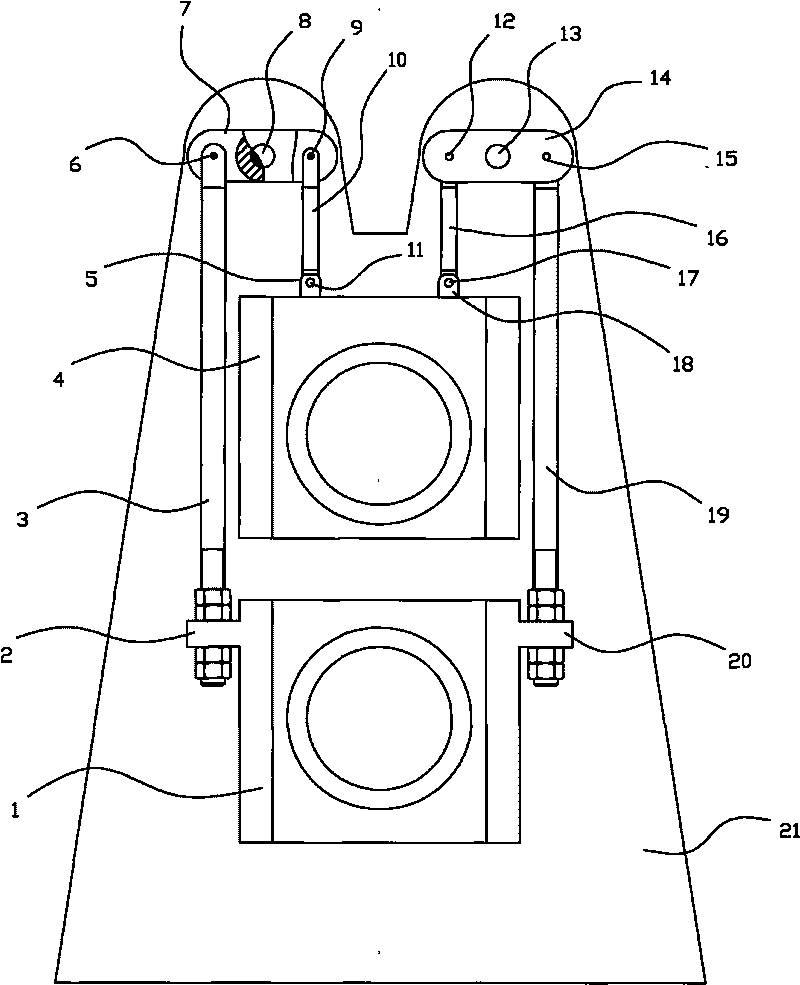

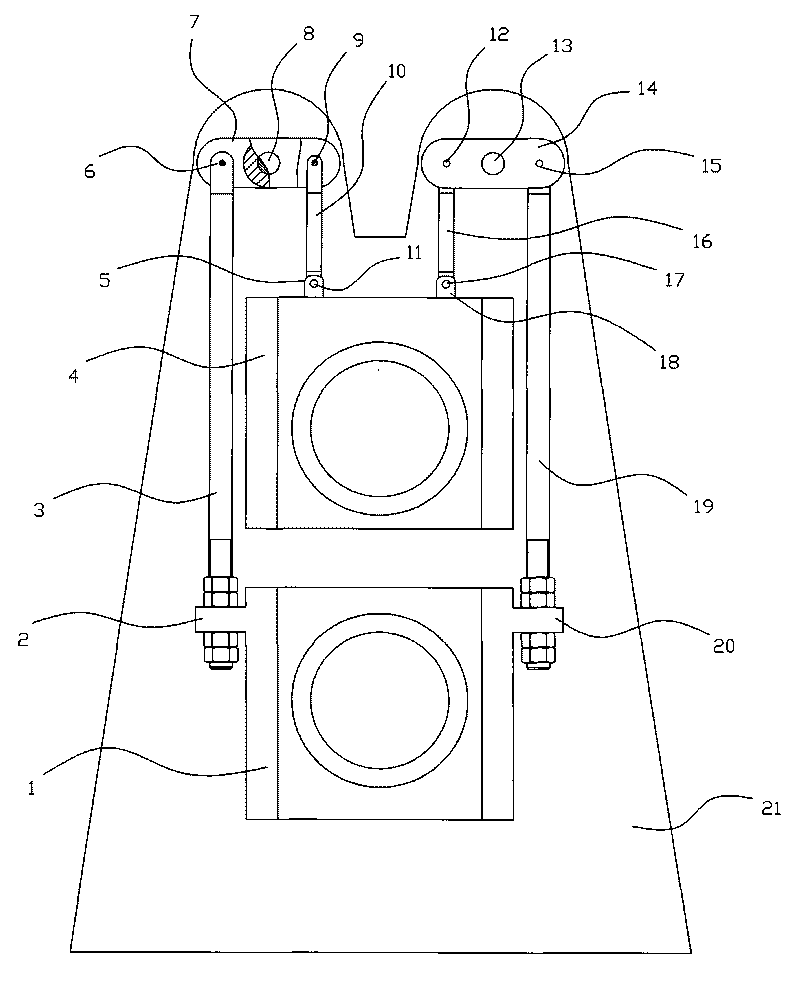

Balanced connection mechanism for finishing mill bracket

A technology of balanced connection and finishing mill, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve problems affecting rolling stability, large bracket vibration, stop production, etc., to achieve outstanding substantive Features, Effects of Preventing Changes in Roll Gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0009] It can be seen from the accompanying drawings that the bracket balance connection mechanism of the finishing mill in this program has a frame 21, an upper bracket 4 and a lower bracket 1, and the upper bracket 4 has an upper bracket left mounting ear 5 and an upper bracket Right mounting ear 18, lower bracket left mounting ear 2 and lower bracket right mounting ear 20 are arranged on lower bracket 1, left central axis 8 and right central axis 13 are arranged on frame 21 above upper bracket 4, and , the axis of the left central shaft 8 and the axis of the right central shaft 13 are on the same horizontal plane. This scheme is that the left lever 7 is housed on the left central axis 8, and the left lower link 3 is connected with the left lower link connecting shaft 6 on the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com