Built-in permanent magnet dual-side flat plate type linear motor

A linear motor and permanent magnet technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of small air gap magnetic density and low thrust density, and achieve higher magnetic density, higher thrust density, and increased maximum torque. The effect of output ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

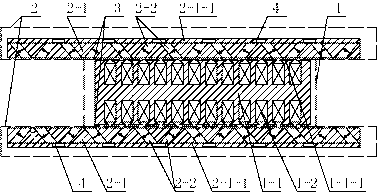

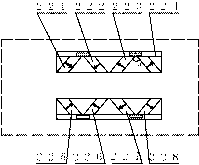

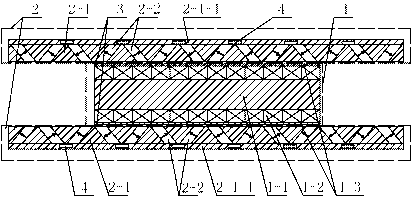

[0011] Specific implementation mode one: the following combination figure 1 and figure 2 Describe this embodiment. This embodiment includes a primary 1 and a secondary 2. The secondary 2 includes two flat-shaped excitation components. The primary 1 is located in the middle of the two flat-shaped excitation components of the secondary 2. Each flat-shaped excitation component There is an air gap 3 between the inner surface and the outer surface of one side of the primary 1; the structures of the two flat-shaped excitation components are mirror-symmetrical;

[0012] Each flat-shaped excitation part is composed of a secondary iron core 2-1 and a plurality of permanent magnets 2-2, and each secondary iron core 2-1 is provided with multiple pairs of slots on the side of the air gap 3, and each slot has a permanent magnet 2-2, and the permanent magnet 2-2 is closely matched with the slot, and the two permanent magnets in each pair of slots and the iron core in the middle form a ma...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1 This embodiment is described. The difference between this embodiment and Embodiment 1 is that the material of the back yoke 2 - 1 - 1 of the permanent magnet on the secondary core 2 - 1 is a non-magnetic material. Other components and connections are the same as those in Embodiment 1.

[0021] In this embodiment, the secondary iron core part between the permanent magnets 2-2 adopts a magnetically conductive material, and the back yoke 2-1-1 of the permanent magnet uses a non-magnetically conductive material, which can make the permanent magnet 2-2 leak magnetic circuit reluctance Increase, thereby increasing the magnetic flux of the main magnetic circuit.

specific Embodiment approach 3

[0022] Specific implementation mode three: combination figure 1 Describe this embodiment, the difference between this embodiment and Embodiment 1 or 2 is that there are multiple air slots 4 on the back yoke 2-1-1 of the permanent magnet on the secondary core 2-1, and each air slot 4 The position corresponds to the position of a pair of slots on the secondary core 2-1, and the symmetry line of each pair of slots coincides with the center line of the corresponding air slot 4. Other compositions and connections are the same as those in the first or second embodiment.

[0023] In this embodiment, a plurality of air slots 4 are arranged on the back yoke 2-1-1 of the permanent magnet, and each air slot 4 increases the leakage reluctance between each pair of permanent magnets 2-2 by utilizing the high reluctance characteristic of air , to reduce flux leakage and increase the air gap flux density of the motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com