Vitrified tile weave fabric process

A vitrified brick and textured technology, applied in the direction of manufacturing tools, supply devices, etc., can solve the problem of not being able to well reflect the natural and smooth effect of natural stone, and achieve a realistic imitation marble effect, a wide range of designs, and controllability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

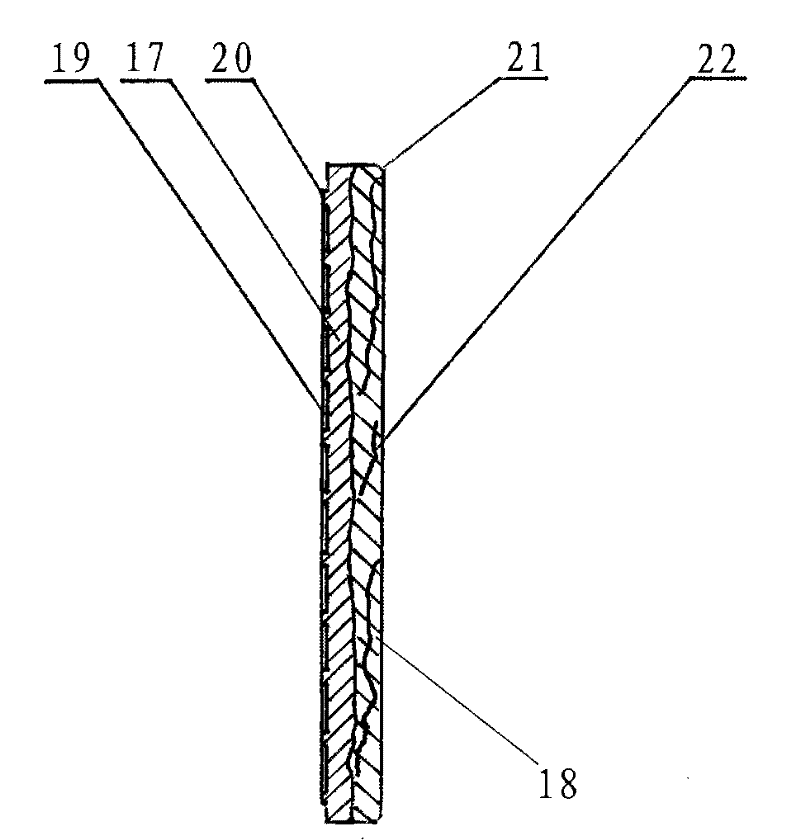

[0019] Such as figure 1 Shown; A vitrified brick weave fabric process, the process includes fabric delivery, thread material delivery and stockpiling, the fabric delivery is to place the micro-powder fabric in the fabric bucket 5, through the fabric drum below the fabric bucket 5 6 Rotate and drop the material into the fabric storage hopper 4, the outlet below the storage hopper 4 is the conveyor belt 2, and the conveyor belt 2 rotates to evenly spread the micro-powder fabric on the conveyor belt 2, and the front and bottom of the conveyor belt 2 are suspended in the air. Conveying is to rotate the line material 8 from the line unloading drum 9 and drop it onto the baffle plate 10 and the vibrating sieve 11. The vibrating sieve 11 sprinkles the line material thinly and evenly on the woven pattern flat belt 12 rotating below. Also drop on the weave pattern flat belt 12 with block during support, there will be line material at the middle interval, the blanking place of described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com