Method for detecting output current of inverting welding machine

A technology of output current detection and inverter welding machine, applied in the direction of measuring current/voltage, measuring device, measuring electrical variables, etc., can solve the problems of high cost, low cost and complex detection circuit of Hall current sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

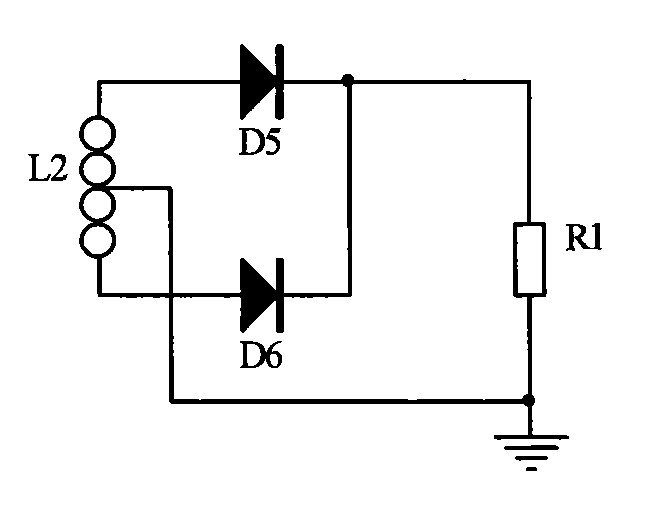

[0009] According to attached figure 1 The circuit configuration of the present invention will be described. The current transformer L1 is placed on the primary (or secondary) of the main transformer, detects the primary (or secondary) current of the transformer, and rectifies the current sampled by L1 through a bridge rectifier circuit composed of rectifier diodes D1, D2, D3 and D4 After being sampled by the resistor R1, the voltage is divided by the resistors R2 and R3, and the voltage value of R3 is proportional to the primary current of the main transformer. The noninverting input terminal (pin 4) of the voltage comparator U1A is connected to R3, and the input terminal (pin 5) of the inverting terminal is connected to the output resistor R6. When the voltage of R3 is higher than the voltage of resistor R6, the output terminal (pin 2) of the voltage comparator U1A will have a low level to turn on Q1, so that the voltage source VCC charges the filter capacitor C1 through R5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com