Method for testing maximum compacted density and peel strength of lithium cell pole piece

A technology of compaction density and peel strength, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve the problems of separation between experiment and production and actual production situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

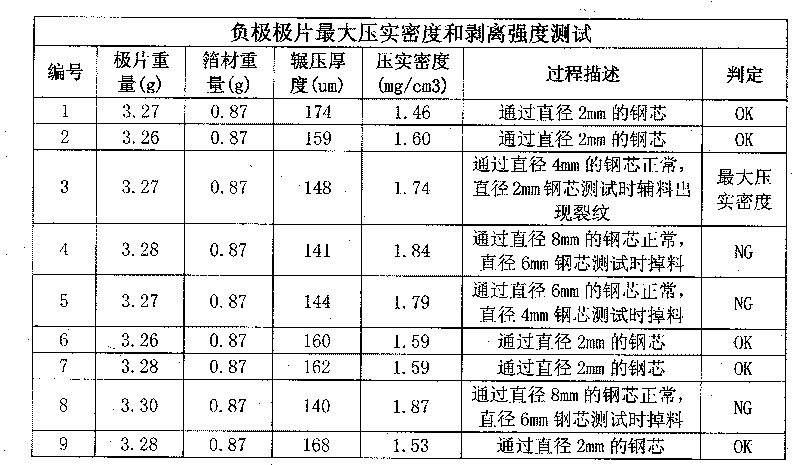

[0019] During the production process of cylindrical lithium batteries, the winding of the pole piece may cause cracks or peeling off of the coating of the active material (even if the lithium battery has charging ability) on the pole piece, so the pole piece needs to be cleaned before being put into lithium battery production. Test to see if it is suitable for making lithium batteries.

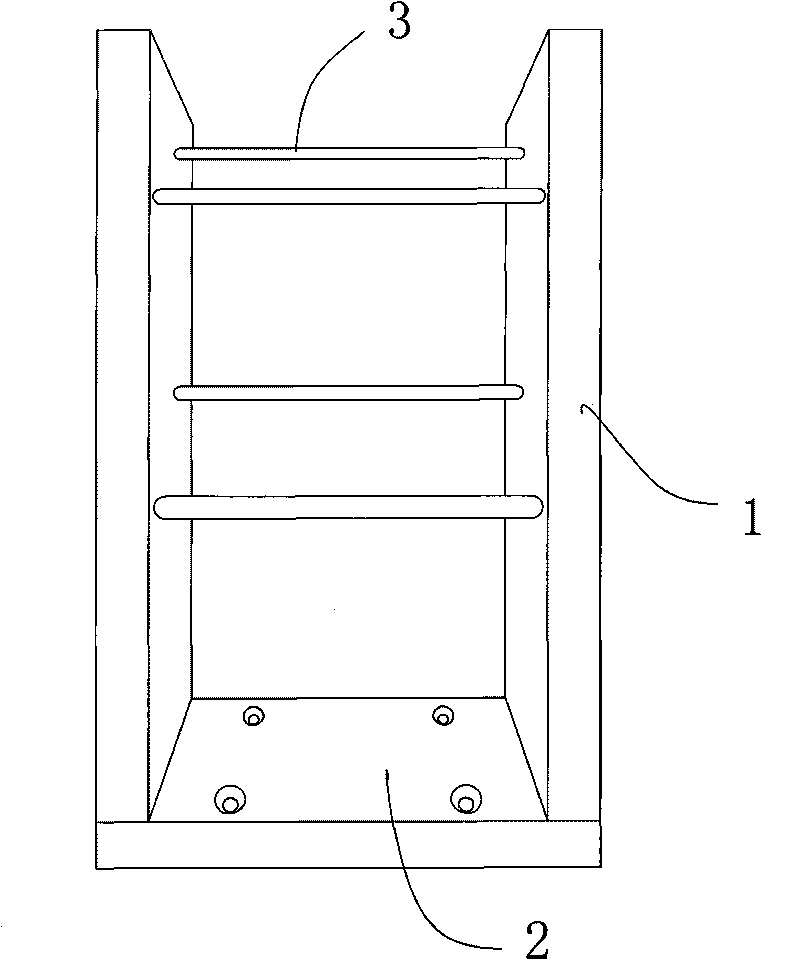

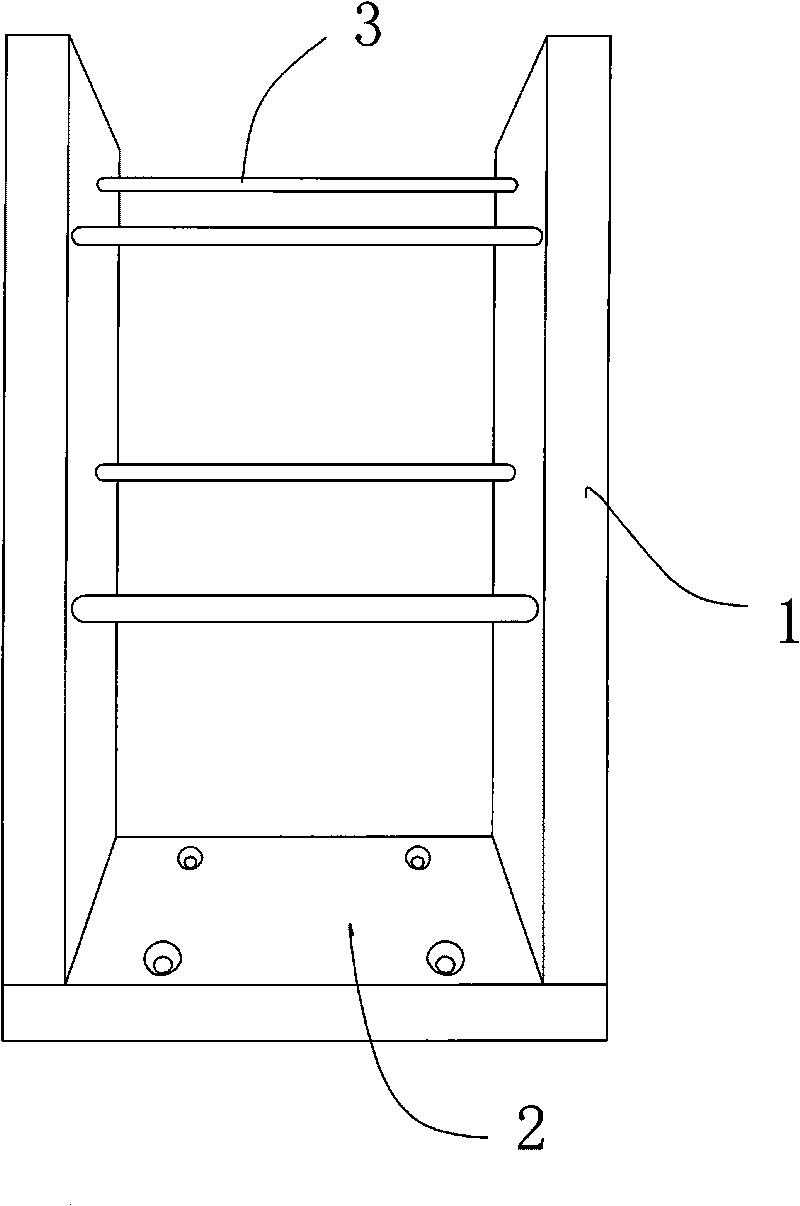

[0020] The invention relates to a method for testing the maximum compaction density and peel strength of a lithium battery pole piece. During the test, the test pole piece is surrounded on a cylindrical column to simulate the possible bending state of the pole piece during the lithium battery production process.

[0021] The compaction density is a parameter of the pole piece, and the calculation formula is:

[0022] Compacted density = surface density / (electrode rolling thickness - current collector thickness)

[0023] It can reflect the amount of active material in the unit volume of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com