Contact type measuring method for precisely measuring position of bearing ferrule trench

A technology of contact measurement and bearing ring, which is applied in the direction of measuring devices, electrical devices, instruments, etc., can solve the problems of difficult to achieve high-precision measurement of bearing rings and large errors, so as to improve the accuracy of measurement and meet the requirements of precision assembly desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

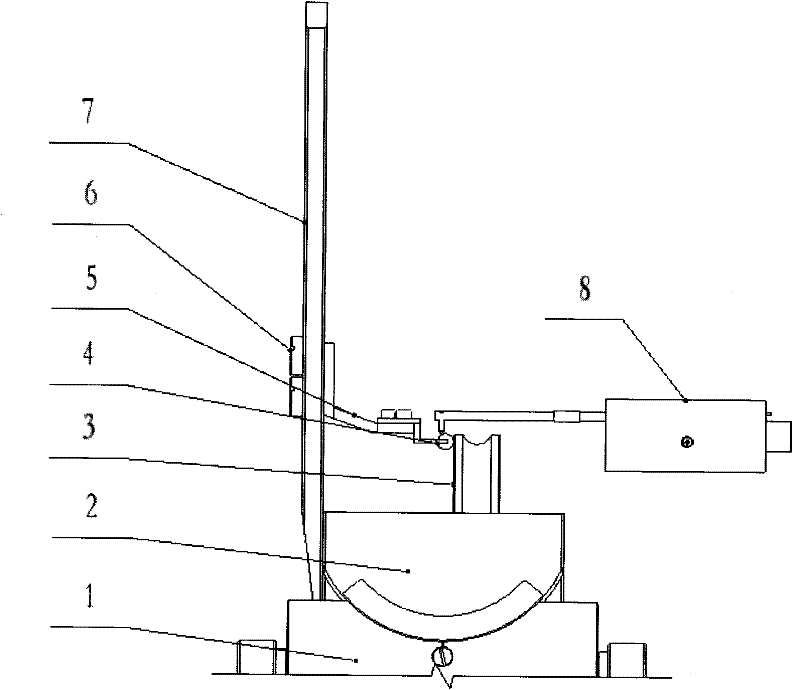

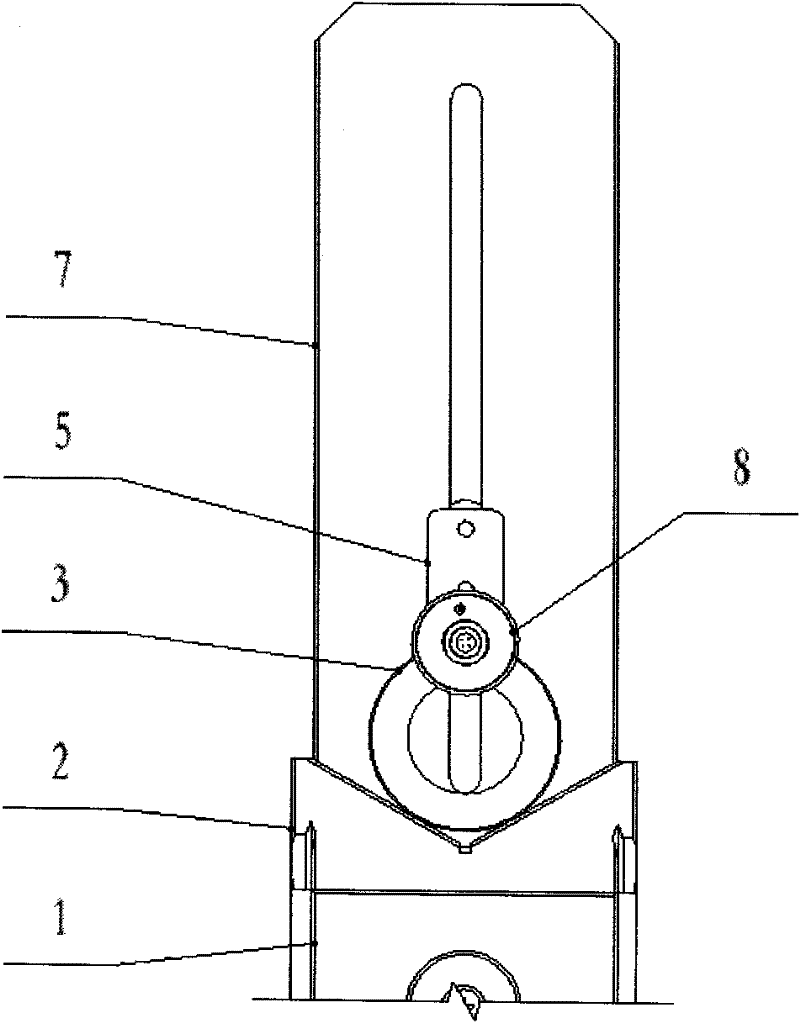

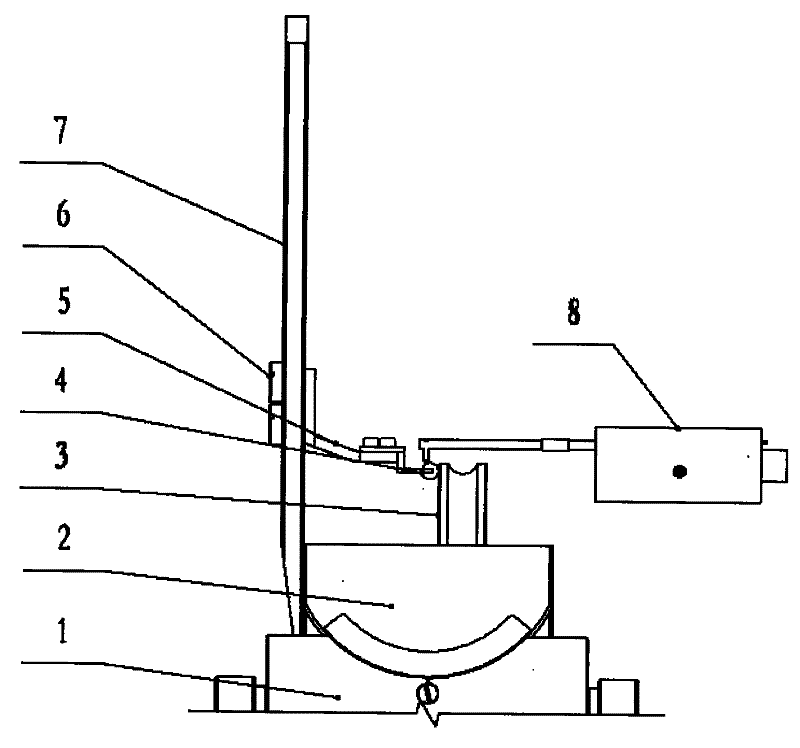

[0016] The measuring device used to realize the contact measuring method of precision measuring bearing ring groove position of the present invention consists of a workbench 1, a V-shaped groove table 2, a standard ball 4, a groove position measuring bracket 5, a locking screw 6, a baffle plate 7 and an inductance The sensor 7 constitutes.

[0017] combine Figure 1-2 Firstly, place a workbench 1 with a semi-arc groove on the profiler, and set a V-shaped groove table 2 on the upper end of the semi-arc groove workbench. The V-shaped groove table 2 can rotate along the semi-arc groove of the workbench 1. It can move horizontally along the length direction of the semi-arc groove of the workbench. A baffle 7 is installed at the left end of the V-shaped groove table 2. There is a straight groove in the middle of the baffle 7 in the vertical direction. The vertical center line of the straight groove of the baffle plate is aligned with the V-shaped groove table. The center line of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com