Thermostatic valve core and self-heating metal thermostatic tap made by using same

A thermostatic valve core and metal technology, applied in valve heating/cooling devices, valve operation/release devices, valve details, etc., can solve problems such as low temperature control accuracy, waste of water resources, and inconvenience for customers. Achieve the effects of high temperature control accuracy, reasonable structural design, and water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

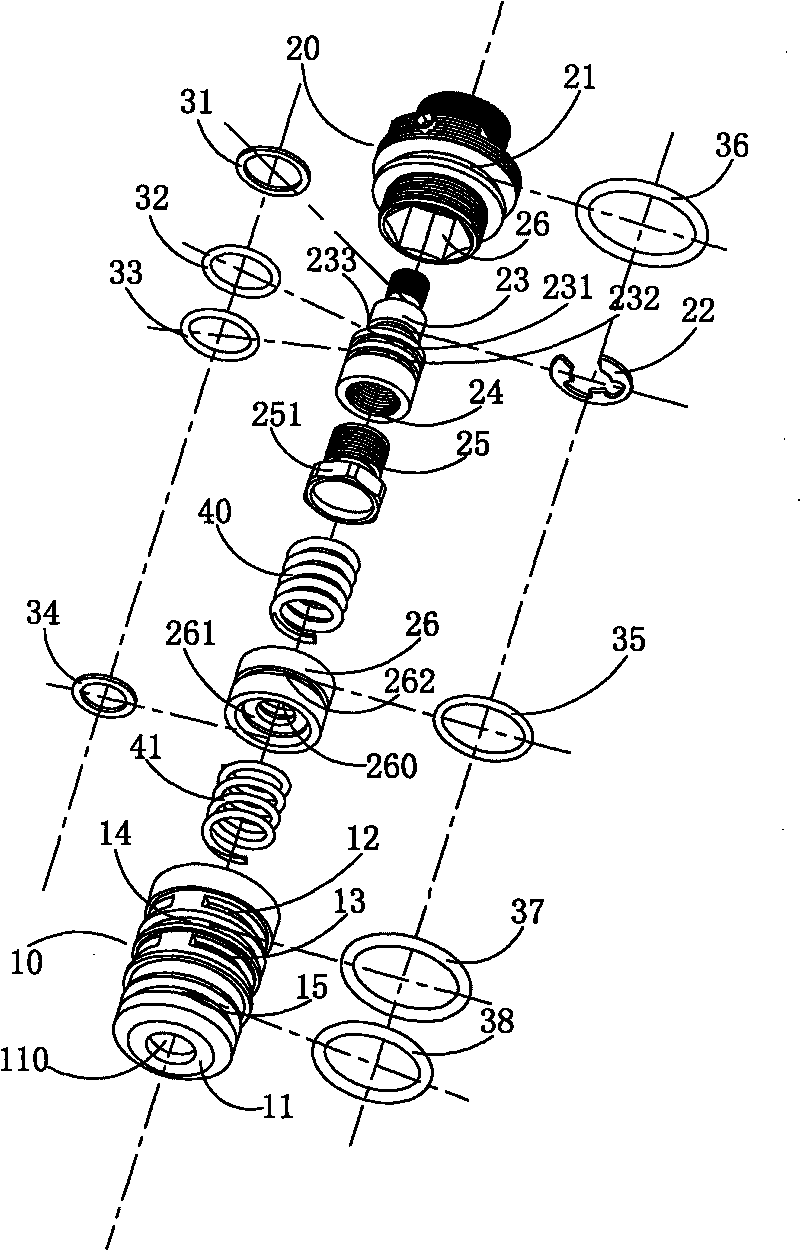

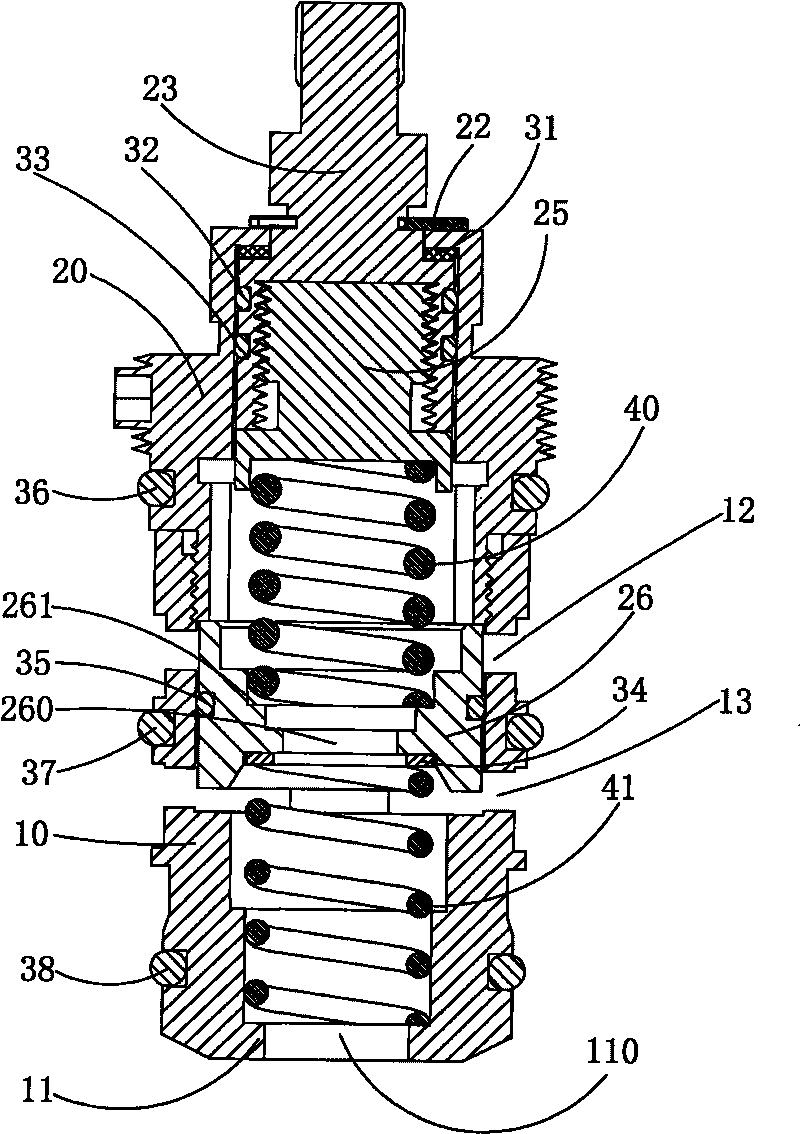

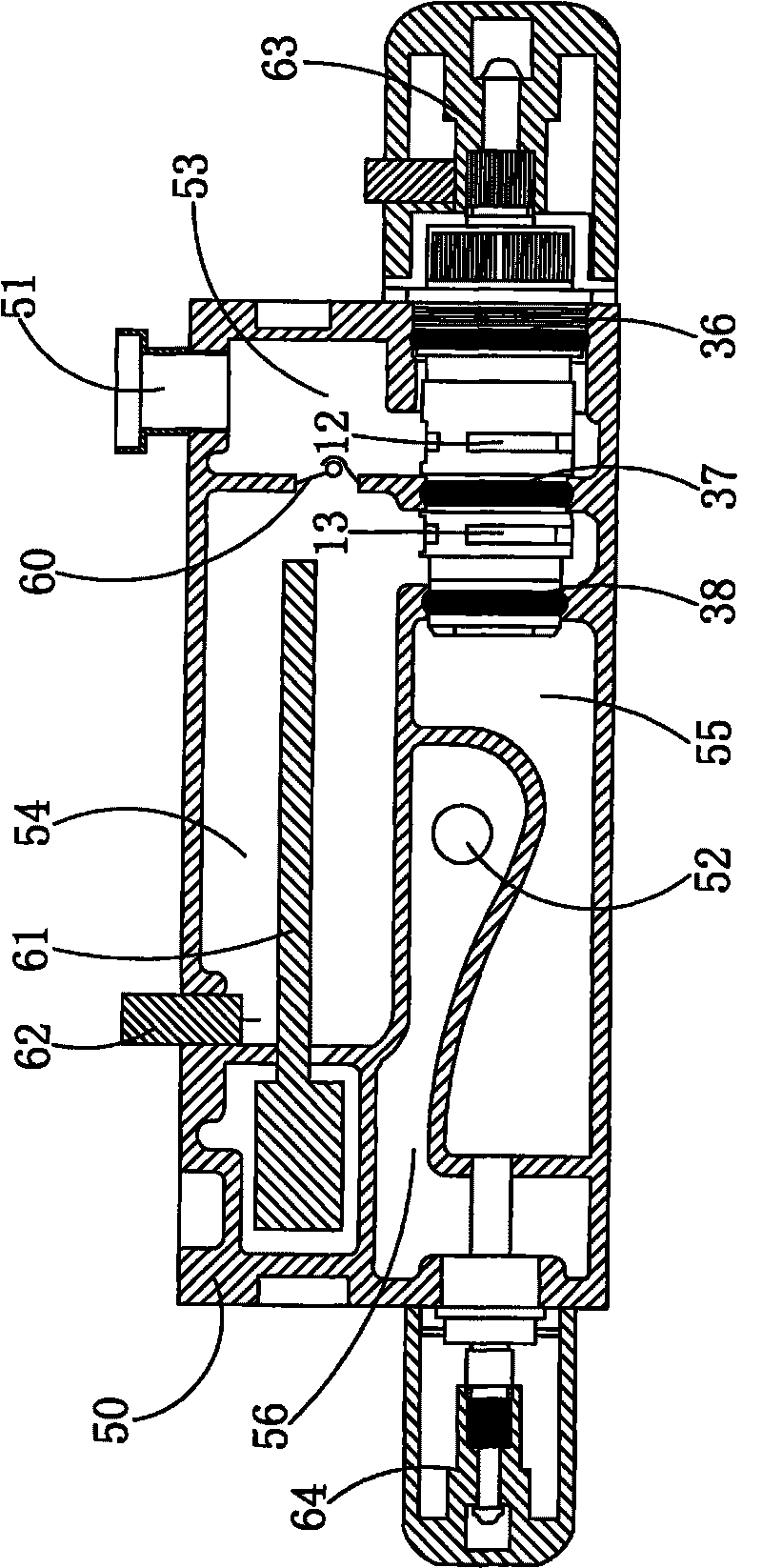

[0024] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-3 :

[0025] The thermostatic spool has a spool cover 20 fixedly connected to one end of the cylindrical spool seat 10 , a sealing groove 21 is provided on the outer cylindrical surface of the spool cover 20 , and the other end of the spool cover 20 is clamped by a snap spring 22 There is a valve stem 23, one end of the valve stem 23 is clamped in the valve core cover 20 and sealing rings 32, 33 and wear-resistant gaskets 31 are arranged between the valve core cover 20, and the valve stem 23 in the valve core cover 20 One end is connected with a spool 25 through a screw thread 24, a sliding track 26 and a guide block 251 that cooperate with each other are provided between the spool 25 and the spool cover 20, and a plunger is arranged on the other end of the spool 23 in the spool seat 10. 26, between the spool 25 and the plunger 26 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com