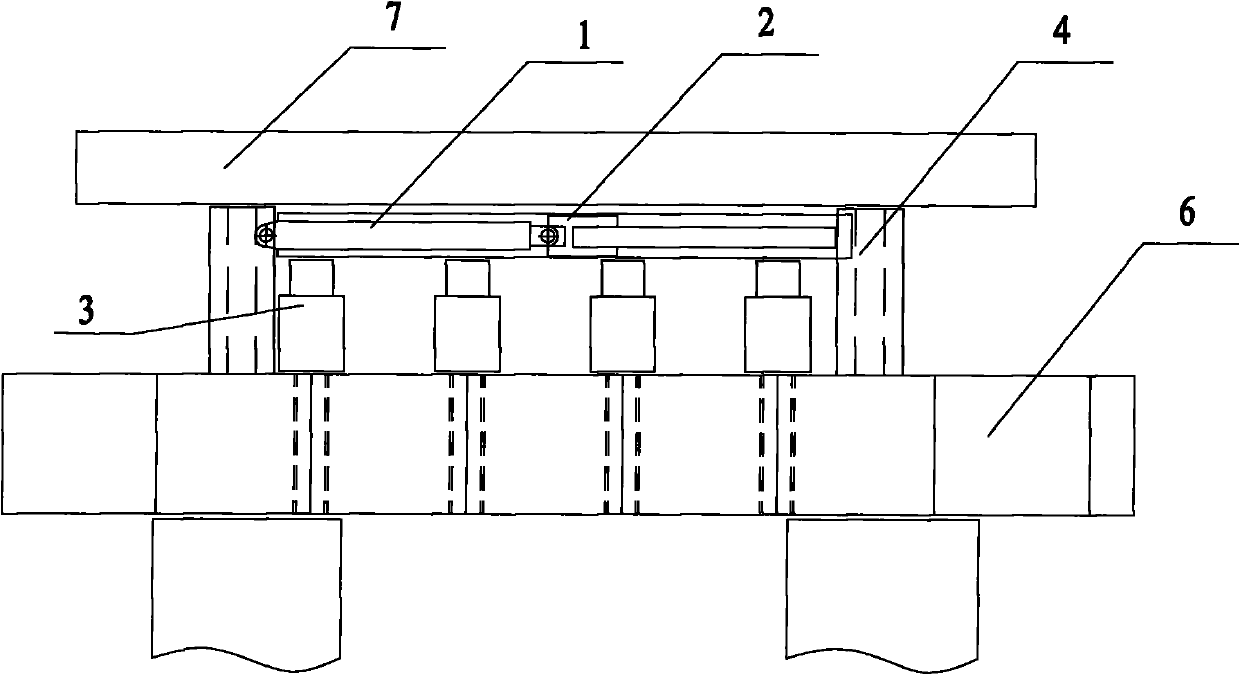

Jack-in erection equipment for bridge

A technology of jacking and equipment, applied in the direction of bridge construction, bridge erection/assembly bridge, etc., can solve the problems of overall technical complexity, complexity, and few large bridges, and achieve simplification of operation process, reduction of functions and quantities, and simplification of construction The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

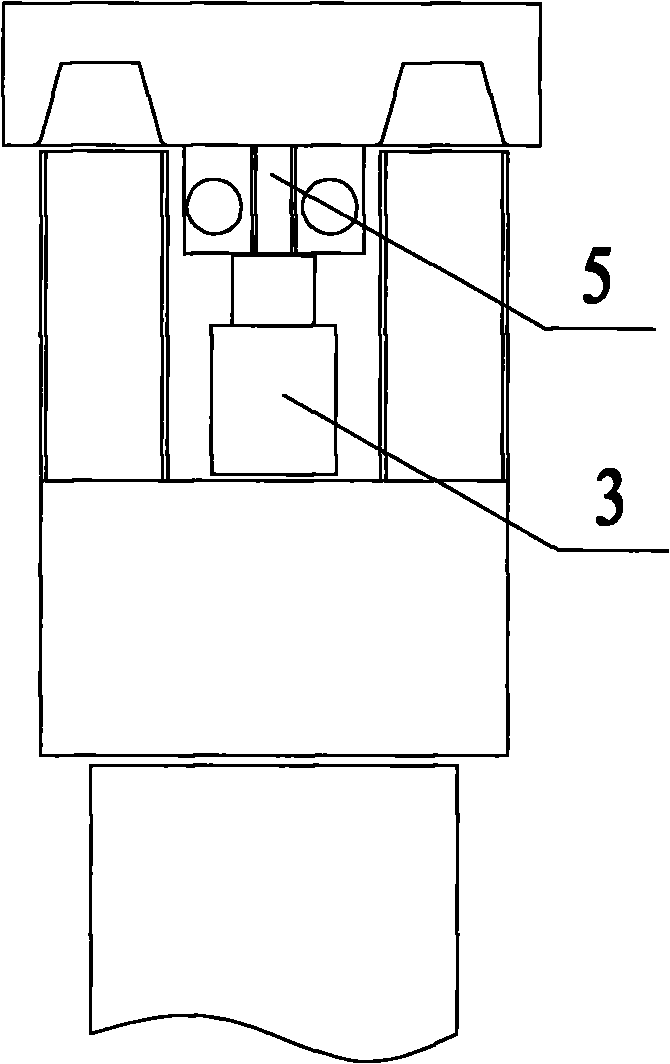

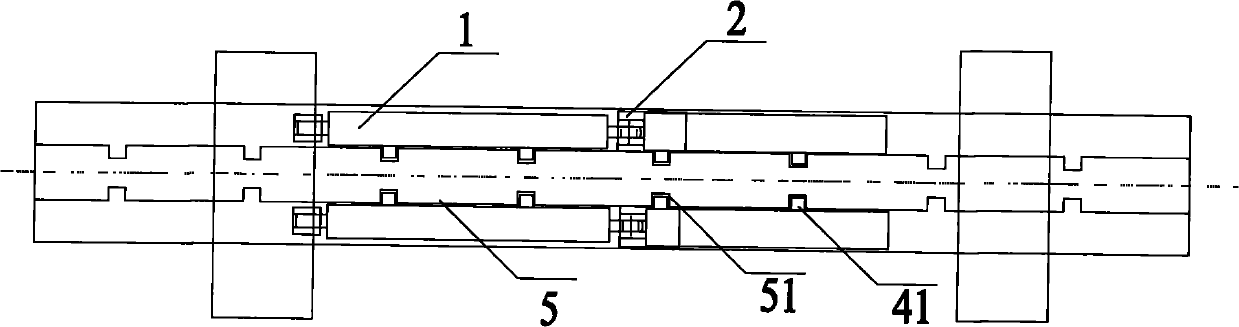

Method used

Image

Examples

Embodiment 1

[0031] A certain bridge has 30 piers, and the distance between the two piers is about 60m. Each pier is equipped with a jacking device of the present invention. The box girder is a steel box girder. , along the bridge to one temporary pier, one cable tower, along the river side along the bridge to six temporary piers,

[0032] First of all, the lateral offset during the work process is not greater than ±10mm. This requires the construction party to provide a guarantee that the sloshing offset of each pier is within the allowable value. Under the premise of ensuring this major premise, the following pushing process is carried out:

[0033] 1. Arrange 8 sets of jacking devices on the working temporary piers and pylons as required; connect all oil pipes, power lines and control lines.

[0034]2. Start the jacking device on the first temporary pier, and use the jacking device on the first temporary pier to push the guide beam to the elevation at that point synchronously; the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com