Degradable high polymer film-coated controlled release fertilizer

A high molecular polymer and controlled-release fertilizer technology, which is applied in the form of fertilizer, fertilizer mixture, fertilization device, etc., can solve the problem of general slow and controlled release effect, high molecular polymer coating material is difficult to degrade or the degradation time is long, and it is difficult to achieve Fertilizer nutrient release rate and other issues, to achieve a wide range of application prospects, conducive to the protection of the agricultural ecological environment, the effect of excellent explosion-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

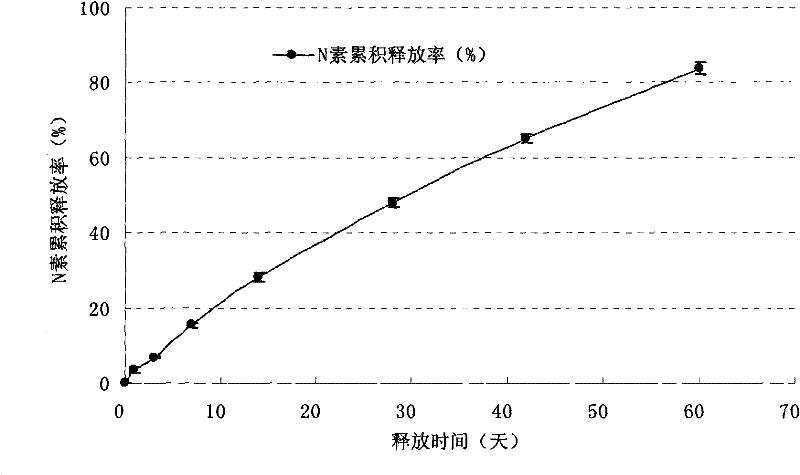

[0021] Example 1 Production of degradable coated controlled-release urea (44-0-0) with controlled release period of 2 months

[0022] Weigh 38kg of natural rubber and 2kg of EVA, heat to 110-130°C in 240kg of ethyl acetate and 360kg of dichloromethane mixture, stir and dissolve, and configure it as a spraying solution; 1000kg of large-grain urea (2.0-4.75mm) is fluidized The bed is preheated with hot air at 85-110°C, and the coating liquid is sprayed onto the surface of the suspended and fluidized urea particles through the nozzle. Under the action of the hot air, the solvent evaporates rapidly, and the coating material Wrapped on the surface of fertilizer granules to form a dry, smooth and dense film layer, through the continuous spraying of the coating liquid, until the coating process is completed, the coated controlled-release urea (44- 0-0), the volatilized solvent is recovered and recycled, and the product is packaged and put into storage.

Embodiment 2

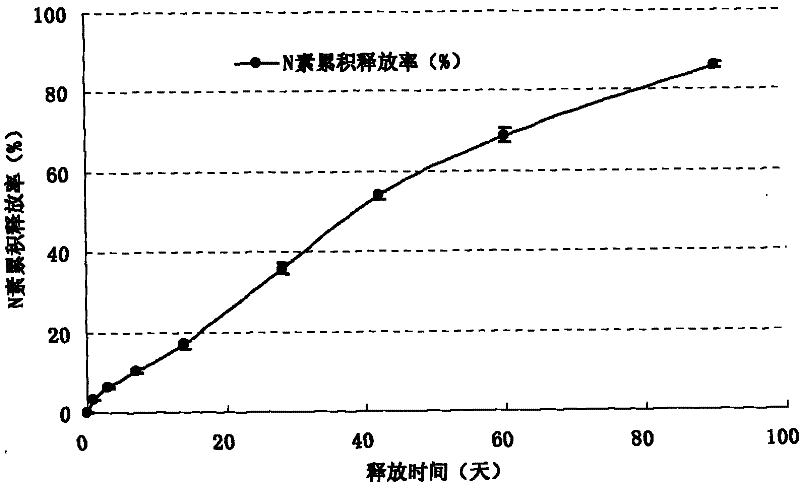

[0023] Example 2 Production of degradable coated controlled-release compound fertilizer (20-8-10) with controlled release period of 3 months

[0024] Weigh 45kg of natural rubber and 5kg of EVA, heat to 110-130°C in 450kg of ethyl acetate and 450kg of dichloromethane mixture, stir and dissolve, and configure it as a spray solution; 1000kg of large-grained urea (2.0-4.75mm) is fluidized The bed is preheated with hot air at 85-110°C, and the coating liquid is sprayed onto the surface of the suspended and fluidized urea particles through the nozzle. Under the action of the hot air, the solvent evaporates rapidly, and the coating material Wrapped on the surface of the fertilizer particles to form a dry, smooth and compact film layer, through continuous spraying of the coating liquid, until the coating process is completed, the coated controlled-release compound fertilizer (20 -8-10), the volatilized solvent is recovered and recycled, and the product is packaged and put into storag...

Embodiment 3

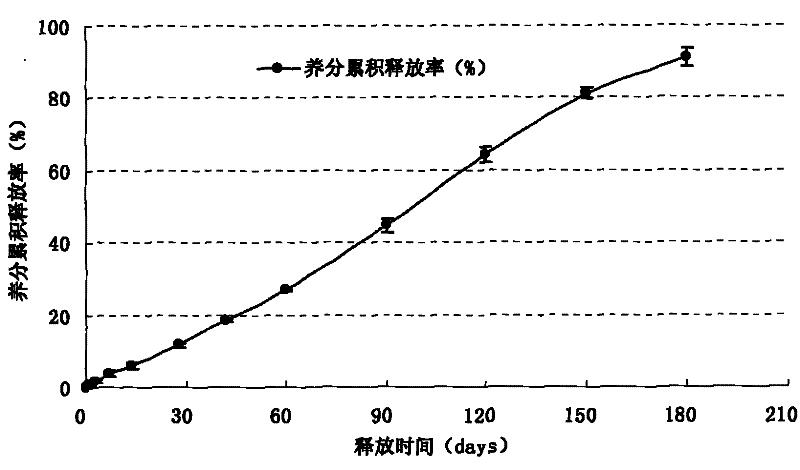

[0025] Example 3 Manufacture of degradable coated controlled-release urea (42-0-0) with controlled release period of 6 months

[0026] Weigh 63kg of natural rubber and 7kg of EVA, heat to 110-130°C in 630kg of ethyl acetate and 630kg of dichloromethane mixture, stir and dissolve, and configure it as a spray solution; 1000kg of large-grain urea (2.0-4.75mm) is fluidized The bed is preheated with hot air at 85-110°C, and the coating liquid is sprayed onto the surface of the suspended and fluidized urea particles through the nozzle. Under the action of the hot air, the solvent evaporates rapidly, and the coating material Wrapped on the surface of the fertilizer particles to form a dry, smooth and dense film layer, through continuous spraying of the coating liquid, until the coating process is completed, the coated controlled-release urea (42- 0-0), the volatilized solvent is recovered and recycled, and the product is packaged and put into storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com