Bamboo stick pyrograph machine

A bamboo stick hot stamping machine, bamboo stick technology, applied in printing machines, rotary printing machines, machines for branding, etc., can solve the problems of invisible strokes, high processing difficulty, high mold processing costs, and achieve rich patterns. Colorful, precise and beautiful hot stamping, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

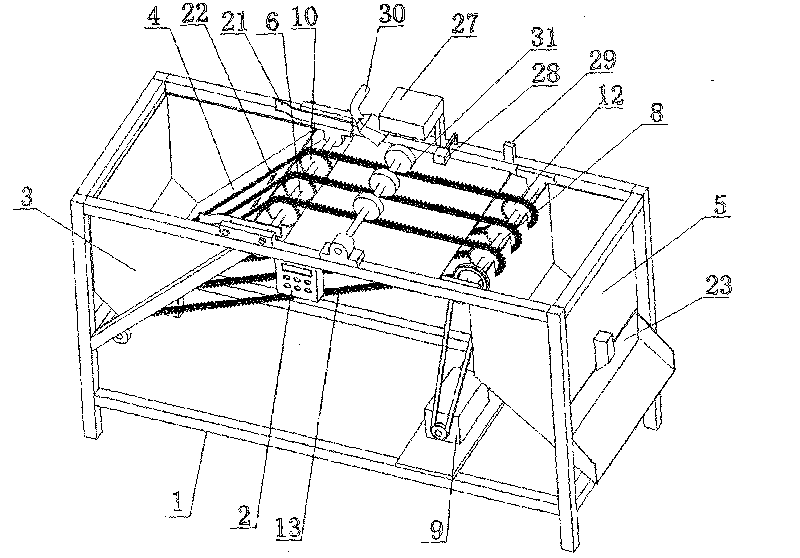

[0022] Embodiment 1: as figure 1 , figure 2 and Figure 4 Shown, a kind of bamboo stick embossing machine, it comprises frame 1, electric control mechanism 2, the two ends of frame 1 are provided with feed hopper 3 and discharge hopper 5, the inner side of described feed hopper 3 is 45 Angle of the slope plane 4, the upper and lower parts of the slope plane 4 are respectively installed with the upper chain shaft 6 and the lower chain shaft 7, and the upper opening of the inner side of the discharge hopper 5 is installed at the same height position as the upper chain shaft 6 driven by the motor 9. Drive sprocket 8, upper sprocket 10, lower sprocket 11 and transmission sprocket 12 are respectively installed on two or three planes of upper chain shaft 6, lower chain shaft 7 and drive chain shaft 8, and two or three On the upper sprocket 10 of the plane, the lower sprocket 11 and the drive sprocket 12, the transmission chain 13 is installed respectively, and there are two protr...

Embodiment 2

[0023] Embodiment 2: as image 3 , Figure 4 Shown, a kind of bamboo stick embossing machine, it comprises frame 1, electric control mechanism 2, the two ends of frame 1 are provided with feed hopper 3 and discharge hopper 5, the inner side of described feed hopper 3 is 45 Angle of the slope plane 4, the upper and lower parts of the slope plane 4 are respectively installed with the upper chain shaft 6 and the lower chain shaft 7, and the upper opening of the inner side of the discharge hopper 5 is installed at the same height position as the upper chain shaft 6 driven by the motor 9. Drive sprocket 8, upper sprocket 10, lower sprocket 11 and transmission sprocket 12 are respectively installed on two or three planes of upper chain shaft 6, lower chain shaft 7 and drive chain shaft 8, and two or three On the upper sprocket 10 of the plane, the lower sprocket 11 and the drive sprocket 12, the transmission chain 13 is installed respectively, and there are two protrusions on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com