Full-height railway shielding door upright column system

A screen door and column technology, applied in railway car body parts, stations, roads and other directions, can solve the problems of inconvenience, affect the use of subway screen doors, and not ideal, achieve convenient installation, meet structural stress requirements, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

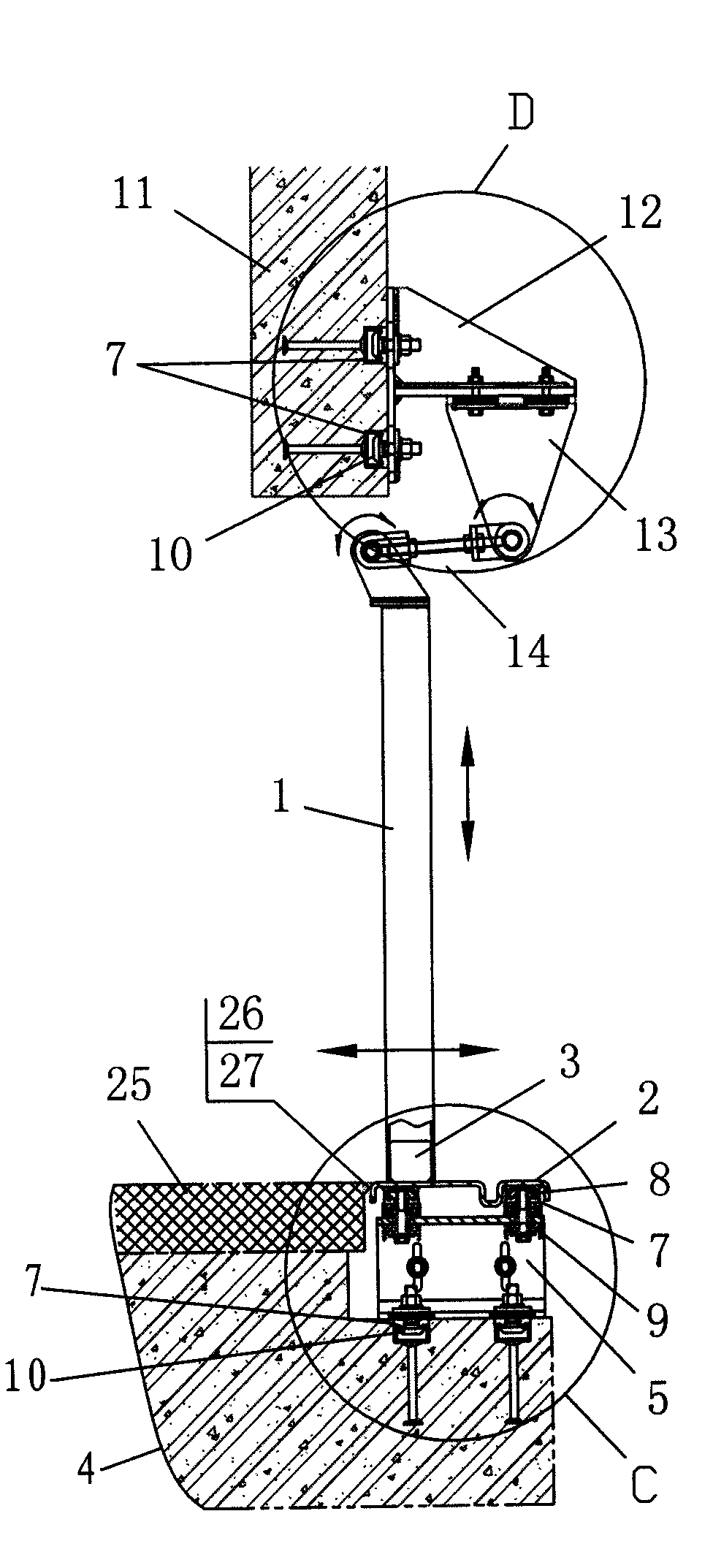

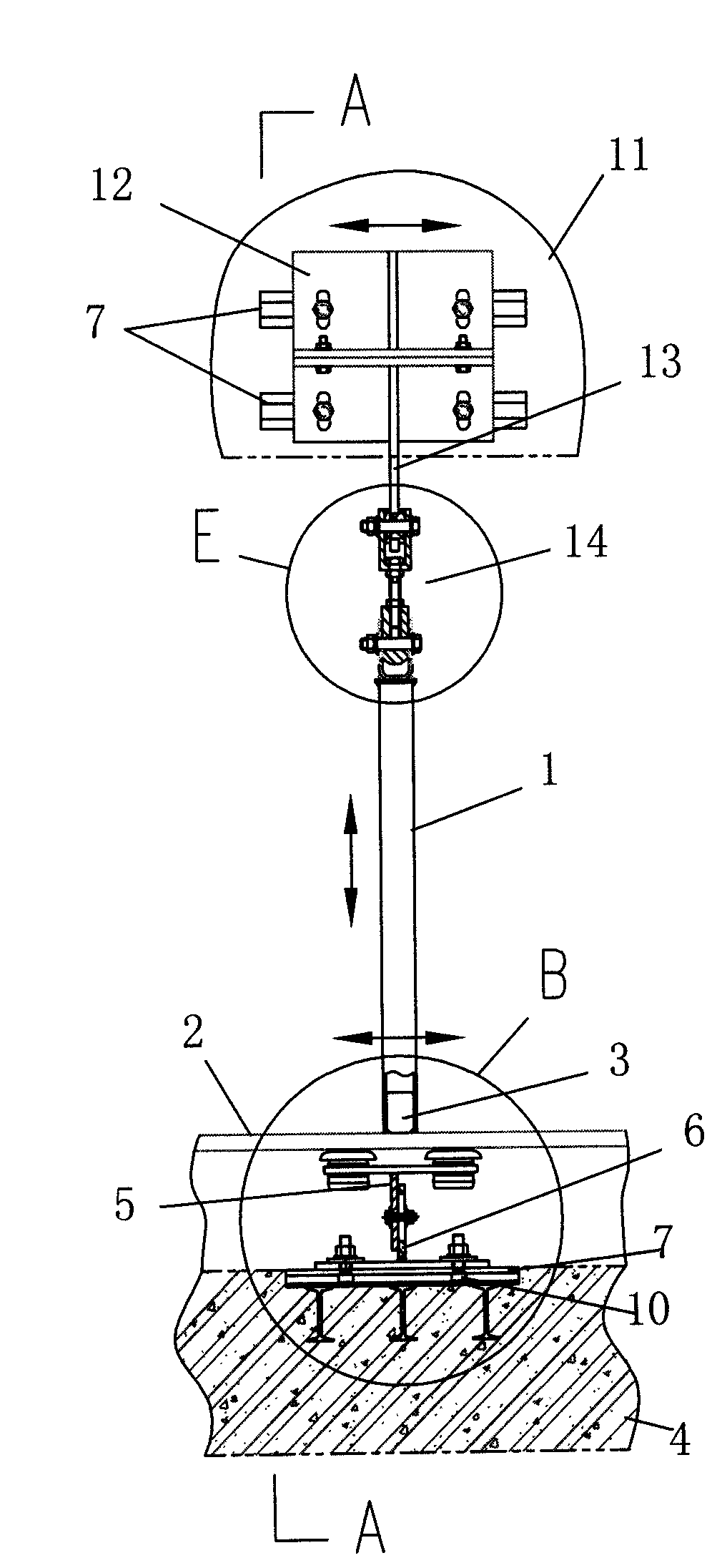

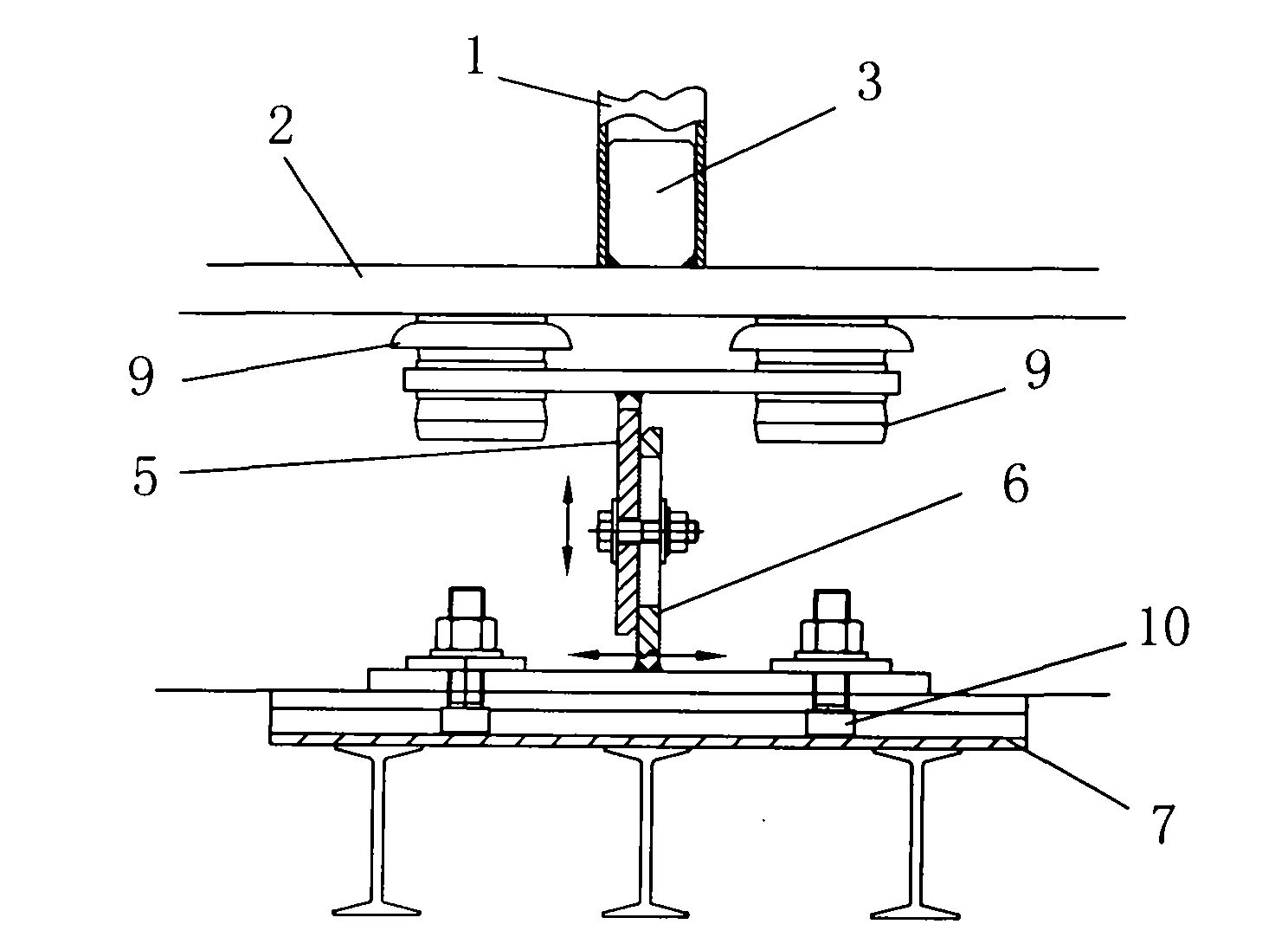

[0018] figure 1 , figure 2 The basic structure of the preferred embodiment of the present invention is shown. The full-height subway screen door column system includes a steel hollow column 1, an upper support system of the column and a lower support system of the column. The lower supporting system includes: a threshold 2 , a socket block 3 arranged on the upper surface of the threshold and connected to the lower end of the column, and a support assembly arranged between the threshold 2 and the civil structure 4 below. refer to image 3 , the bearing assembly includes upper and lower bearings 5 and 6 connected by bolts, vertical bolt slots are arranged on the vertical plate of the lower bearing 6, and the contact surfaces of the vertical plates of the upper and lower bearings are along the vertical There are mutually meshing teeth in the vertical direction, so that the upper and lower supports can move vertically with each other. refer to Figure 4 , the lower surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com