Test model clay for simulating IV-class surrounding rock and method for preparing same

A technology for test and model soil, which is applied to the field of test model soil for crushed IV surrounding rock and its preparation field, can solve the problems of easy poisoning, time-consuming model drying, unsuitability for weak and broken rock mass, etc. Strong, easy to operate, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

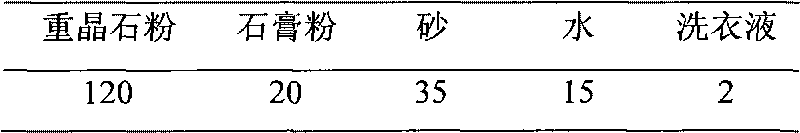

[0058]Use 120g of barite powder, 20g of gypsum powder and 35g of sand and mix evenly, then add 15g of clean tap water, after stirring again, add 2g of laundry detergent and fully combine it with the mixture. The ratio of laundry detergent to water is 1:7.5 , after fully stirring, and then let stand for 2h. The density of the obtained model soil is 2.1g / cm 3 , the cohesion force is 11.47kPa, and the internal friction angle is 29.82°.

[0059]

Embodiment 2

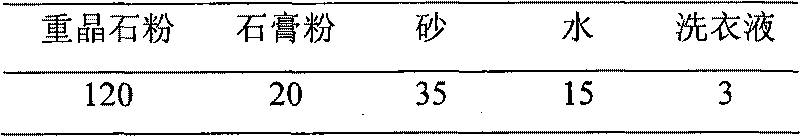

[0061] Use 120g of barite powder, 20g of gypsum powder and 35g of sand and mix evenly, then add 15g of clean tap water, after stirring again, add 3g of laundry detergent and fully combine it with the mixture. The ratio of laundry detergent to water is 1:5 , after fully stirring, and then let stand for 2h. The density of the obtained model soil is 2.1g / cm 3 , the cohesion force is 11.26kPa, and the internal friction angle is 30.34°.

[0062]

Embodiment 3

[0064] Use 120g of barite powder, 20g of gypsum powder and 35g of sand to mix evenly, then add 15g of clean tap water, and after stirring again, add 4g of laundry detergent and fully combine it with the mixture. The ratio of laundry detergent to water is 1:3.75 , after fully stirring, and then let stand for 2h. The density of the obtained model soil is 2.1g / cm 3 , the cohesion force is 10.53kPa, and the internal friction angle is 31.69°.

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Cohesion | aaaaa | aaaaa |

| Angle of internal friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com