Back plate for plasma display

A plasma display and backplane technology, applied in the direction of solid cathode components, etc., can solve the problem of poor size adaptability and achieve the effect of improving size adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

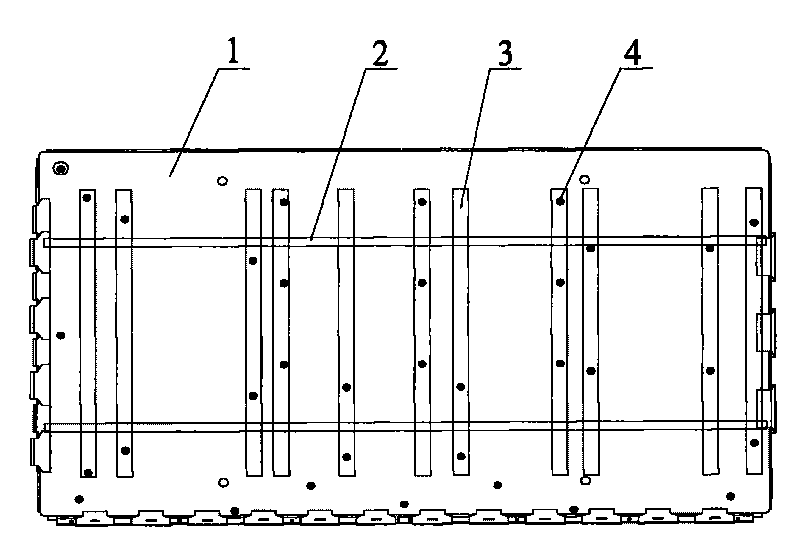

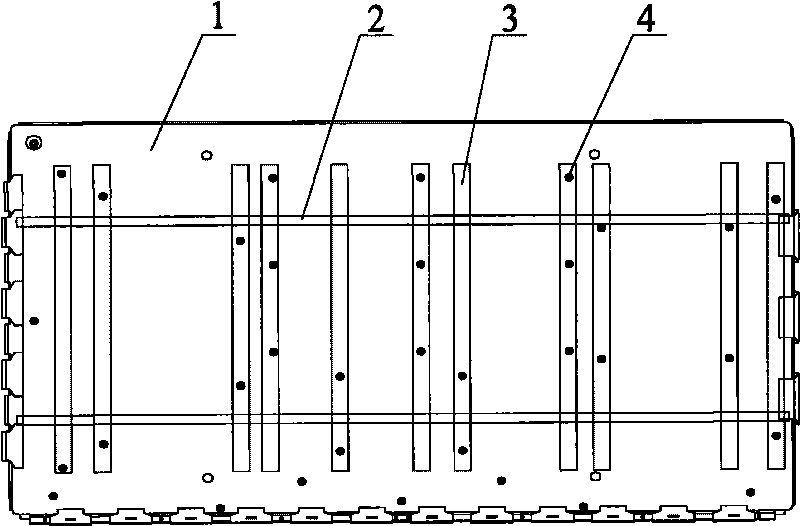

[0018] figure 1 A schematic structural view of a backplane for a plasma display according to a preferred embodiment 1 of the present invention is shown, the backplane includes: a guide rail 2, which is horizontally fixed on the backplane 1; a slide rail 3, which is longitudinally located on the guide rail 2, Suitable for lateral movement along the guide rail 2; stud 4, which is installed on the slide rail 3.

[0019] Wherein, the guide rail 2 is riveted on the backboard 1 .

[0020] In this preferred embodiment, since guide rails and slide rails movable along the guide rails are set on the backplane, the studs are located on the slide rails and can move along the slide rails, the PCB can be fixed by adjusting the positions of the slide rails and studs, which solves the problem There is a problem that the technical backplane has poo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com