Novel secondary refrigerant liquid filling gun

A technology of refrigerant and filling gun, used in liquid distribution, conveying or transfer devices, special distribution devices, packaging, etc. problems, to achieve the effect of suitable promotion and mass production, effective and accurate filling amount, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

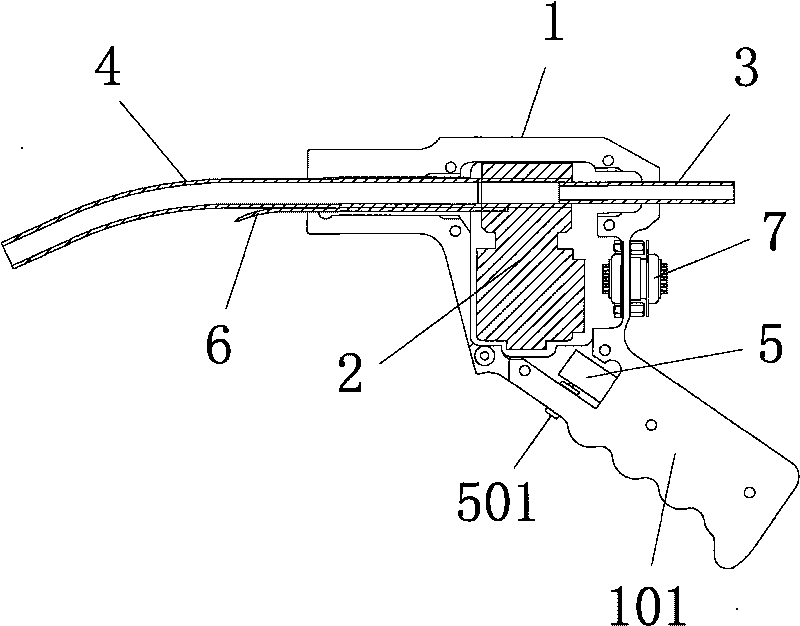

[0023] Example: Combine figure 1 , figure 2 , image 3 and Figure 4 As shown, the new brine liquid filling gun provided in this embodiment includes a gun-shaped housing 1; a solenoid valve 2 is arranged inside the gun-shaped housing 1, and the valve core of the solenoid valve 2 enters, A liquid inlet pipe 3 and a liquid outlet pipe 4 are respectively screwed and fixed on the outlet, the liquid inlet pipe 3 stretches out from the rear end of the gun-shaped housing 1, and the liquid outlet pipe 4 stretches out from the front end of the gun-shaped housing 1, and The part of the liquid outlet pipe 4 protruding from the gun-shaped housing 1 has a downward curved arc. The gun handle 101 of the gun-shaped housing 1 is provided with a micro switch 5 electrically connected to the solenoid valve 2 , and the button 501 on the micro switch 5 protrudes from the gun-shaped housing 1 . The electromagnetic valve 2 is also electrically connected with an anti-overflow electrode 6 , which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com