Connecting construction method for assembled-type house building

A construction method and prefabricated technology, applied in the direction of building structures, buildings, columns, etc., can solve problems such as the impact of earthquake resistance level, scattered structural force transmission, and unclosed connection parts, so as to improve the overall performance and earthquake resistance level, and facilitate construction , Improve the effect of anti-corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

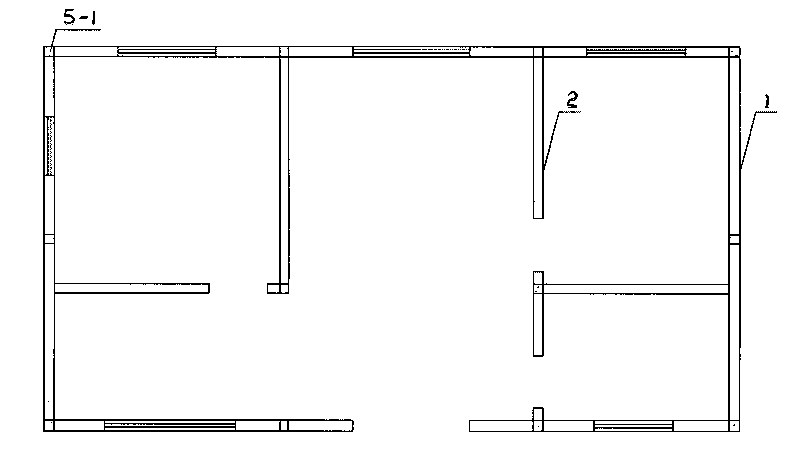

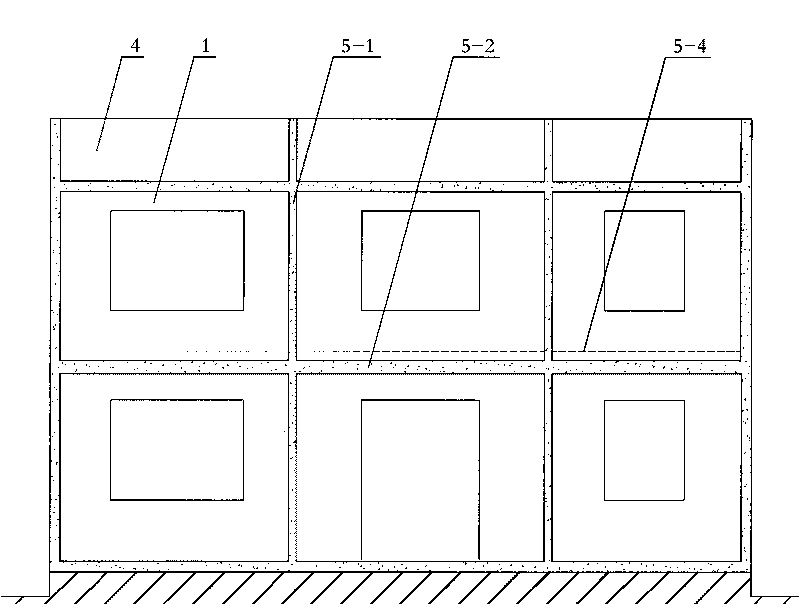

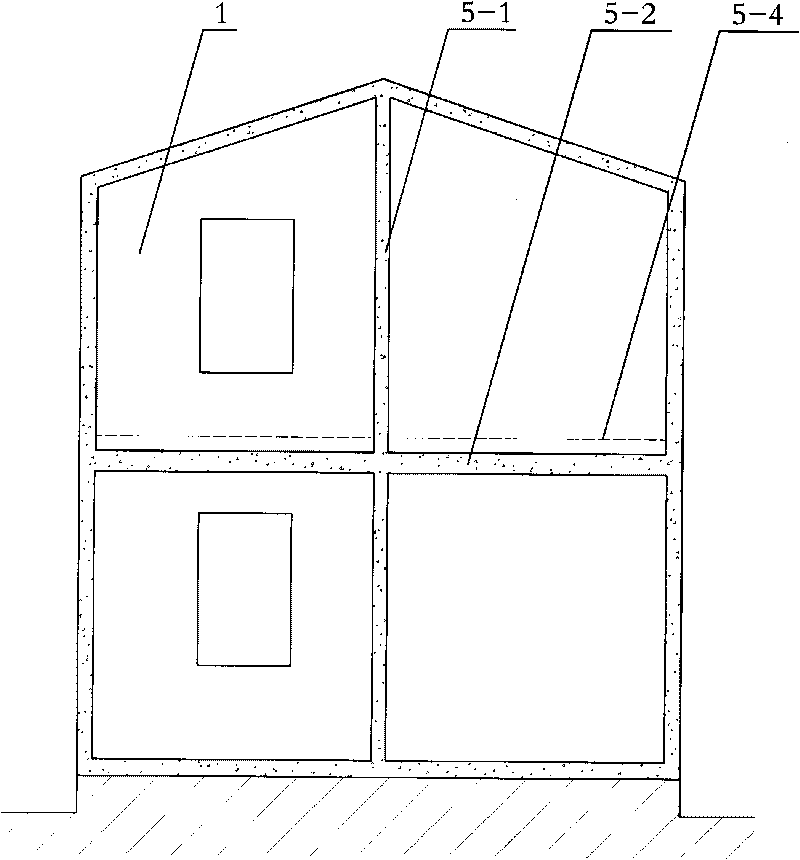

[0030] like figure 1 , figure 2 , image 3 As shown, the prefabricated residential structure of the present invention is mainly composed of exterior wall panels 1, partition wall panels 2, floor slabs 3, roof panels 4, composite concrete structural columns 5-1, composite concrete structural beams 5-2 and floor concrete Layers 5-4 are constructed. The connection construction method of the building panel prefabricated house is:

[0031] When installing the building boards, distance between adjacent building boards (outer wall board 1, partition wall board 2, floor board 3, roof board 4); Main reinforcement 7; pour concrete 5-3 again to form composite concrete structural column 5-1 and composite concrete structural beam 5-2; pass building board (outer wall board 1, partition wall board 2, floor slab 3, roof board 4) The surrounding stirrups 6, the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com