Method for automatically cleaning net cage underwater

An automatic cleaning and net cage technology, which is applied in the floating raft net cage breeding at sea and in the agricultural field, can solve the problems of pollution in the sea area, increase labor costs, large consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

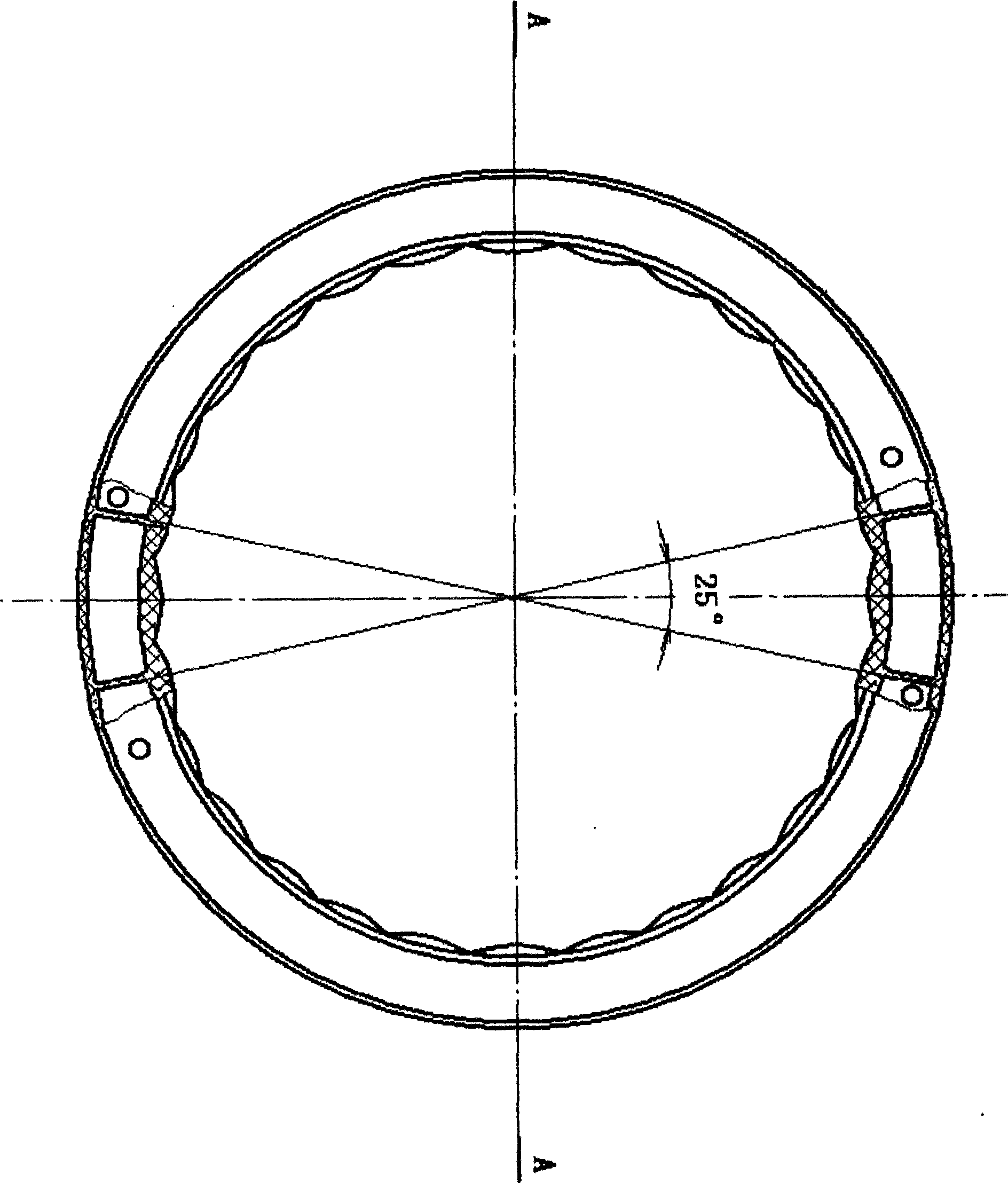

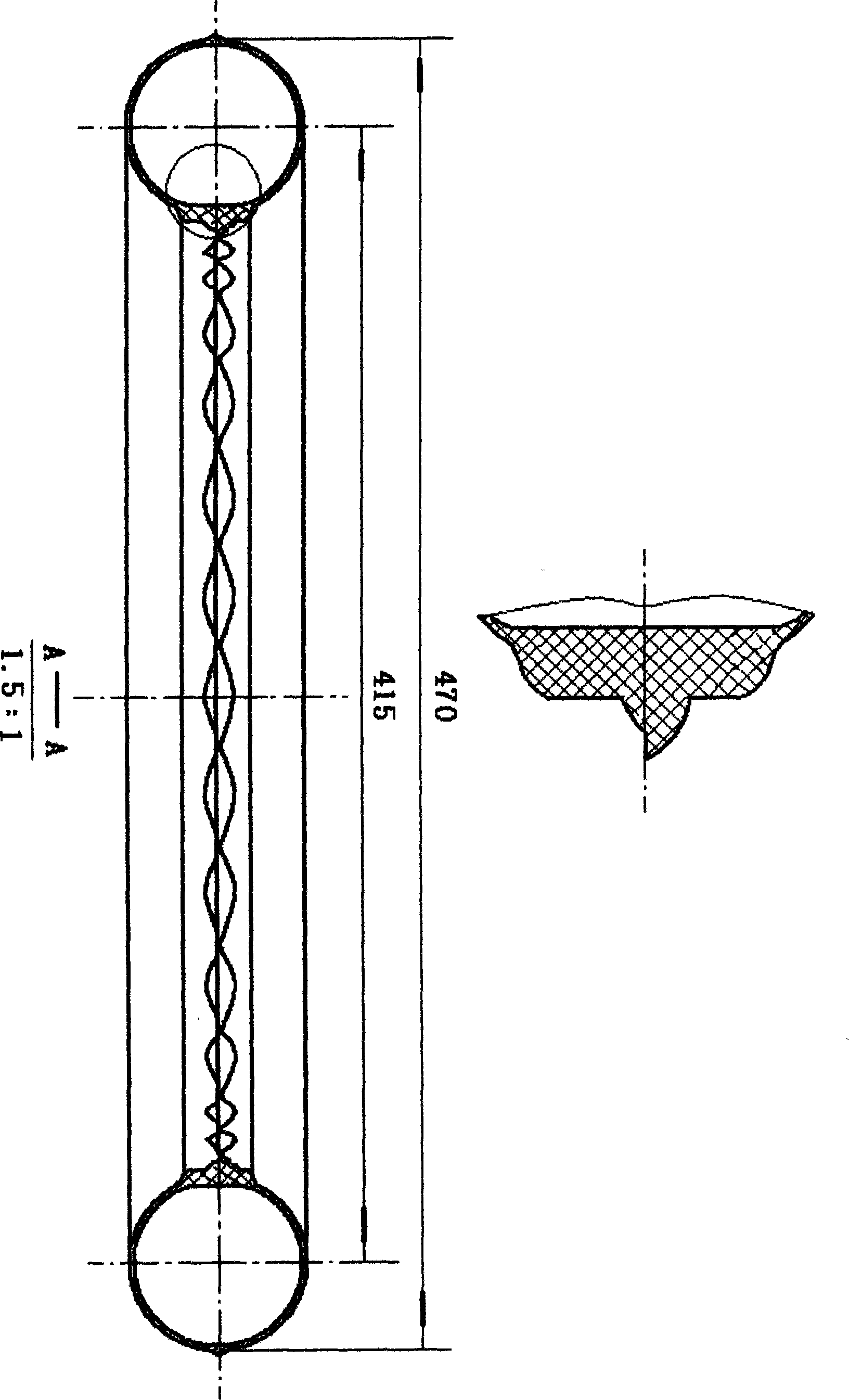

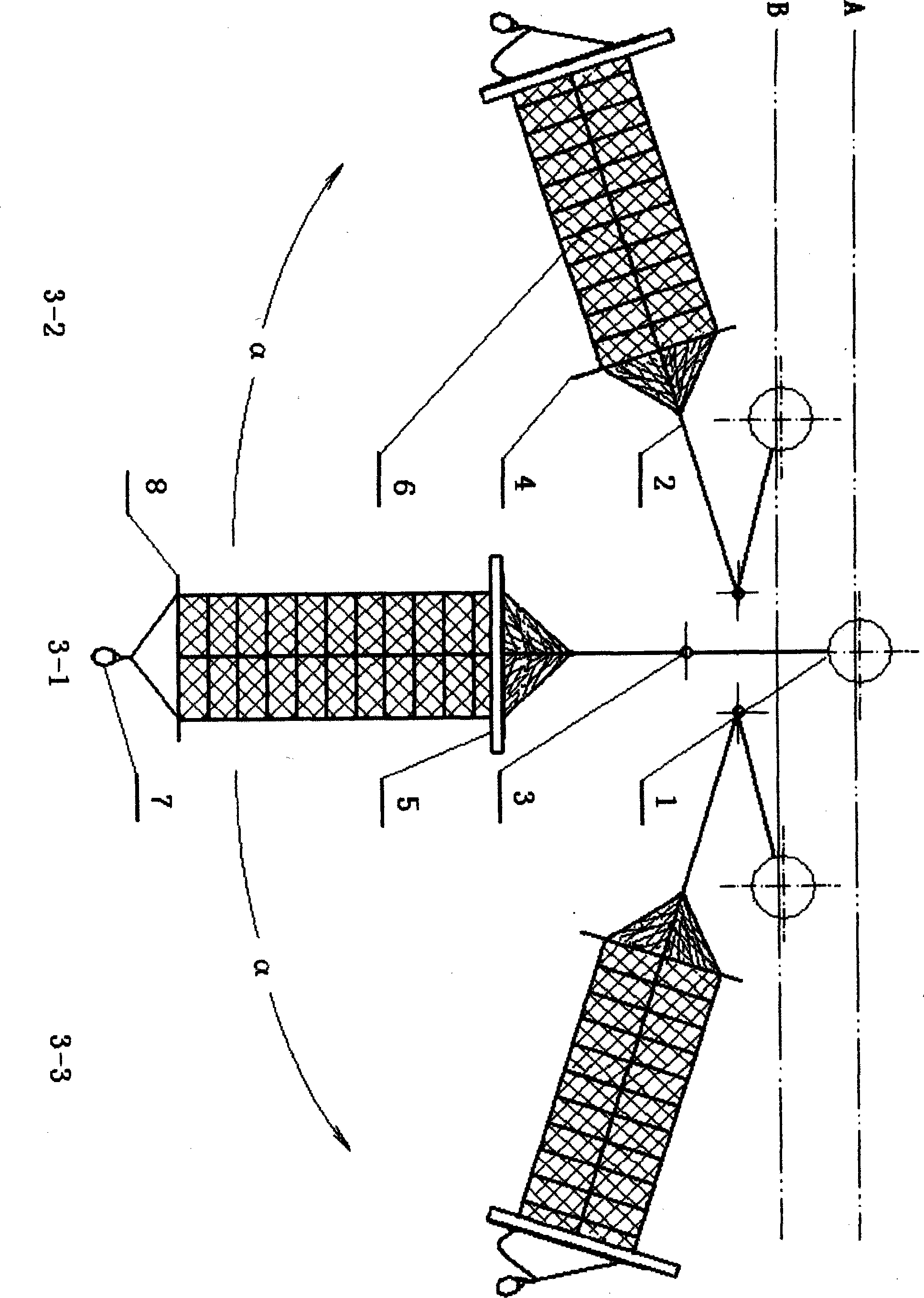

[0012] To control the overall specific gravity of the annular hollow float net scraper, divide the hollow circle part of the annular hollow float net scraper into two groups of four equal float chambers, (such as figure 1 ) partially cut away are two small float chambers of equal size and mutual symmetry. Drill holes in the upper and lower positions of the two large float chambers scraped by the circular hollow float net (such as figure 1 There are four small round holes in it), so that it can be naturally injected with seawater and become a water storage chamber. The use of this structure can effectively improve the overall momentum of the ring-shaped hollow float net scraper, and can save materials.

[0013] The shape of the net scraper is designed as two partial spherical crowns of different sizes, and the bottom-to-bottom parts are overlapped together. The outer contour of the cross-section is composed of two staggered arcs of different lengths and a short straight line. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com