Connection construction method of concrete caisson and steel caisson

A construction method and concrete technology, which is applied in caissons, infrastructure engineering, construction, etc., can solve the problems of difficult positioning of short steel bars, time-consuming and laborious, and easy damage of pouring concrete, and achieve the effect of fast construction, accurate positioning, and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings.

[0019] refer to figure 1 , 2 , the concrete steps of the present invention are:

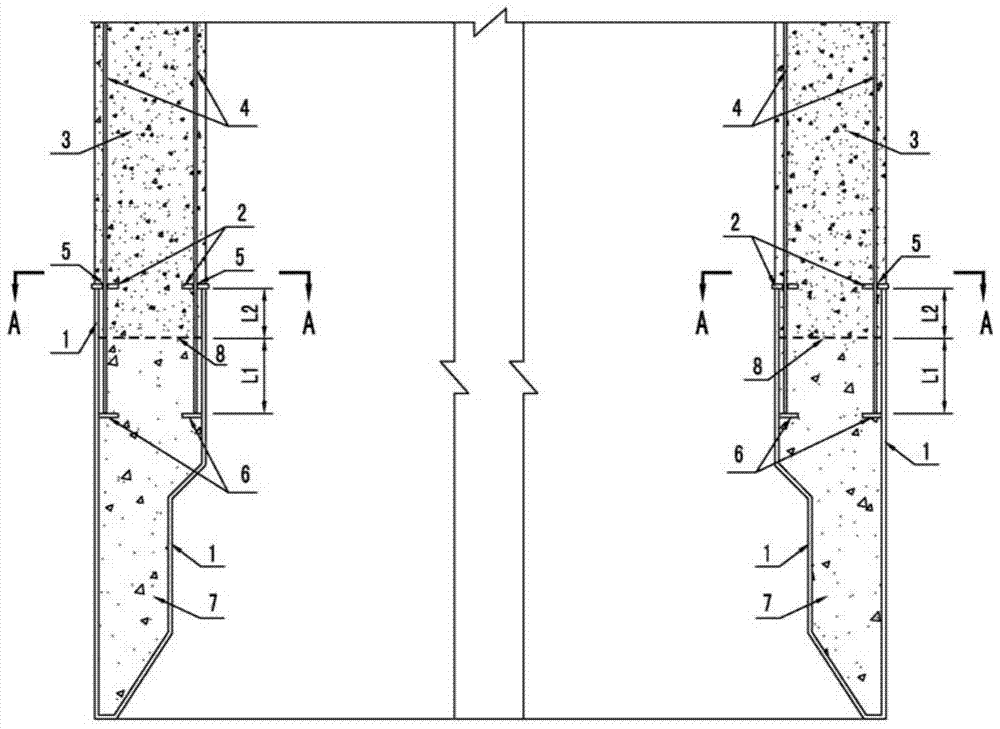

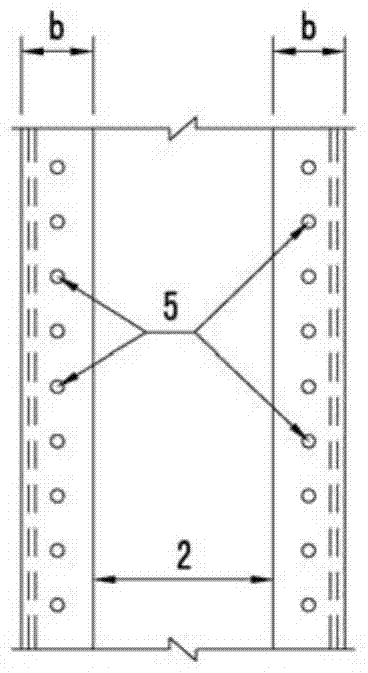

[0020] 1) During the manufacture of the steel caisson 1, a round hole 5 is opened on the horizontal ring rib 2 at the top of the steel caisson for the vertical reinforcement of the concrete caisson to pass through, and the round hole is opened according to the layout of the vertical reinforcement of the concrete caisson 3 ;

[0021] 2) Insert the vertical steel bar 4 of the concrete caisson 3 into the round hole 5 of the horizontal ring rib on the top of the steel caisson, and the lower end of the vertical steel bar is supported on the second horizontal ring rib 6; the second horizontal ring rib The vertical distance to the top horizontal ring rib should not be less than the sum of L1 and L2;

[0022] Where L1 is the anchorage length of the vertical reinforcement, and L2 is twice the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com