Fine opener with under screen and card clothing

A technology of leaking bottom and card clothing, which is applied to fiber opening and cleaning machines, tooth-shaped tools, etc., can solve problems such as unsatisfactory production efficiency, improve opening and carding effect, improve conveying speed, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

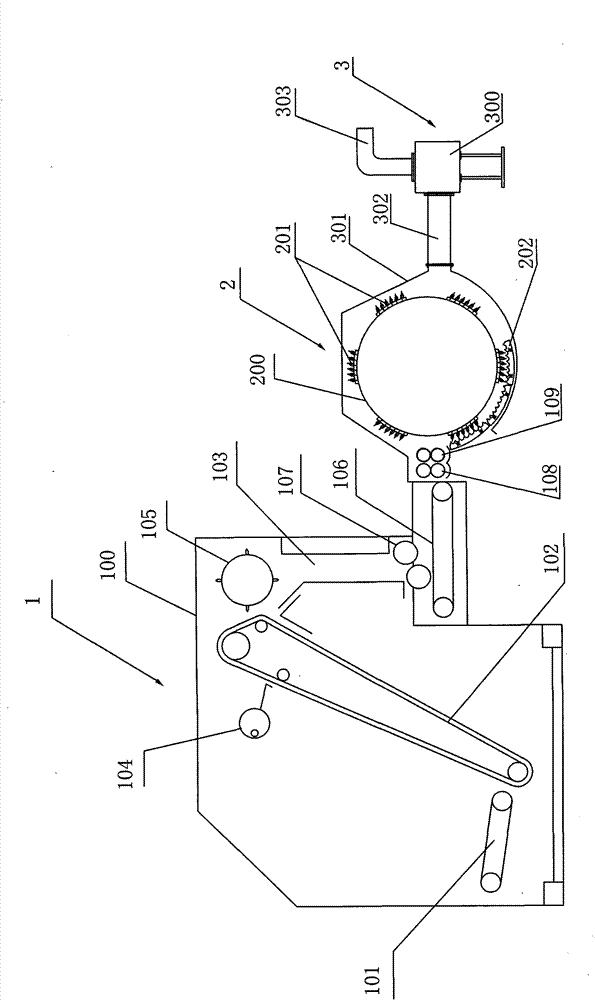

[0013] Referring to the accompanying drawings, a fine opener with card clothing with leakage bottom includes a feeding mechanism 1 , an opening and carding mechanism 2 and an opening fiber output mechanism 3 . The technical content not mentioned in the present invention can be implemented entirely by adopting or referring to the existing technical methods.

[0014] The above-mentioned feeding mechanism 1 includes a feeding bin 100, a small oblique curtain 101 at the bottom with a high front and a low back is arranged in the front part, a large oblique curtain 102 in the middle part with a high front bottom and a rear is arranged in the middle, and a rear part is provided with a The volume box 103, the bottom small slanted curtain 101 and the middle large slanted curtain 102 are connected at the lower part of the central large slanted curtain 102, and an equalizing rake 104 is arranged in front of and above the middle of the large slanted curtain 102. There is a stripping beate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com