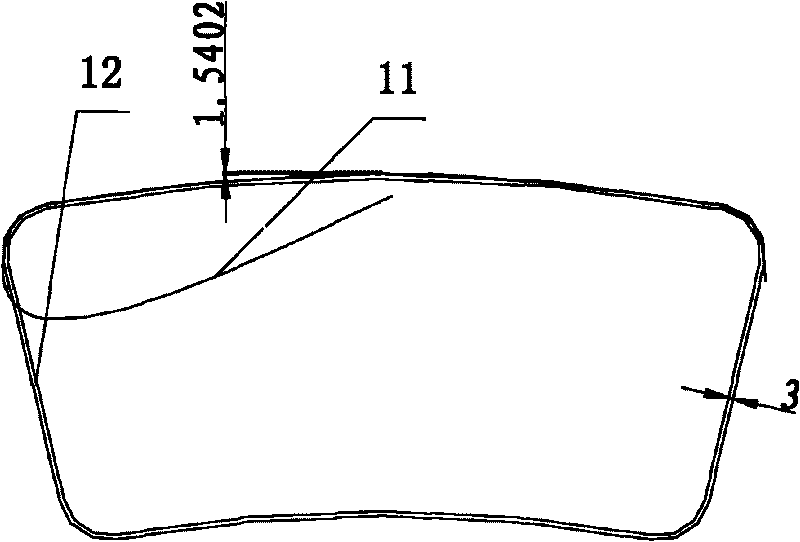

[0036] Described measuring bracket comprises base plate 3, and the two ends of base plate 3 are respectively provided with the round mouth s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com