Heat-sensible composition for positive thermosensitive CTP plate without preheating and plate-making method by using same

A composition and heat-sensitive technology, which can be used in the photoplate-making process of patterned surface, photosensitive materials used in photomechanical equipment, printing plate preparation, etc., can solve the problem of insufficient solvent resistance, inability to completely decompose ether compounds, active ethers, etc. Problems such as large molecular weight of compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

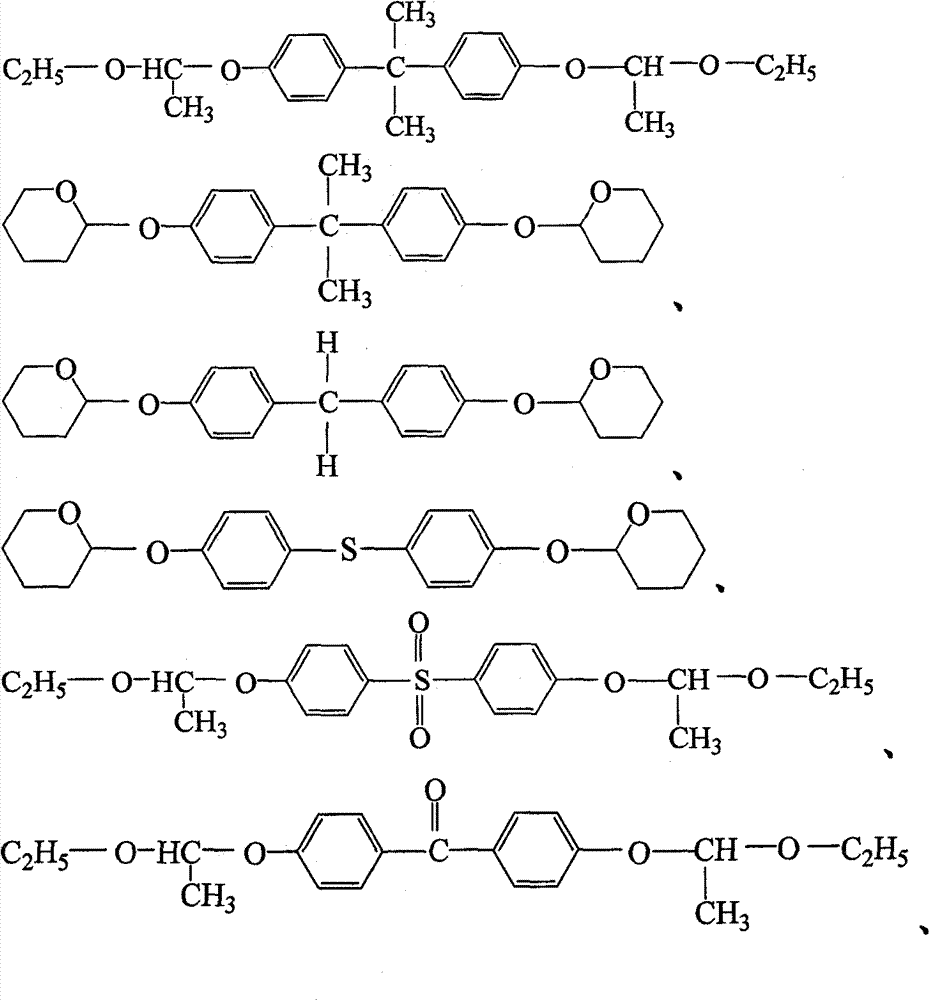

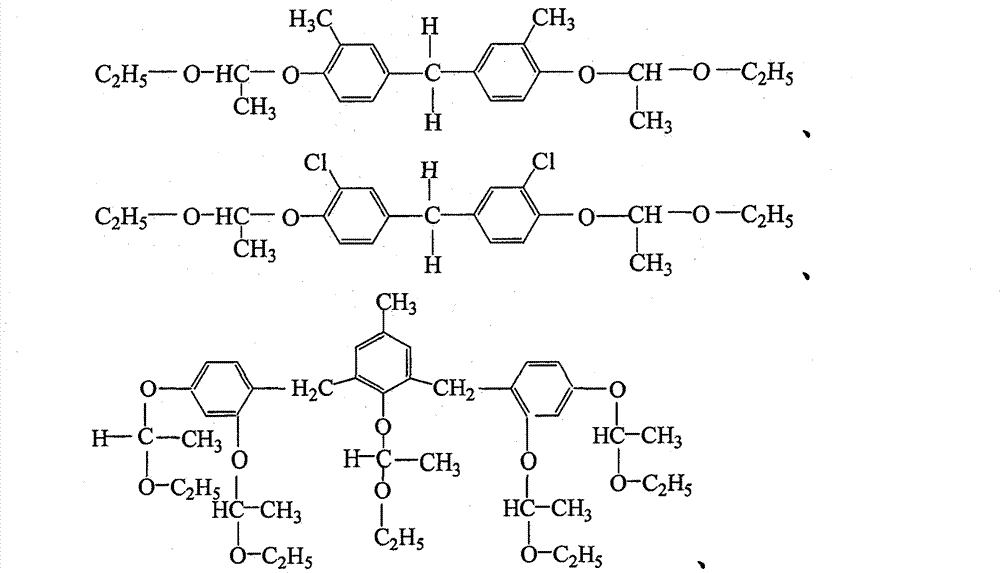

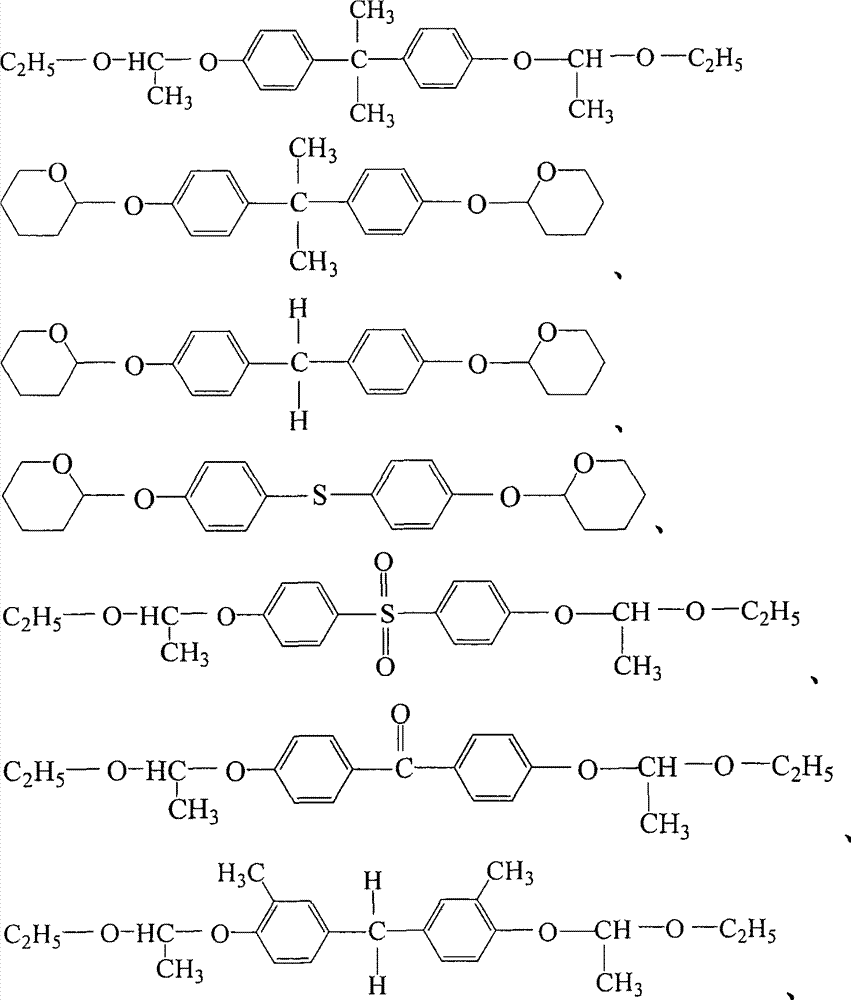

Method used

Image

Examples

Embodiment 1~6

[0082] The plate base used in Examples 1-6 is obtained by using the Positive PS plate production line, and the 0.3mm aluminum plate is obtained through mechanical roughening → electrolytic roughening → anodic oxidation → sealing treatment → washing and drying, and its R a The value is 0.58μm, R h (R z ) value is 2.8μm, and the amount of oxide film is 3.0g / m 2 . The sealing fluid used was prepared by dissolving 100 kg of potassium dihydrogen phosphate and 1.4 kg of potassium fluoride in 1 cubic meter of deionized water. The length of the sealing groove is 3 meters, and the temperature of the sealing liquid is 60°C. The treated plate base is directly sent to the extrusion coating section for coating, and the coating head adopts a closed extrusion coating head. By controlling the flow rate of the metering pump and the gap width of the extrusion nozzle of the coating head, the coating amount (in terms of solid content) is controlled at 1.6-1.8g / m 2 . After being leveled by t...

Embodiment 7

[0084] Change 50% of the potassium dihydrogen phosphate in the sealing solution of Examples 1 to 5 to monosodium tartrate of the same weight, while 50% of the potassium dihydrogen phosphate and all potassium fluoride remain; Base treatment, plate coating and drying process are the same as in Example 1. A non-preheated positive working thermal CTP plate WLTP-7 was obtained.

Embodiment 8

[0086] Replace 50% of the potassium dihydrogen phosphate in the sealing solution of Examples 1 to 5 with an equivalent amount of sodium silicate, while 50% of the potassium dihydrogen phosphate and all of the potassium fluoride are retained; the composition of the thermosensitive composition and the substrate Treatment, plate coating and drying process are the same as in Example 2. A non-preheated positive working thermal CTP plate WLTP-8 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com